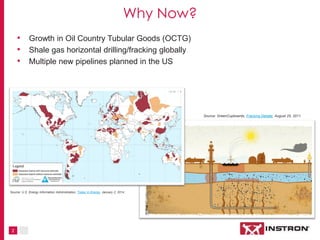

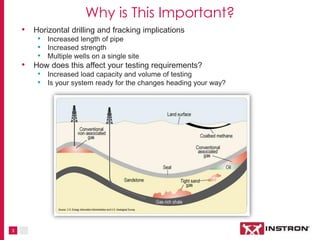

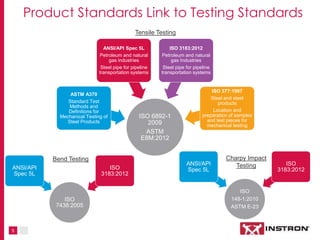

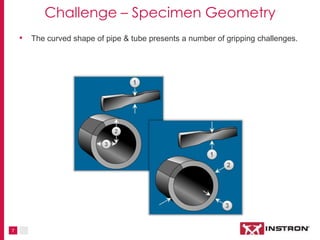

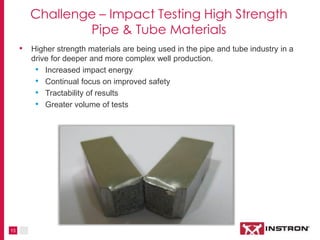

The document discusses the challenges faced by pipe and tube manufacturers due to growth in oil country tubular goods and changes in drilling techniques. Key issues include the need for increased load capacity testing, the complexity of specimen geometry, and the challenges of measuring strain in curved specimens. It highlights the importance of adapting testing methods and standards to ensure efficiency and accuracy in the face of these changes.