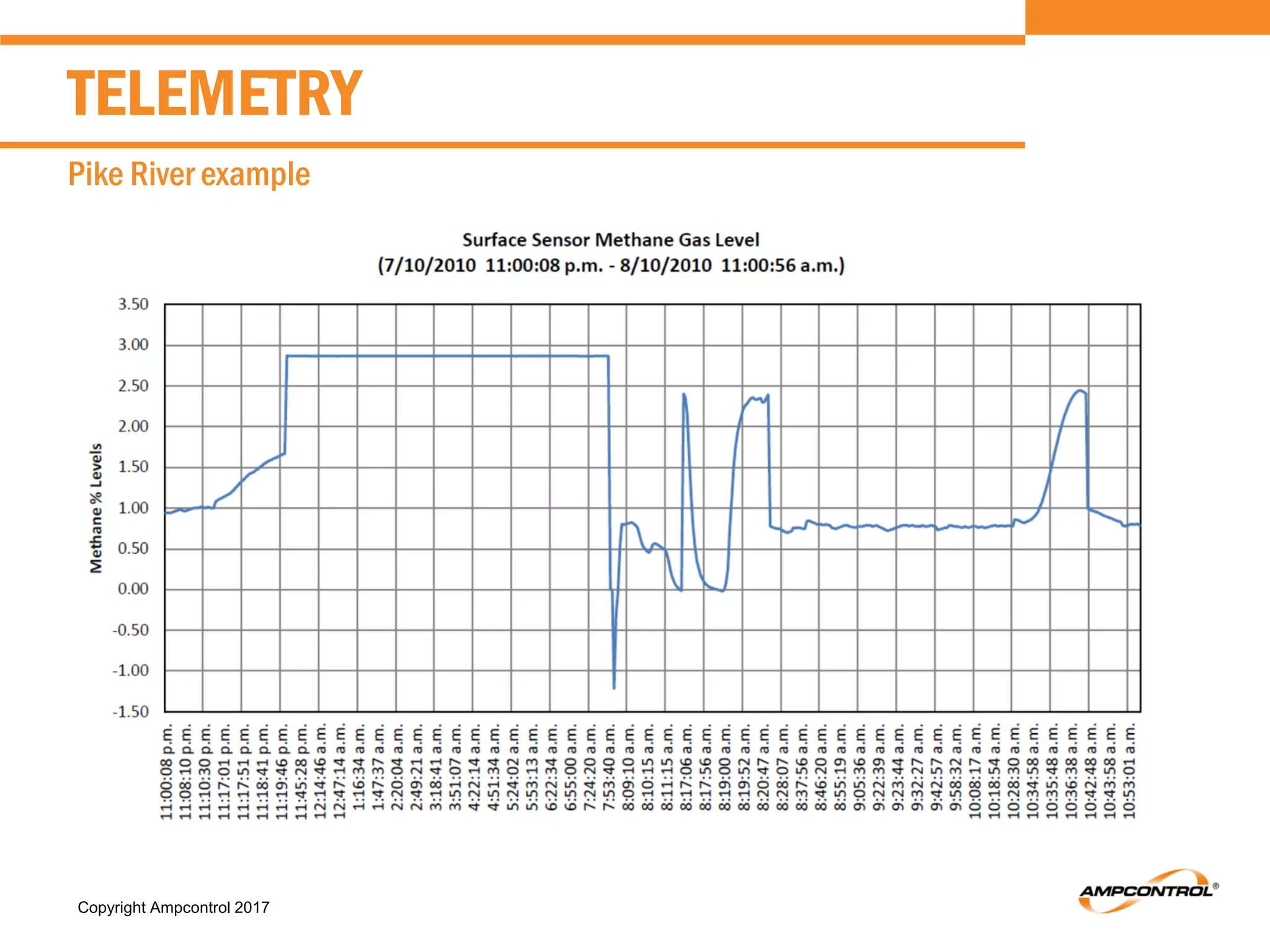

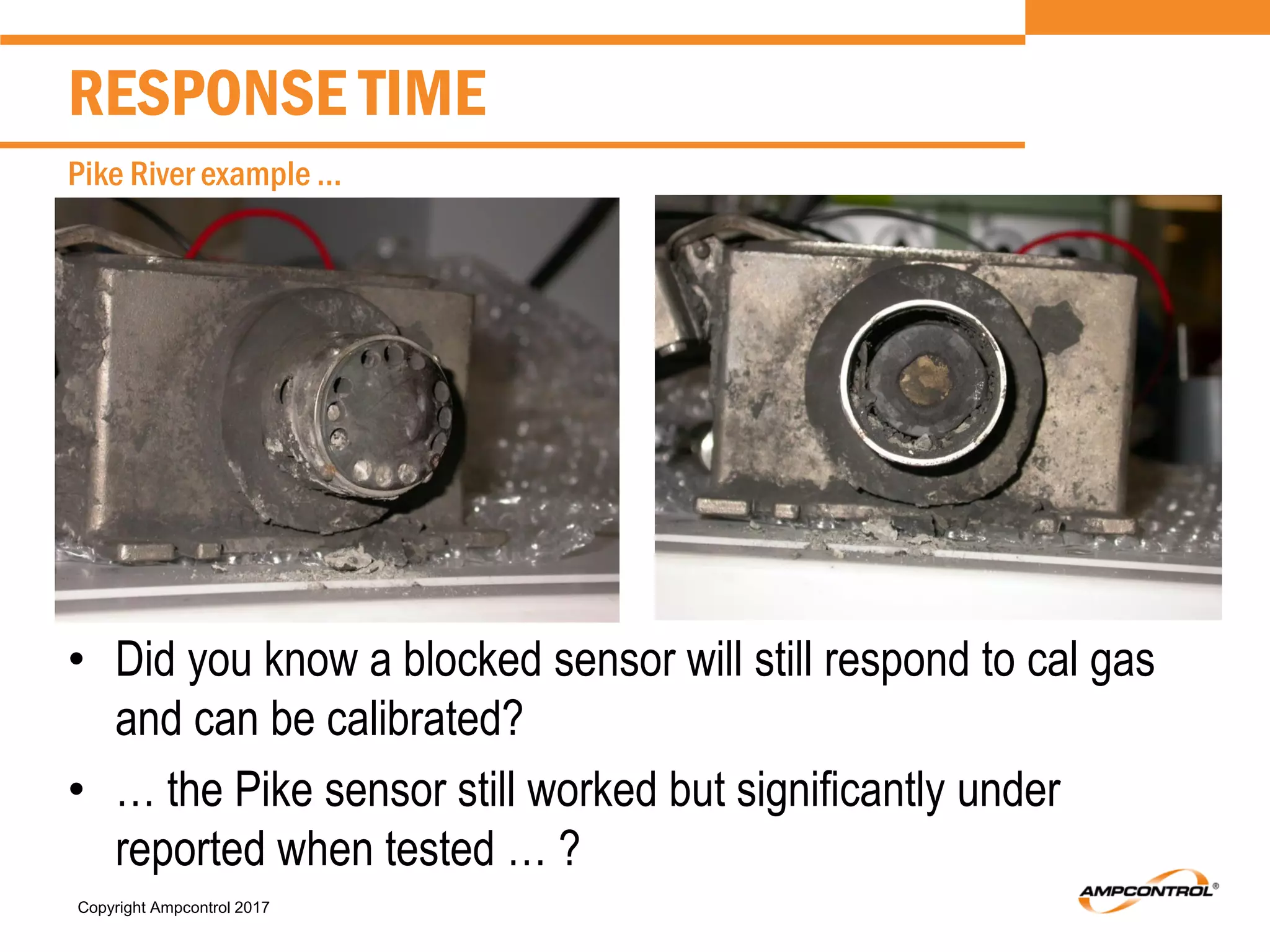

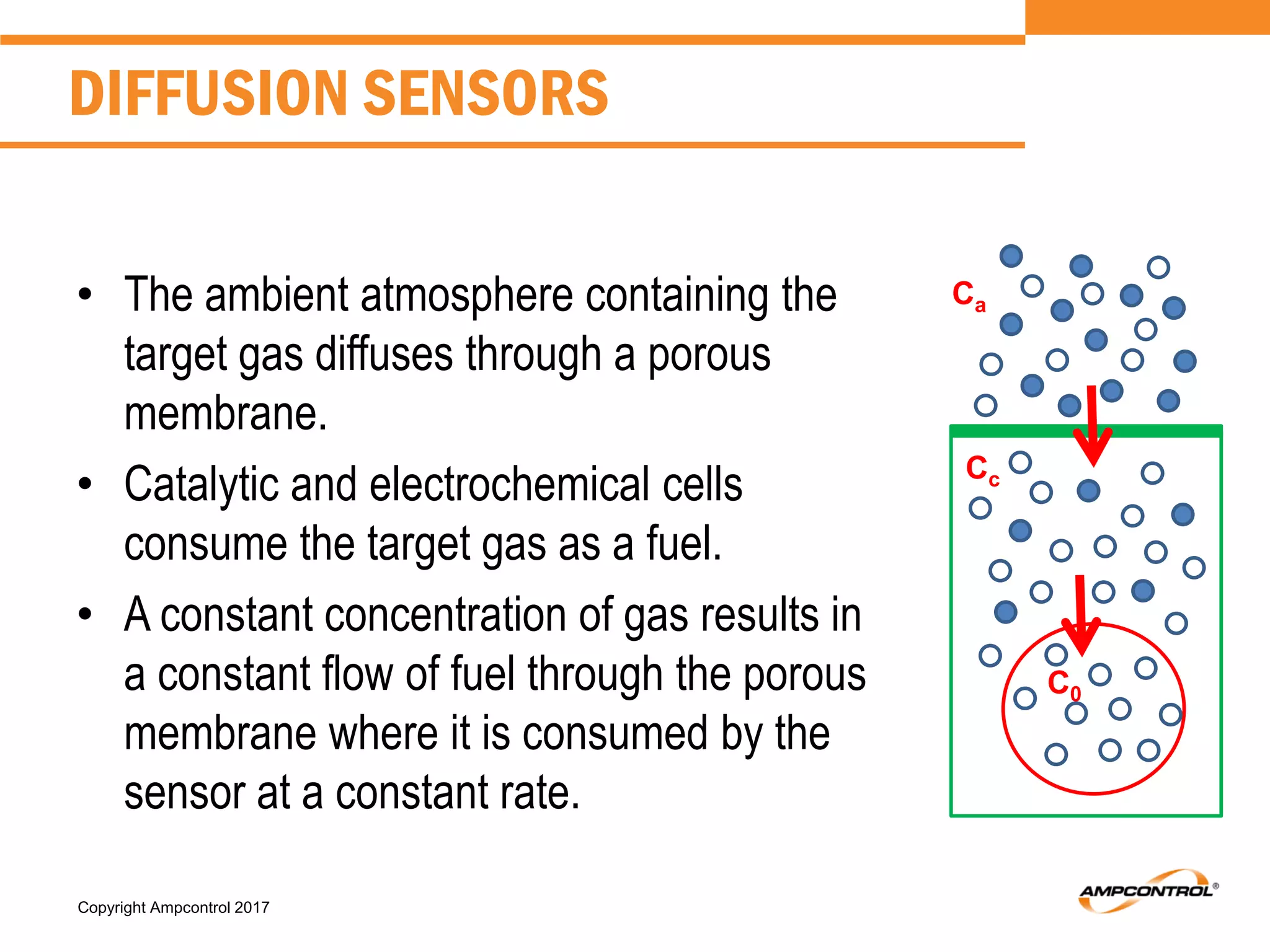

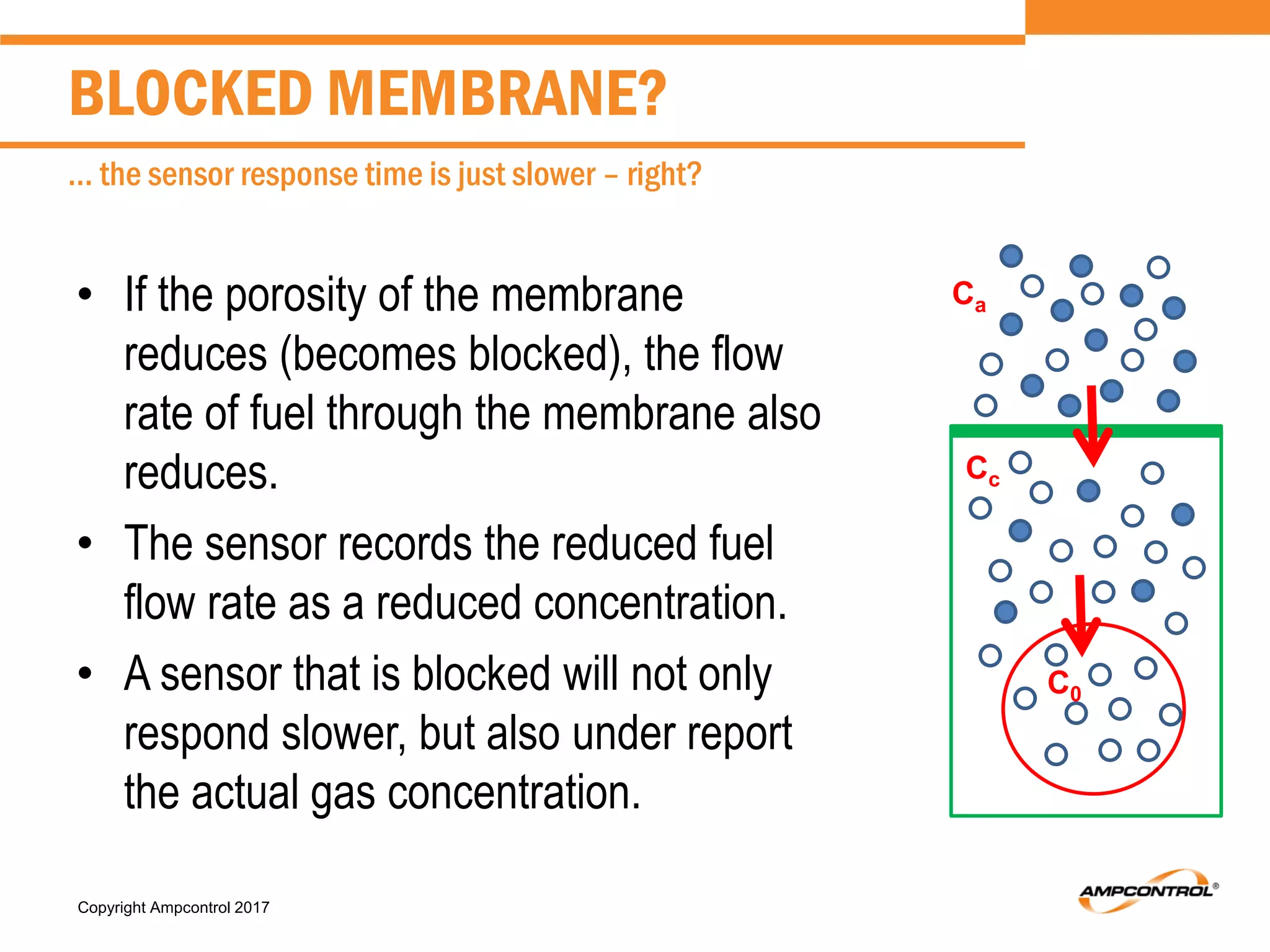

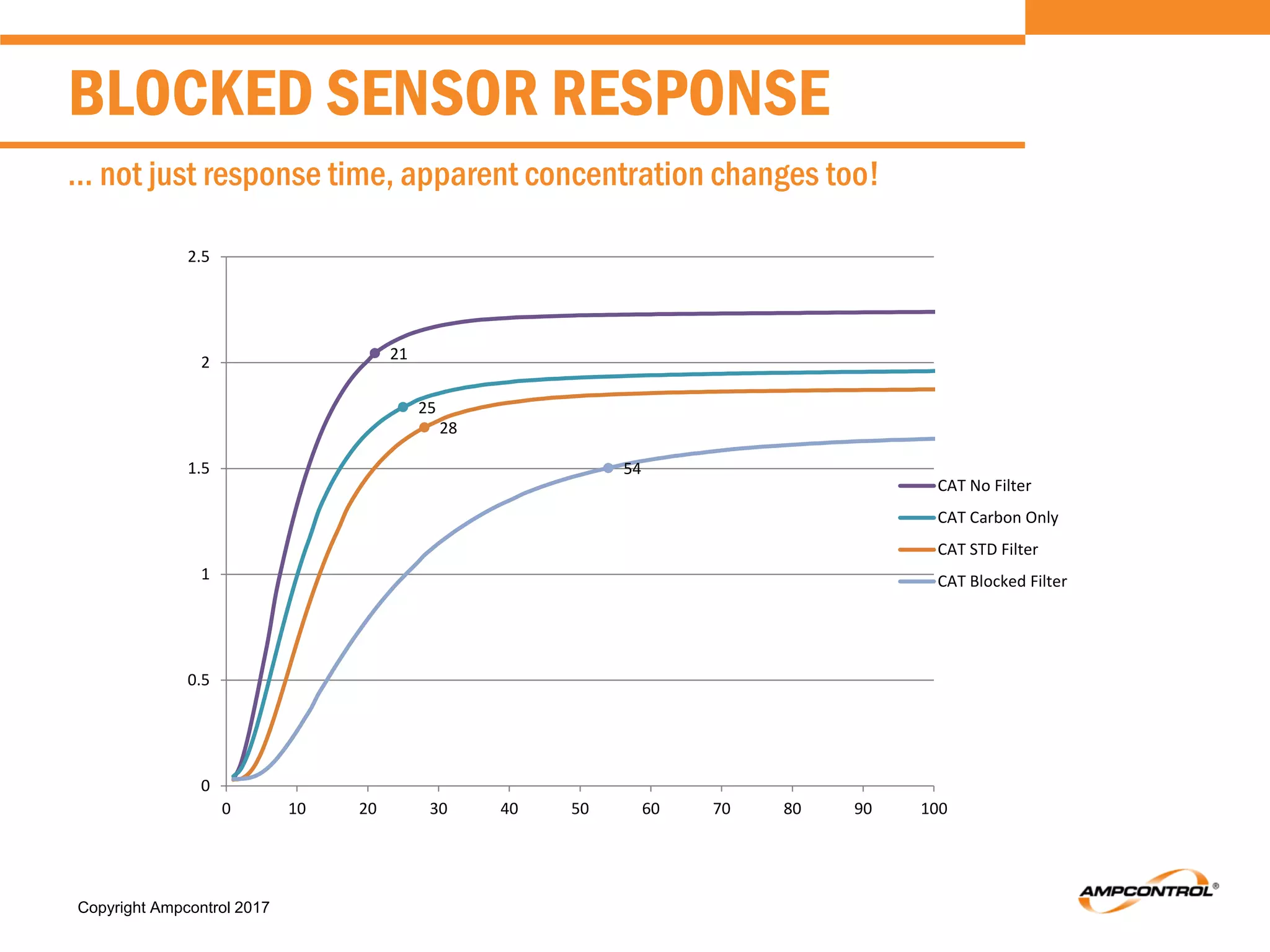

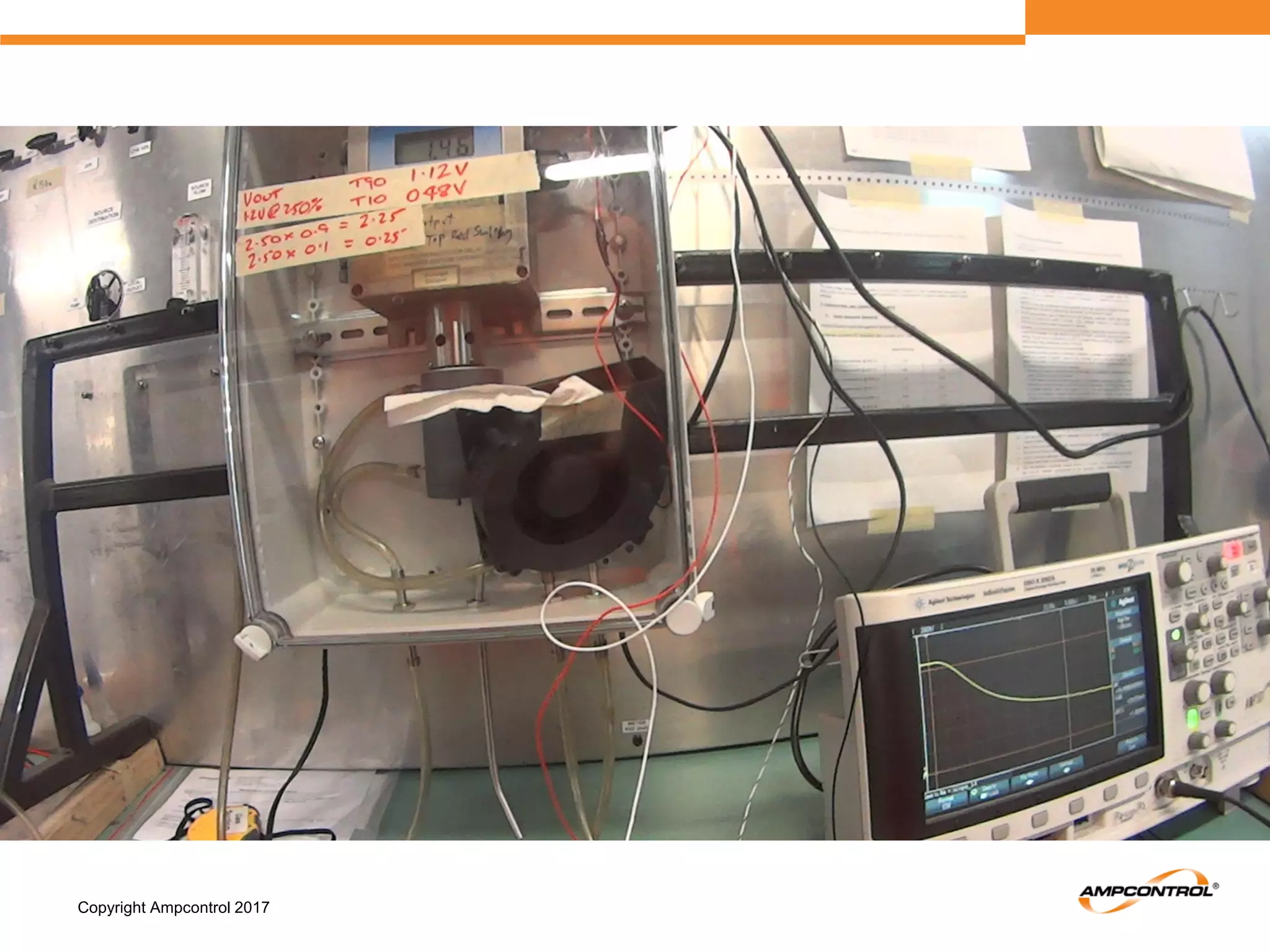

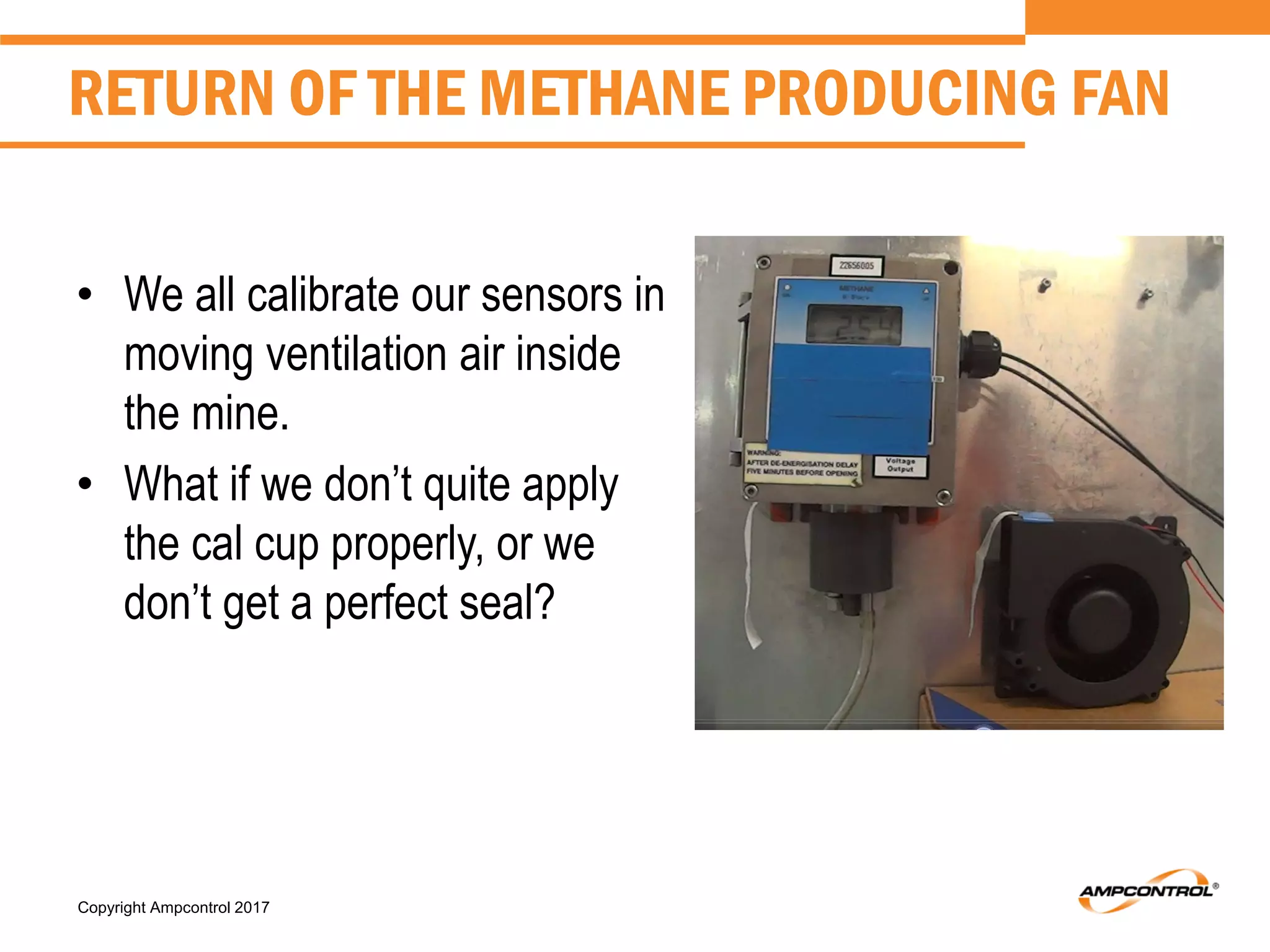

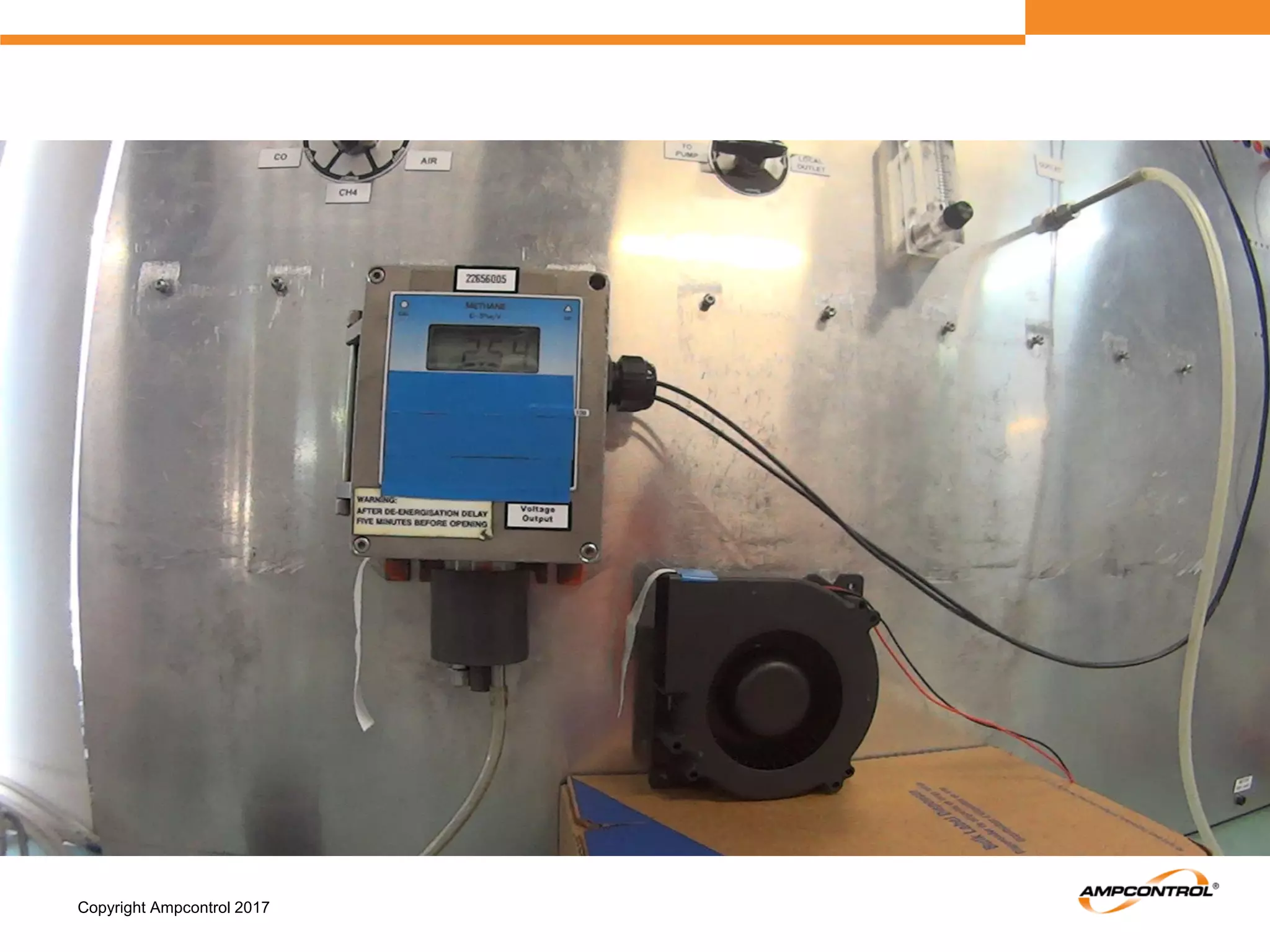

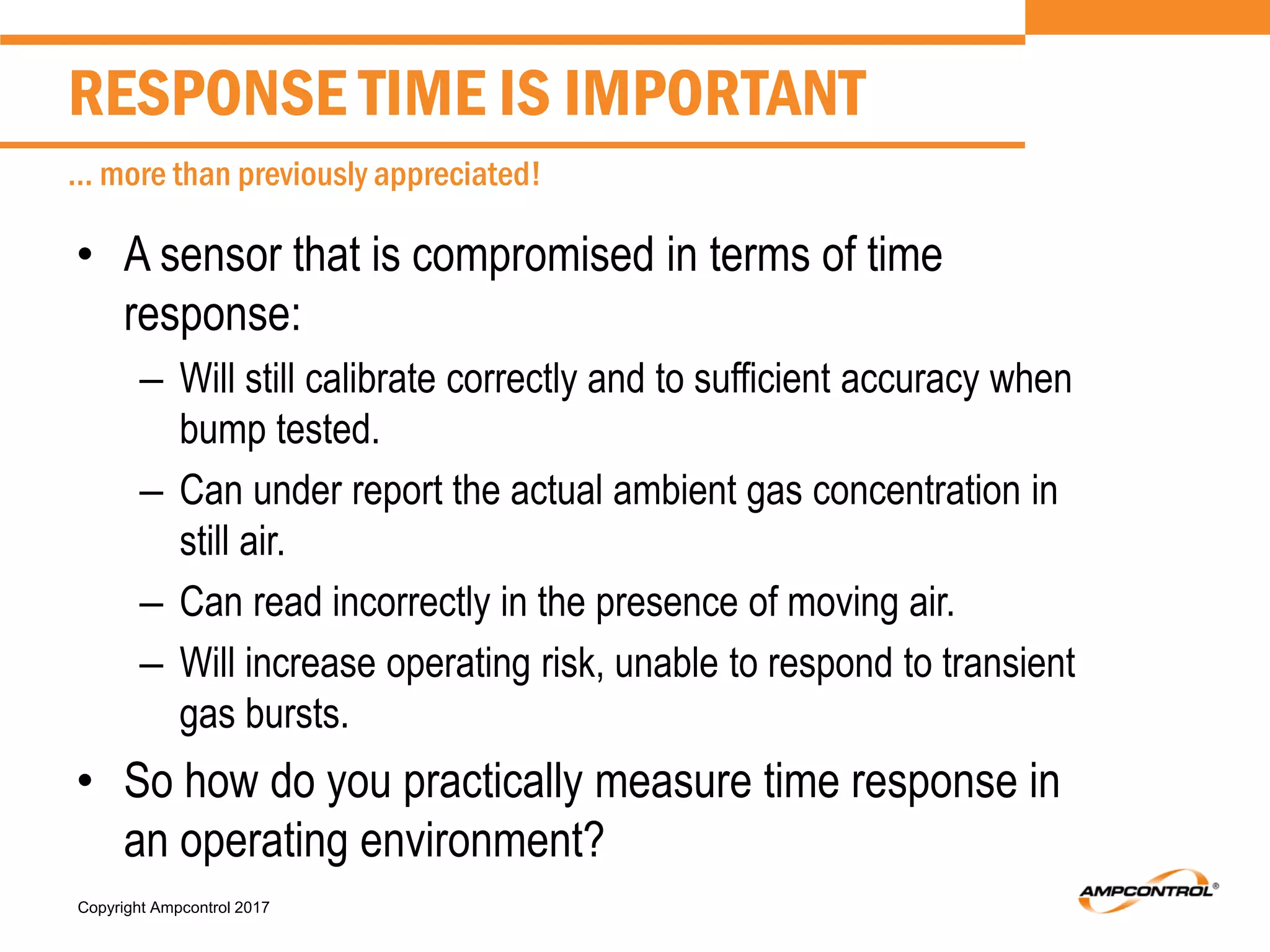

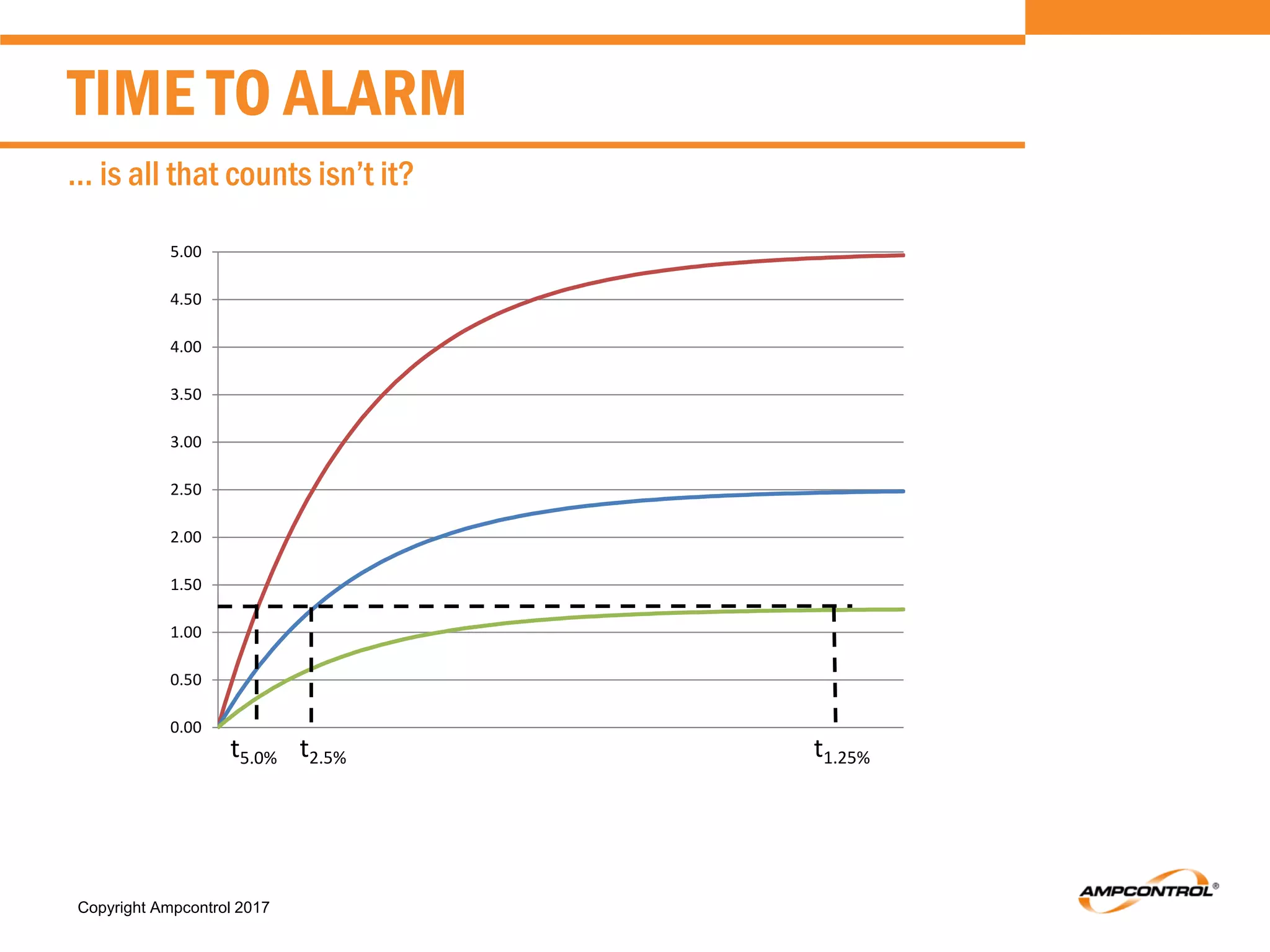

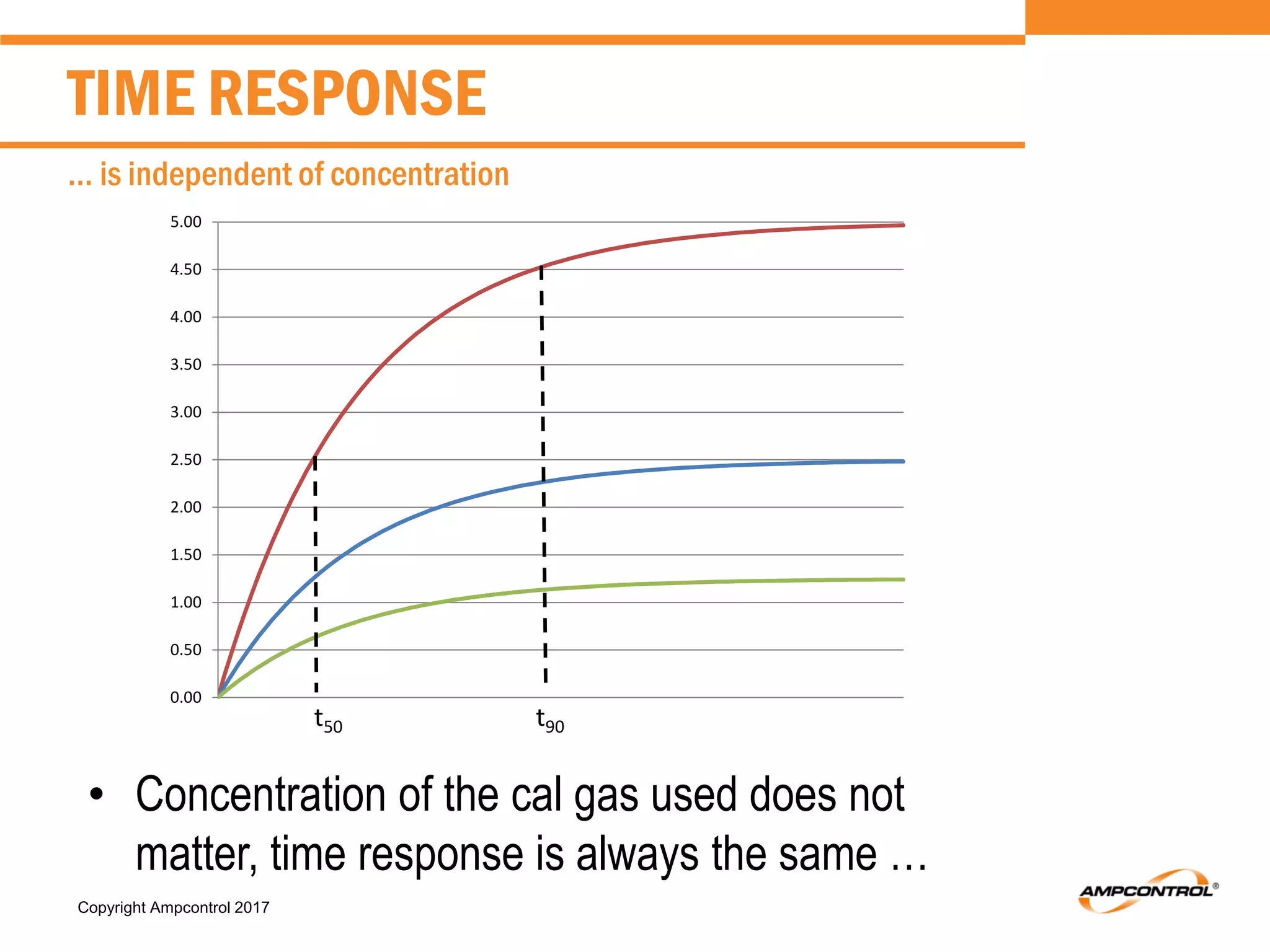

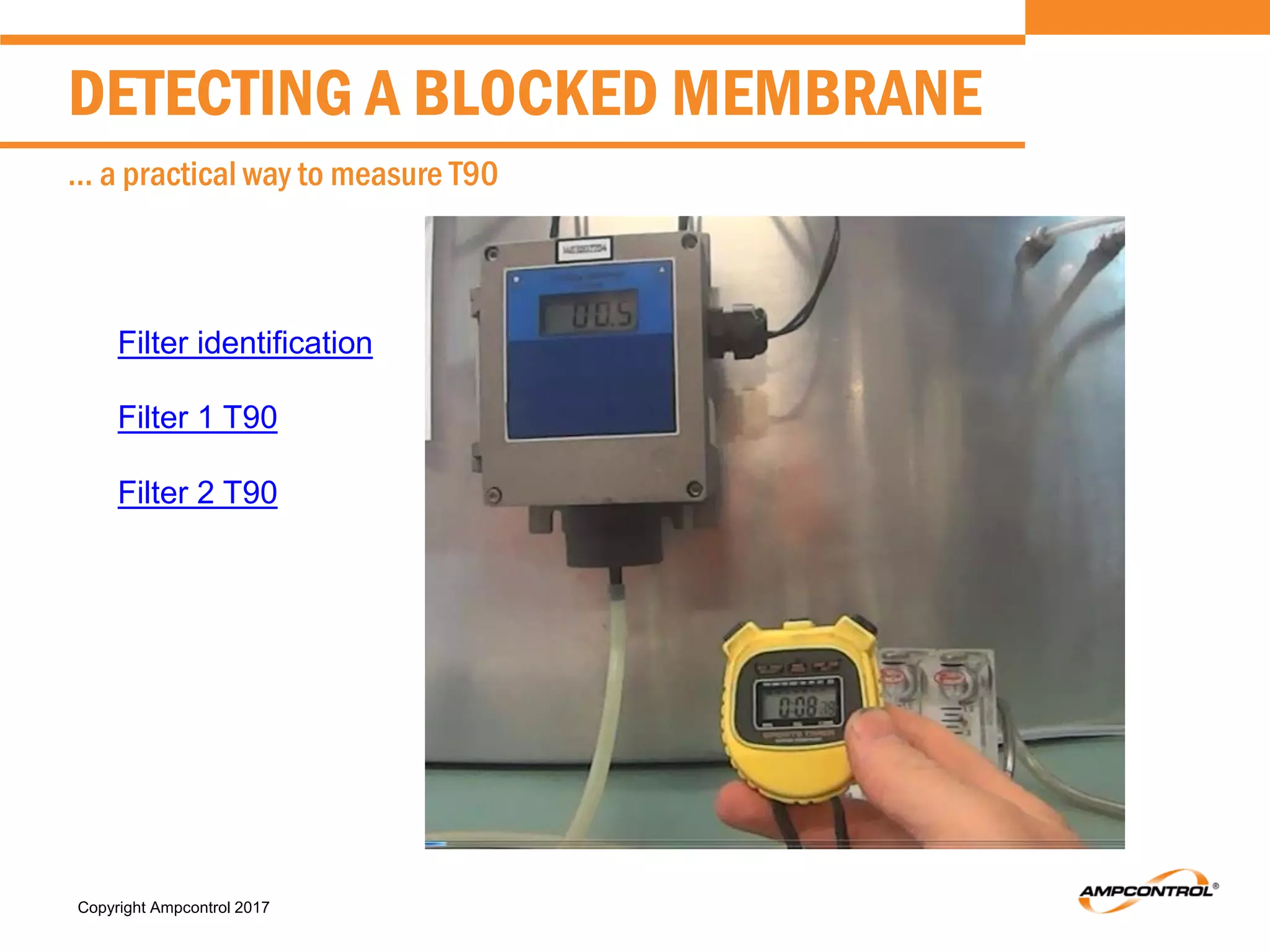

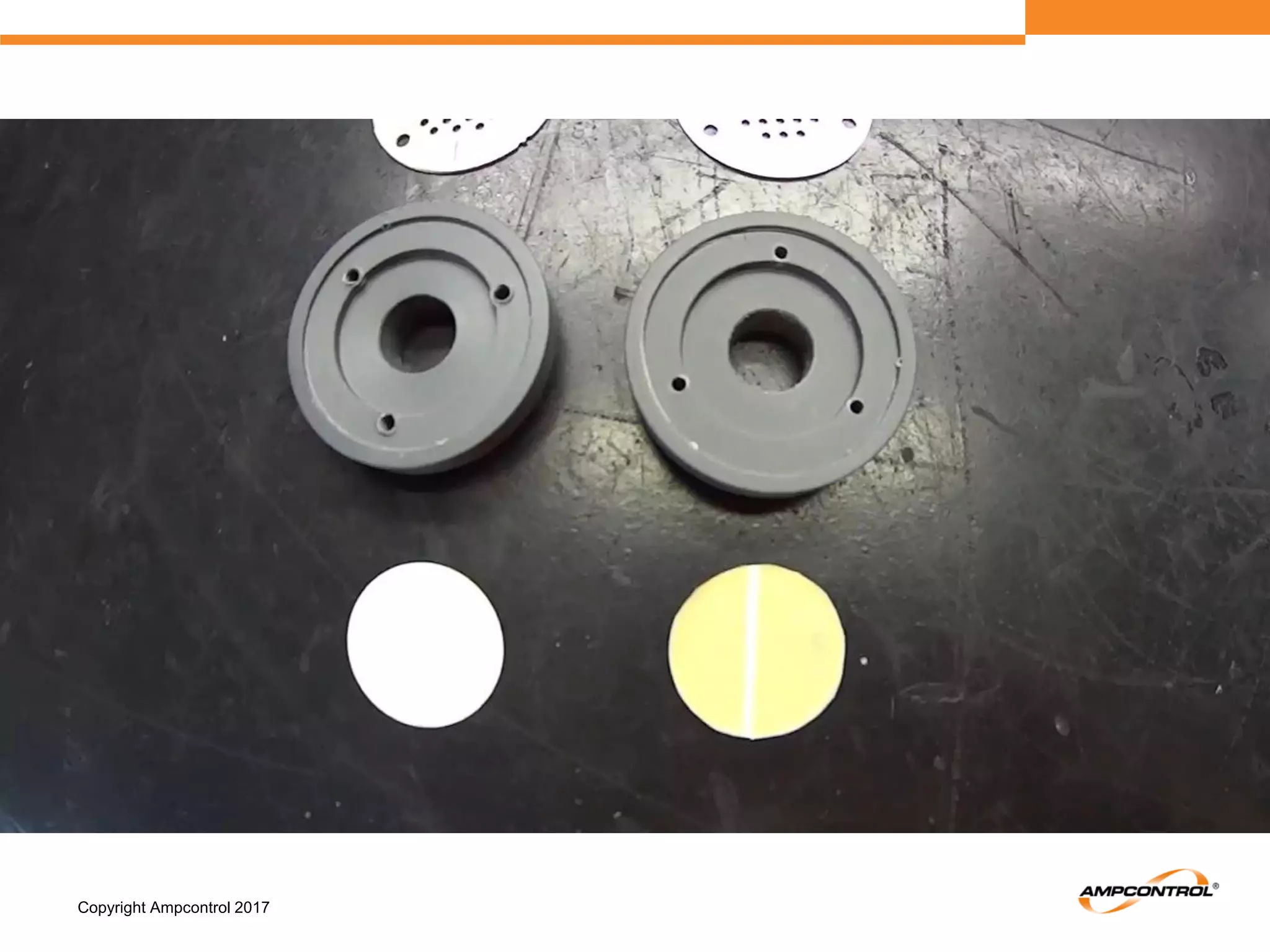

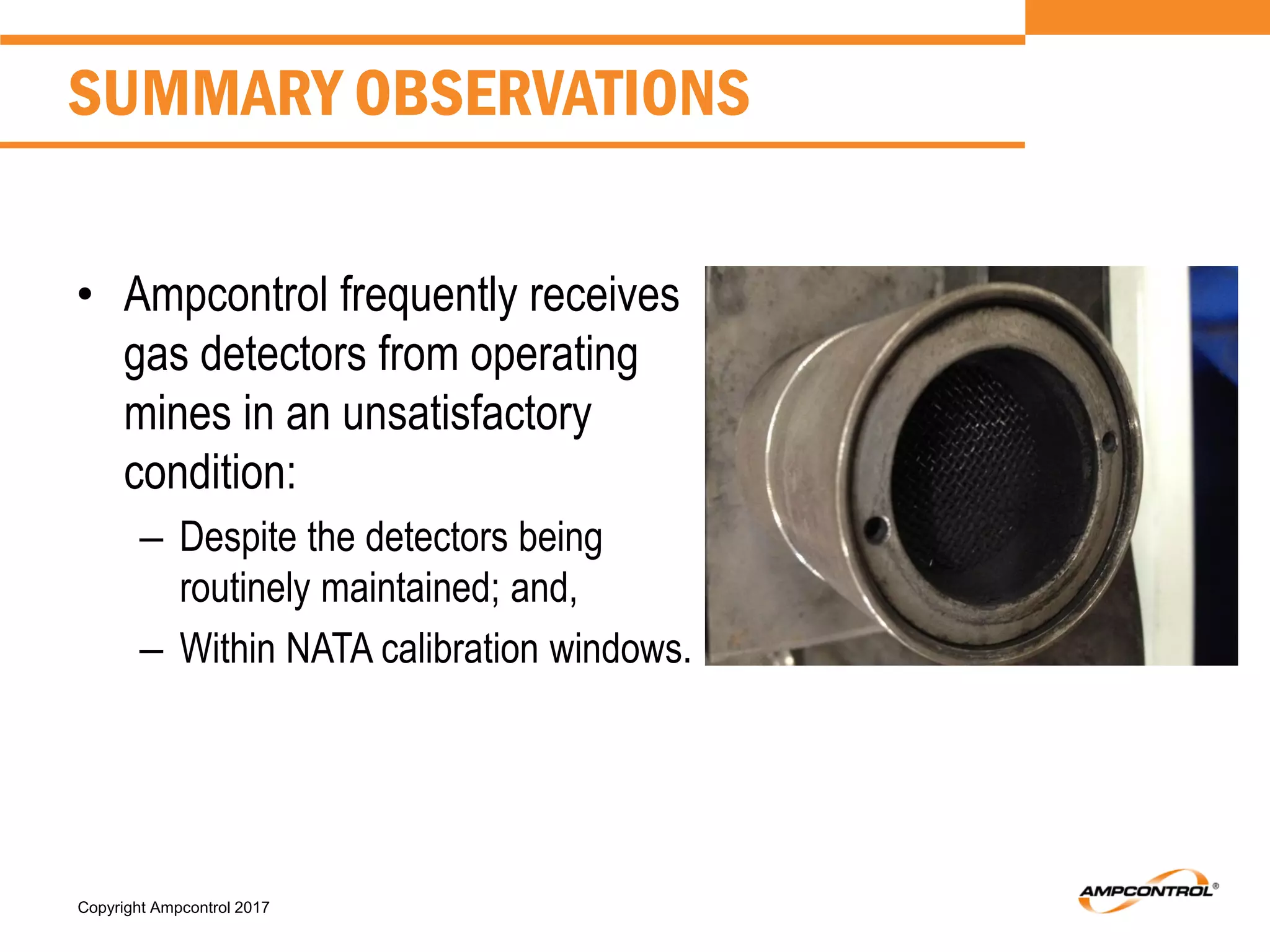

Gas detectors must accurately sense gas concentration, transmit readings, and signal alarms in a timely manner. Regular maintenance focuses on accuracy, but standards now require testing telemetry and response time as well. A blocked sensor may calibrate correctly but under-report concentration in still air or give incorrect readings in moving air. Response time is important for detecting transient gas bursts but is often overlooked in maintenance. Practical testing of response time is needed to ensure gas detectors are fully functional.