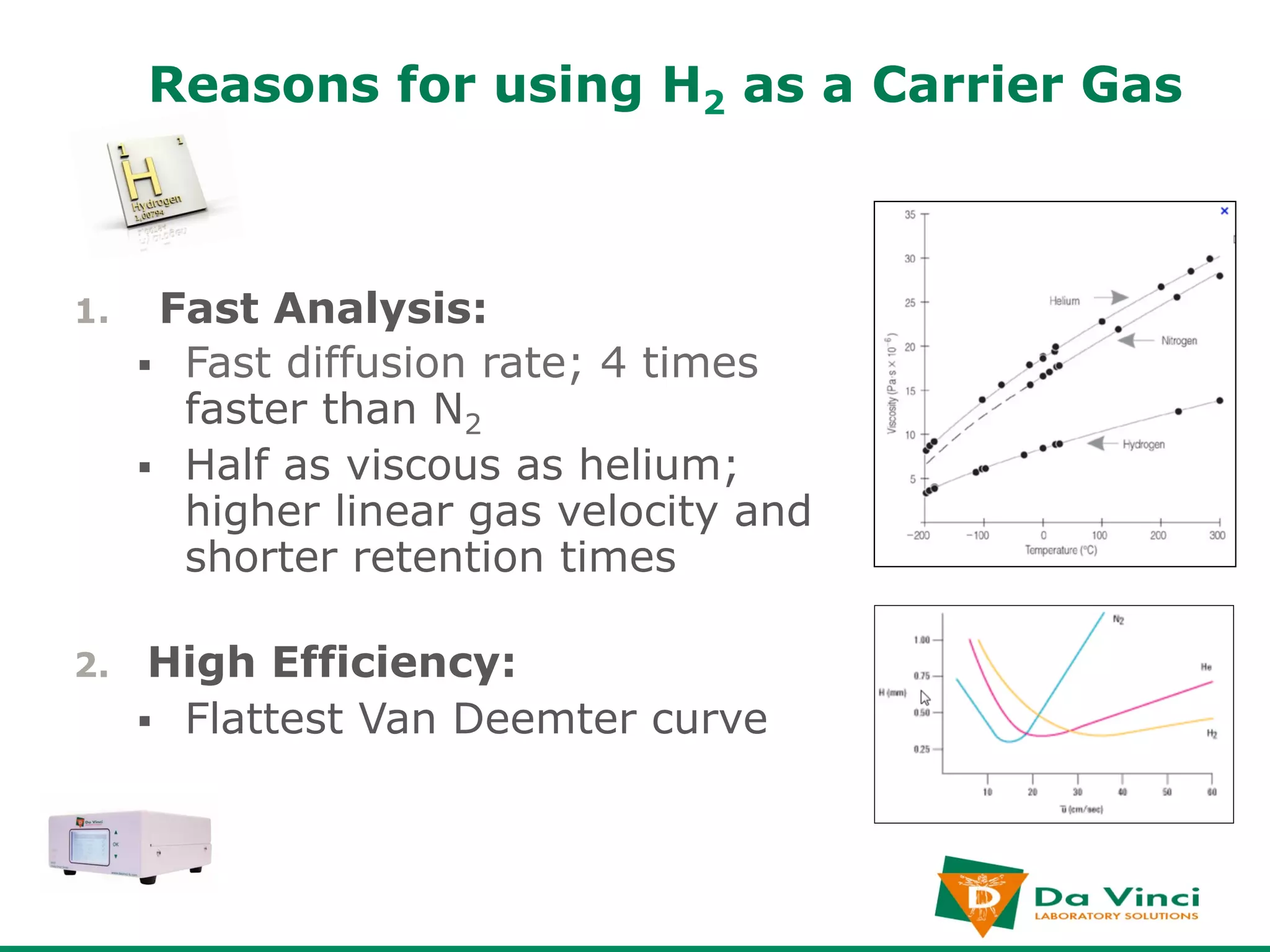

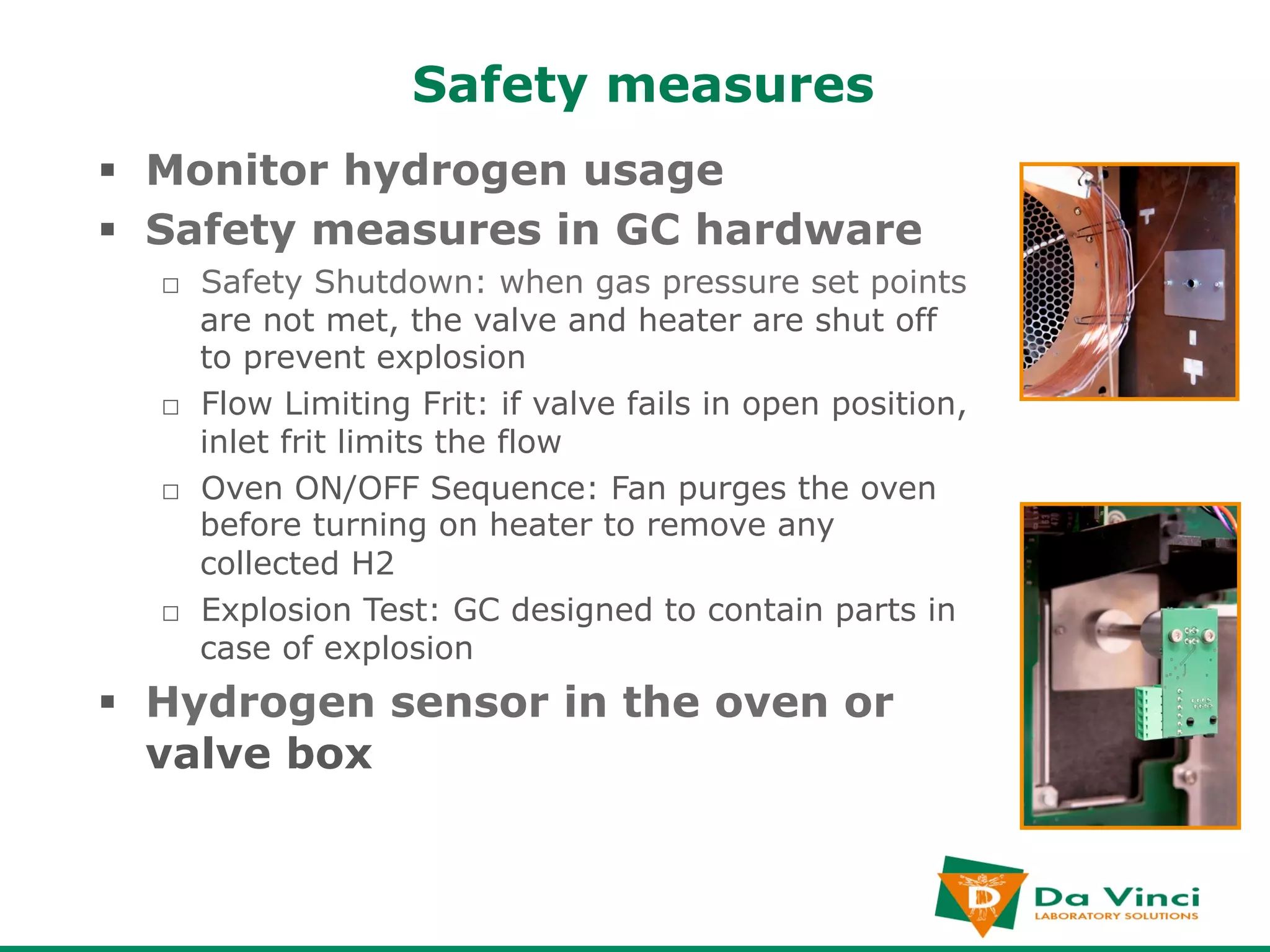

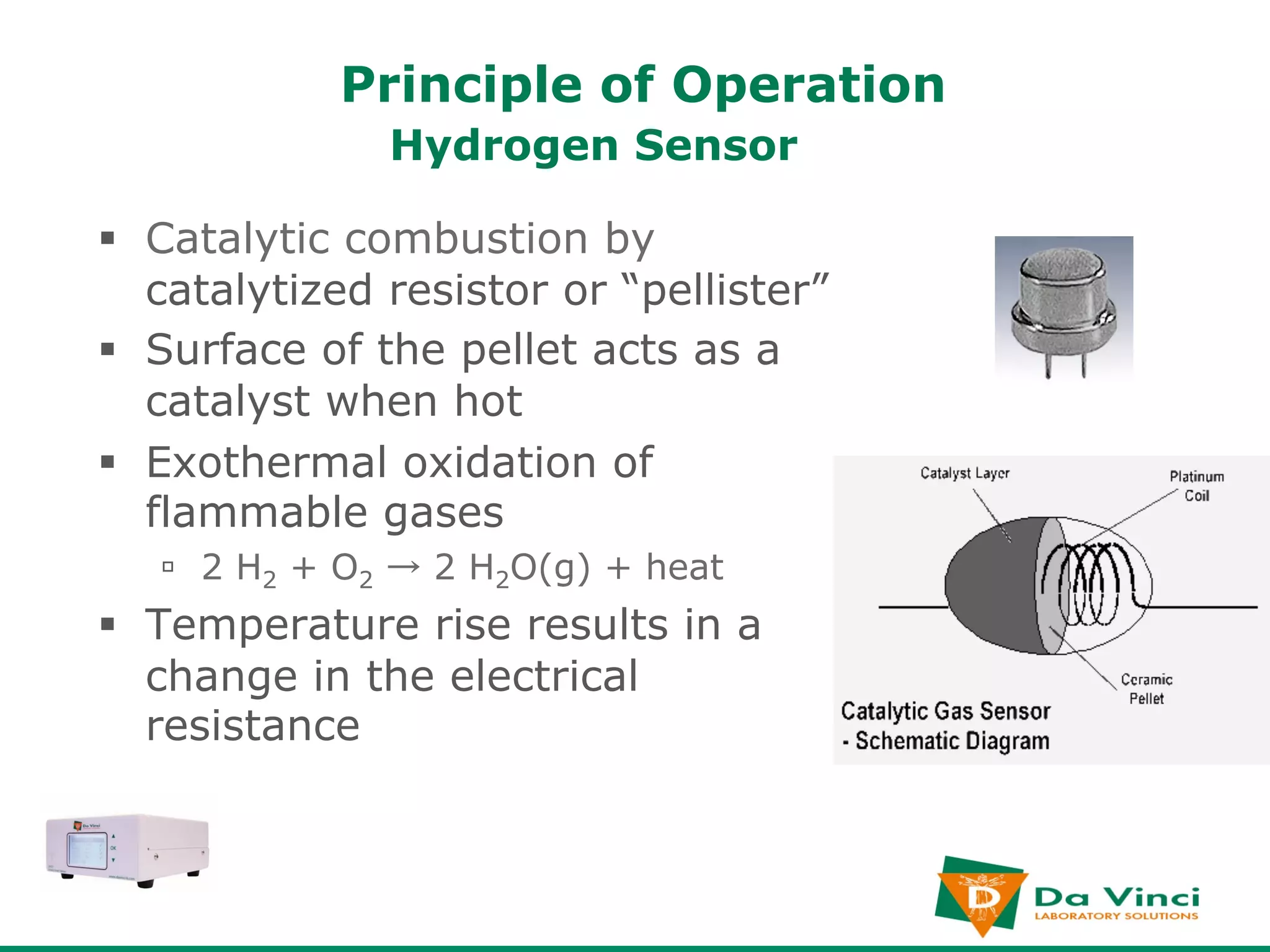

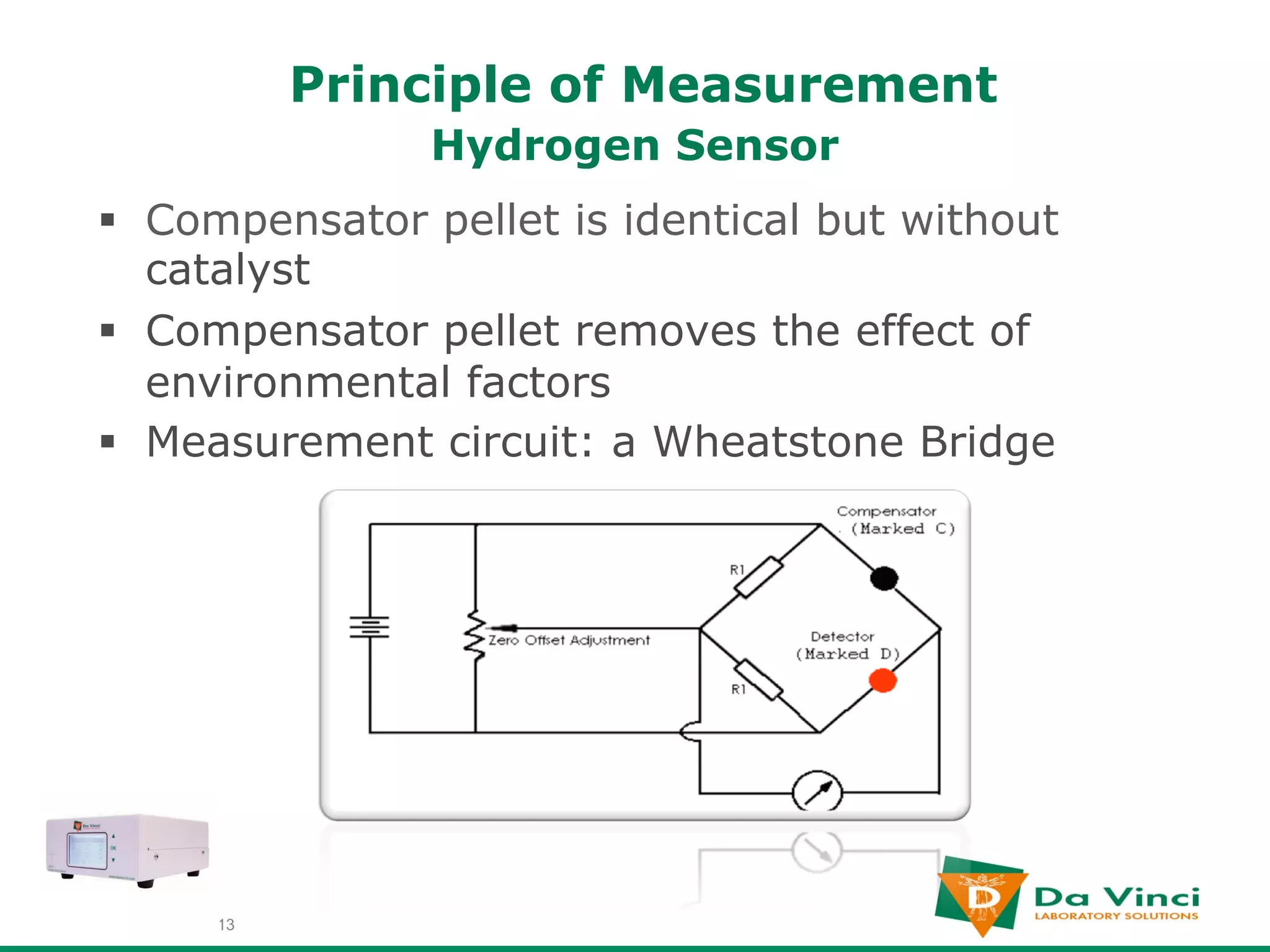

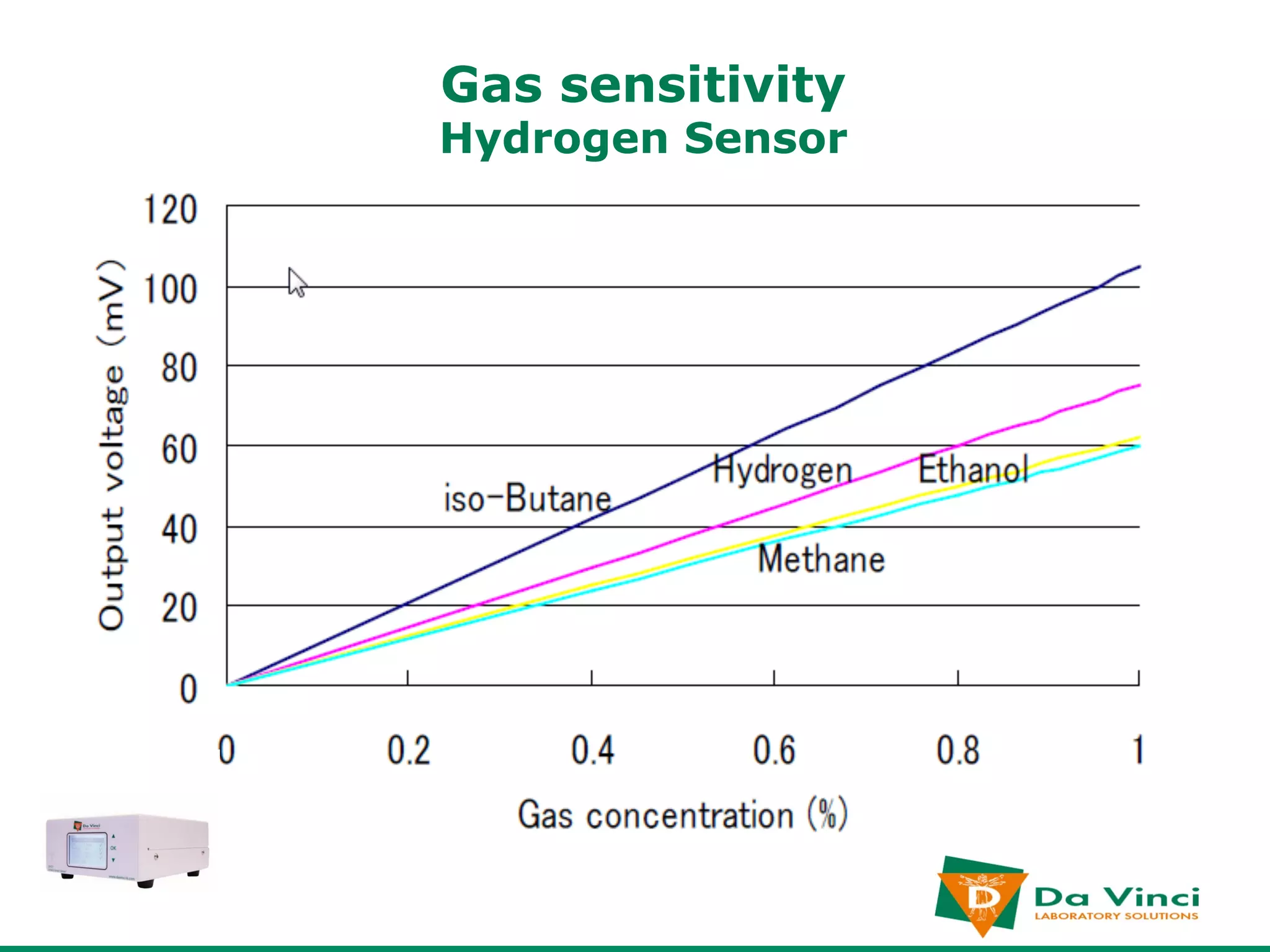

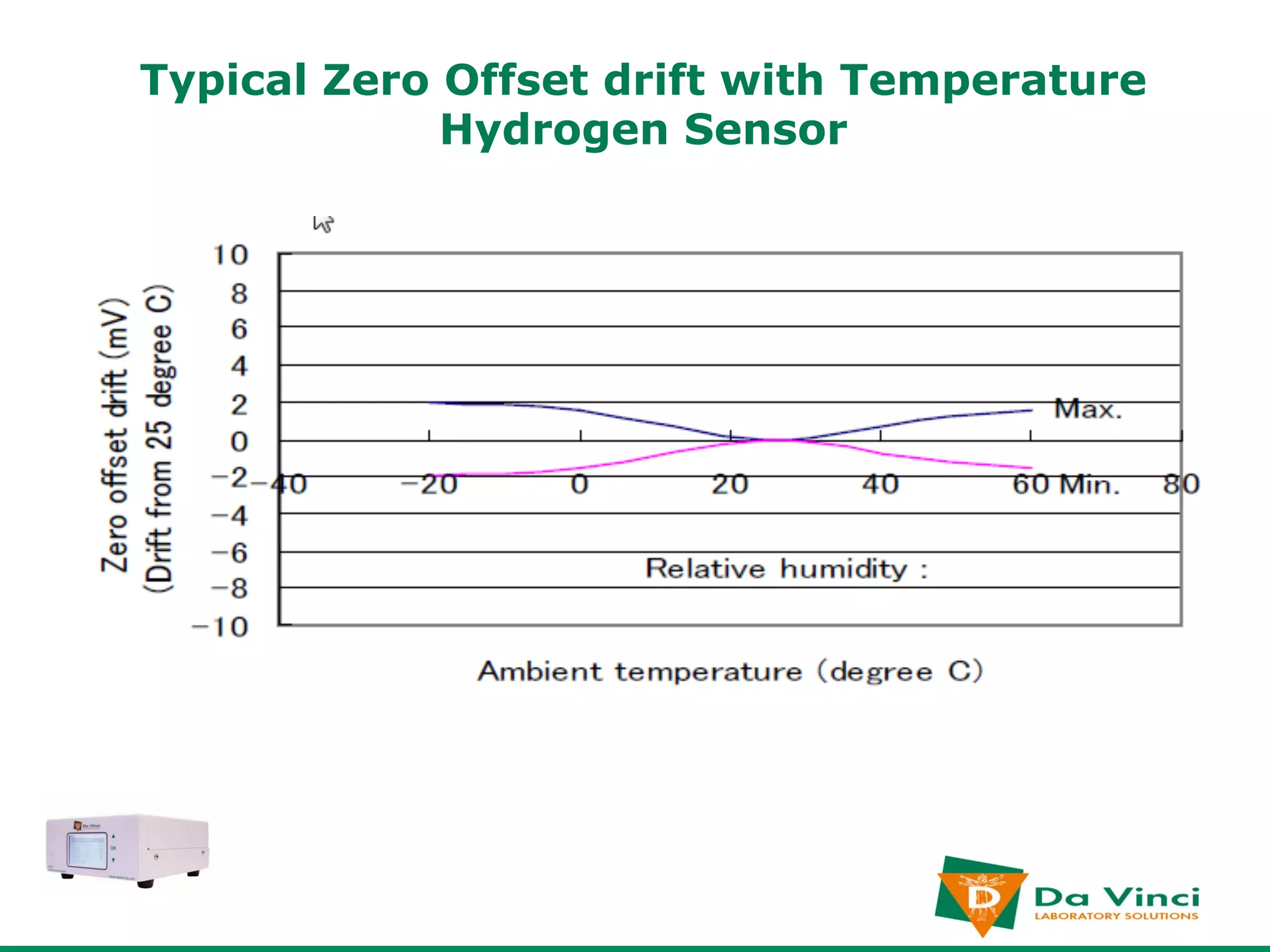

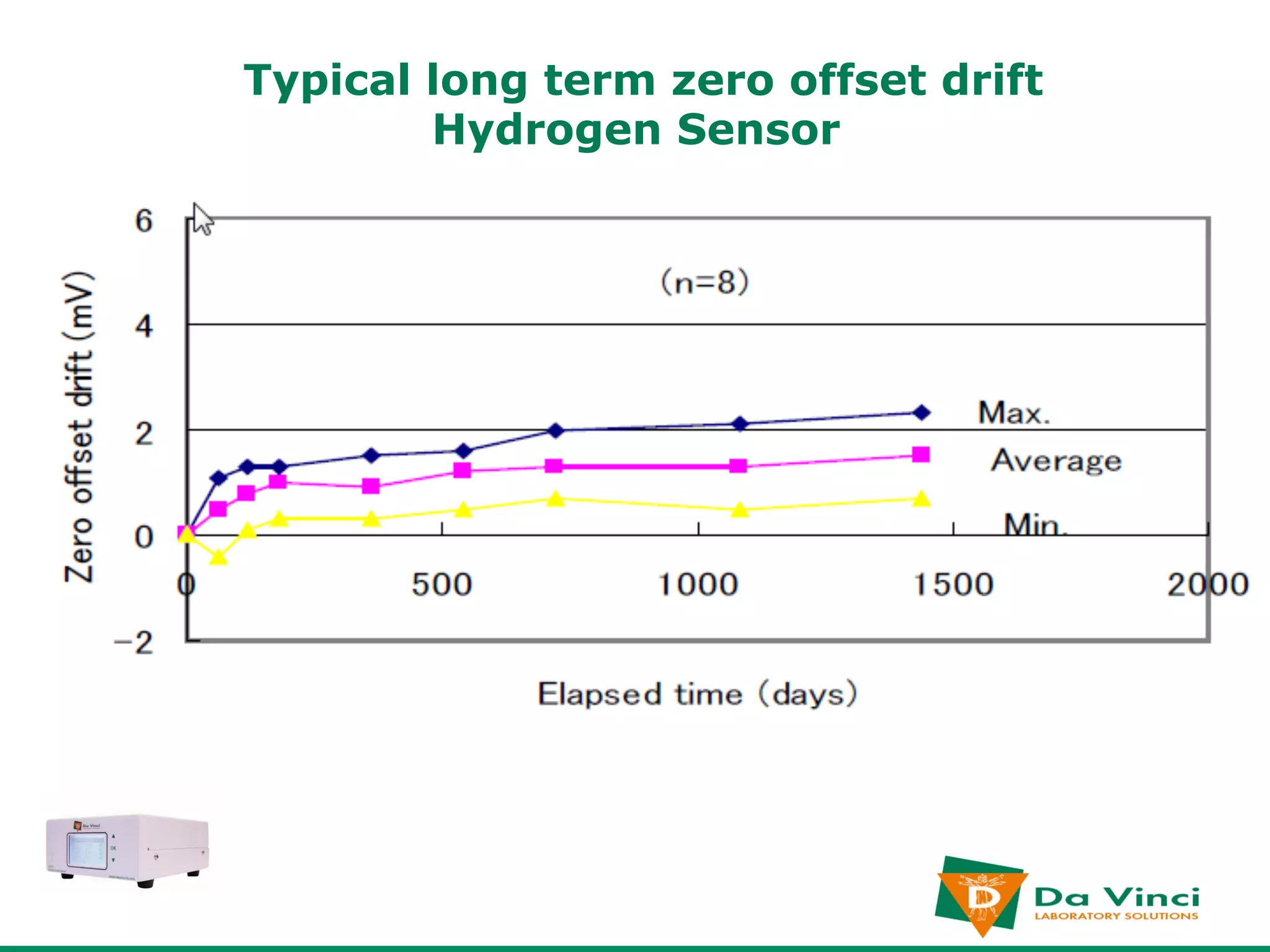

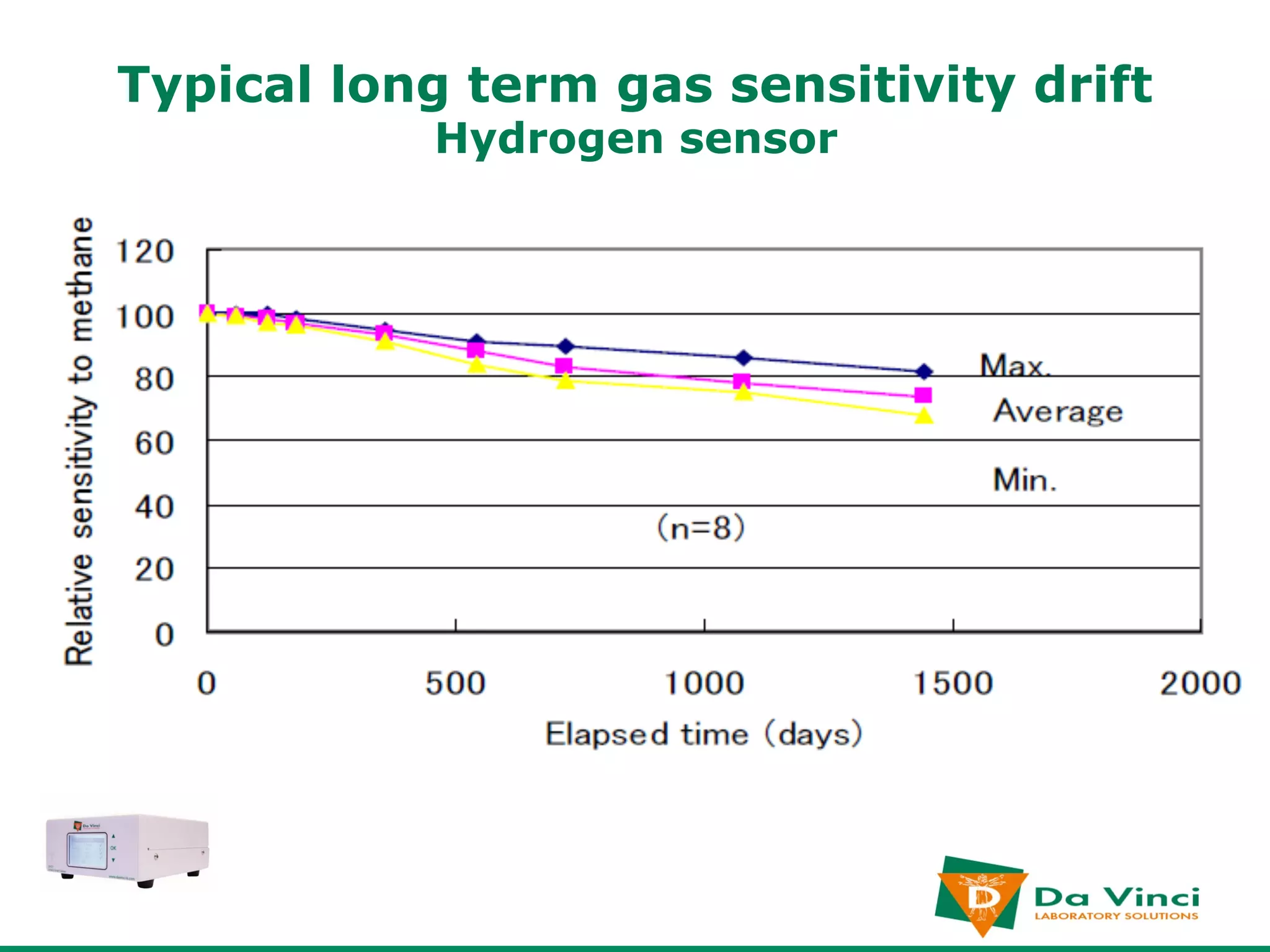

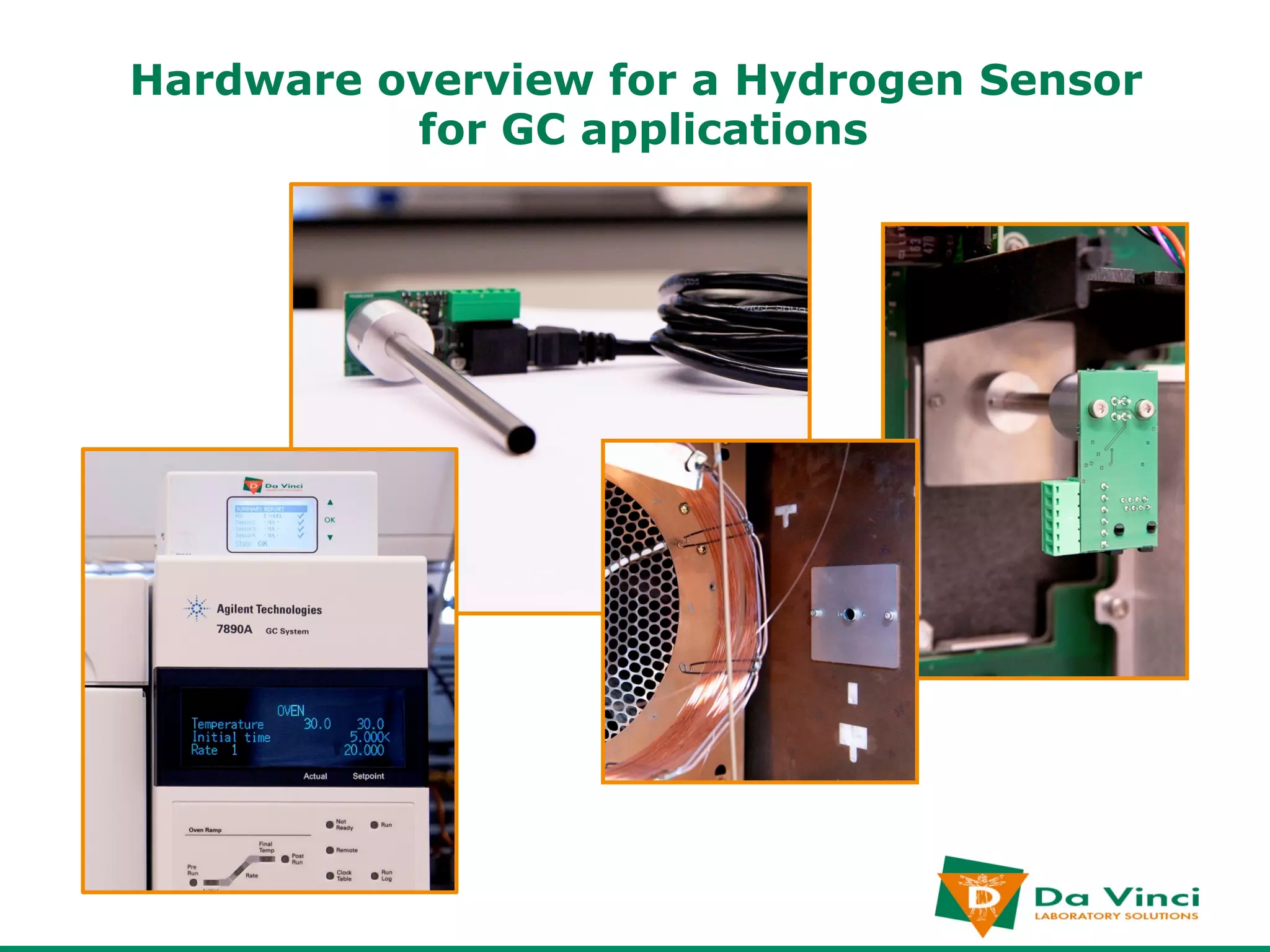

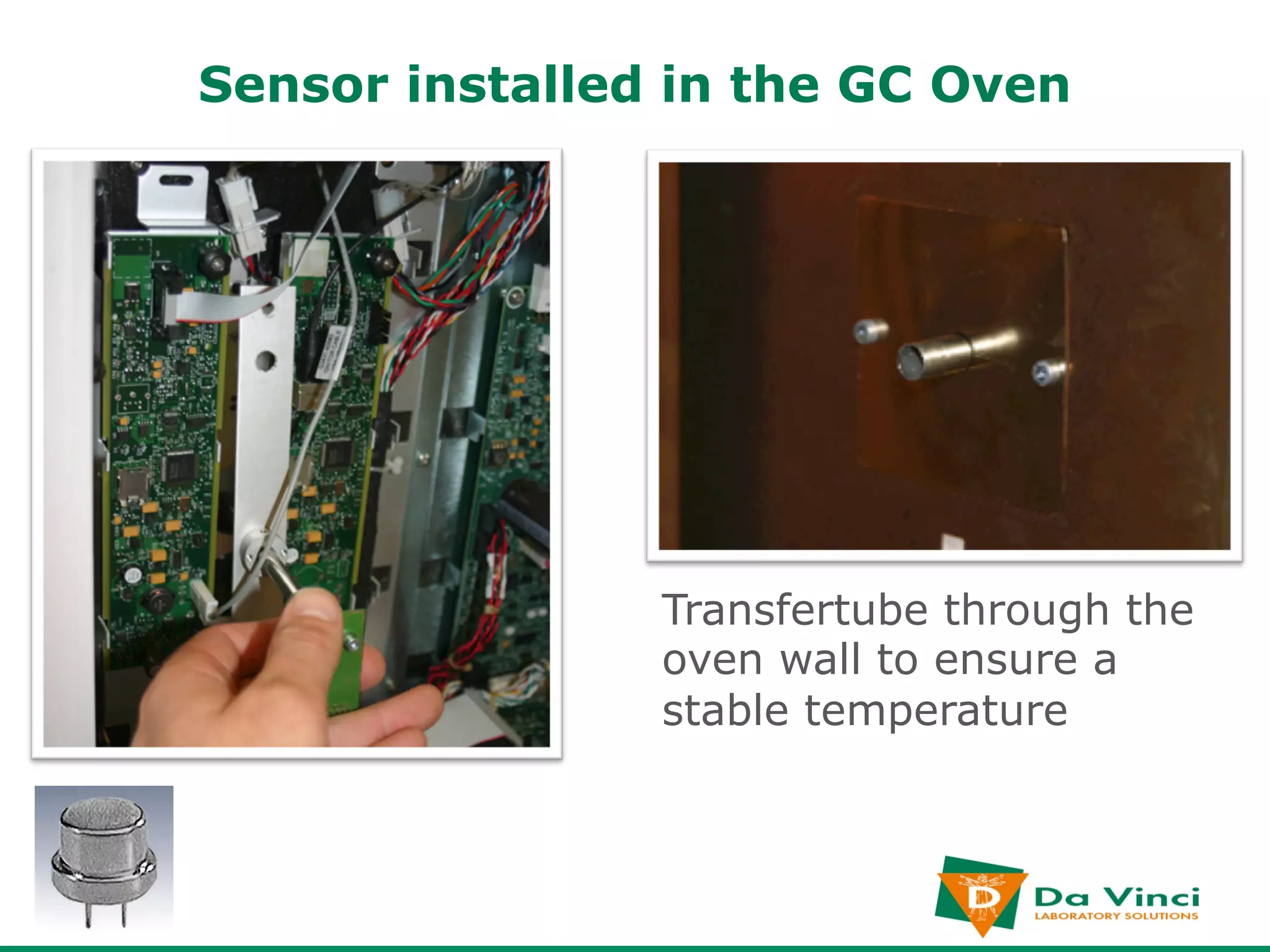

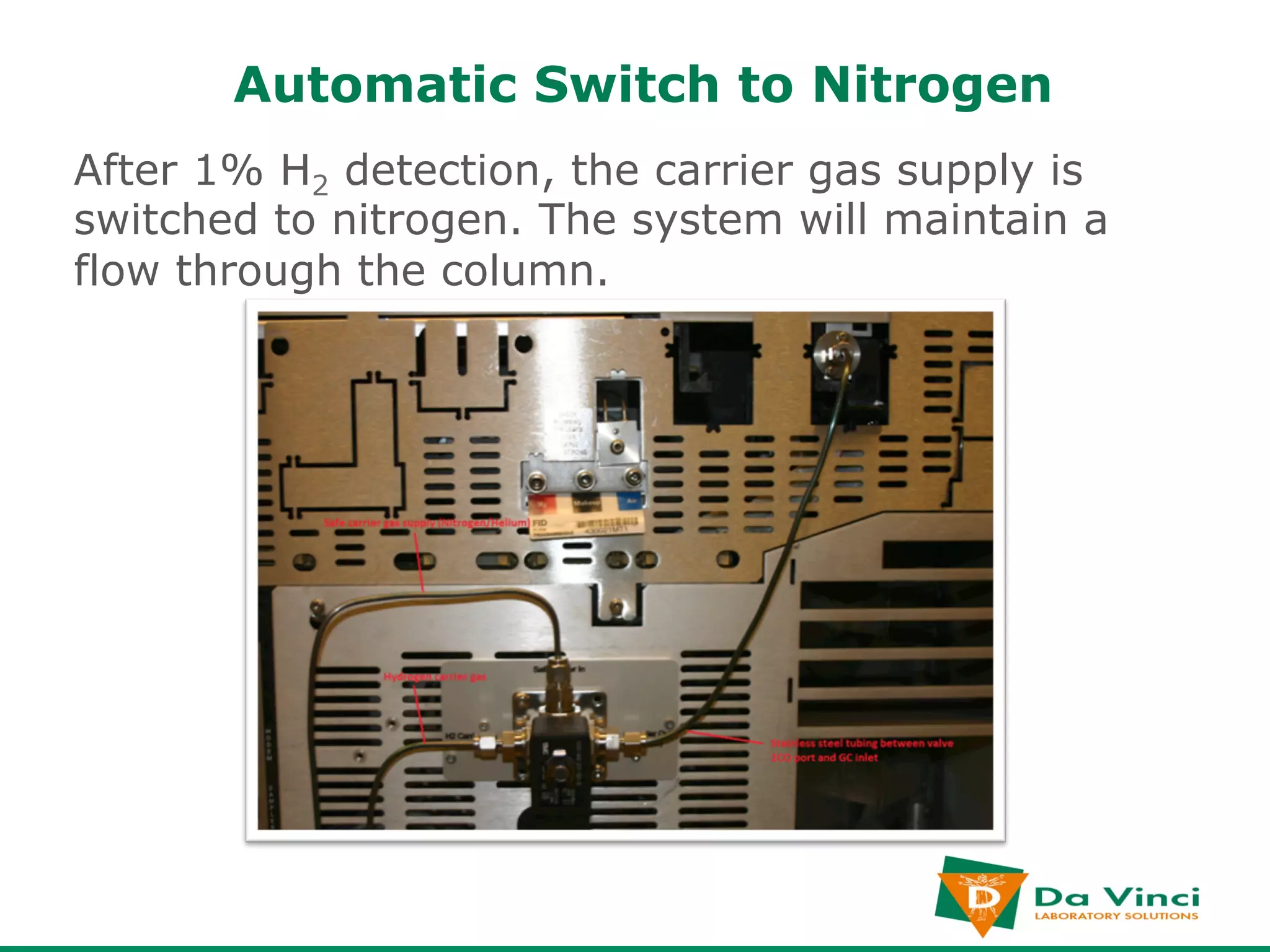

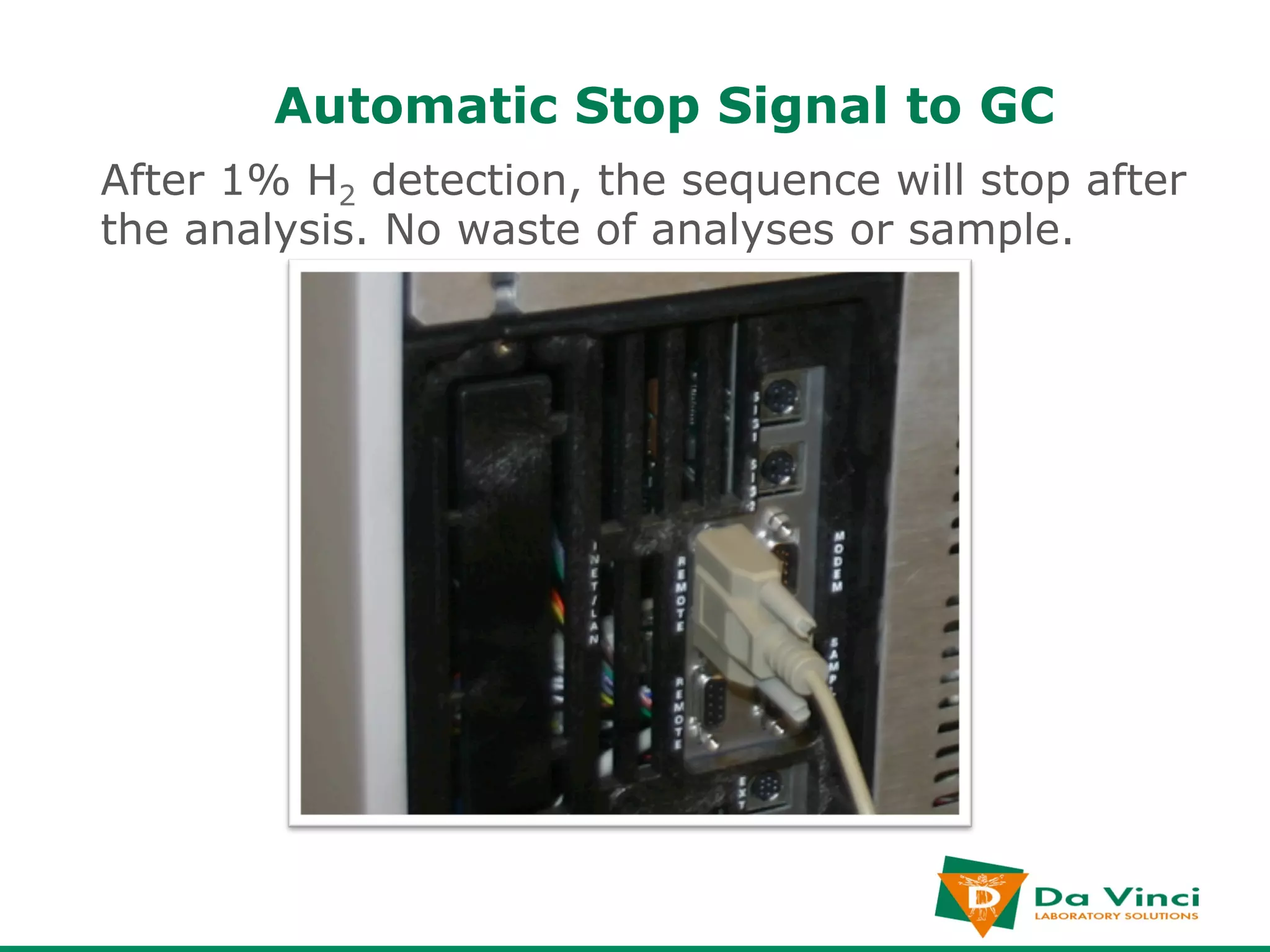

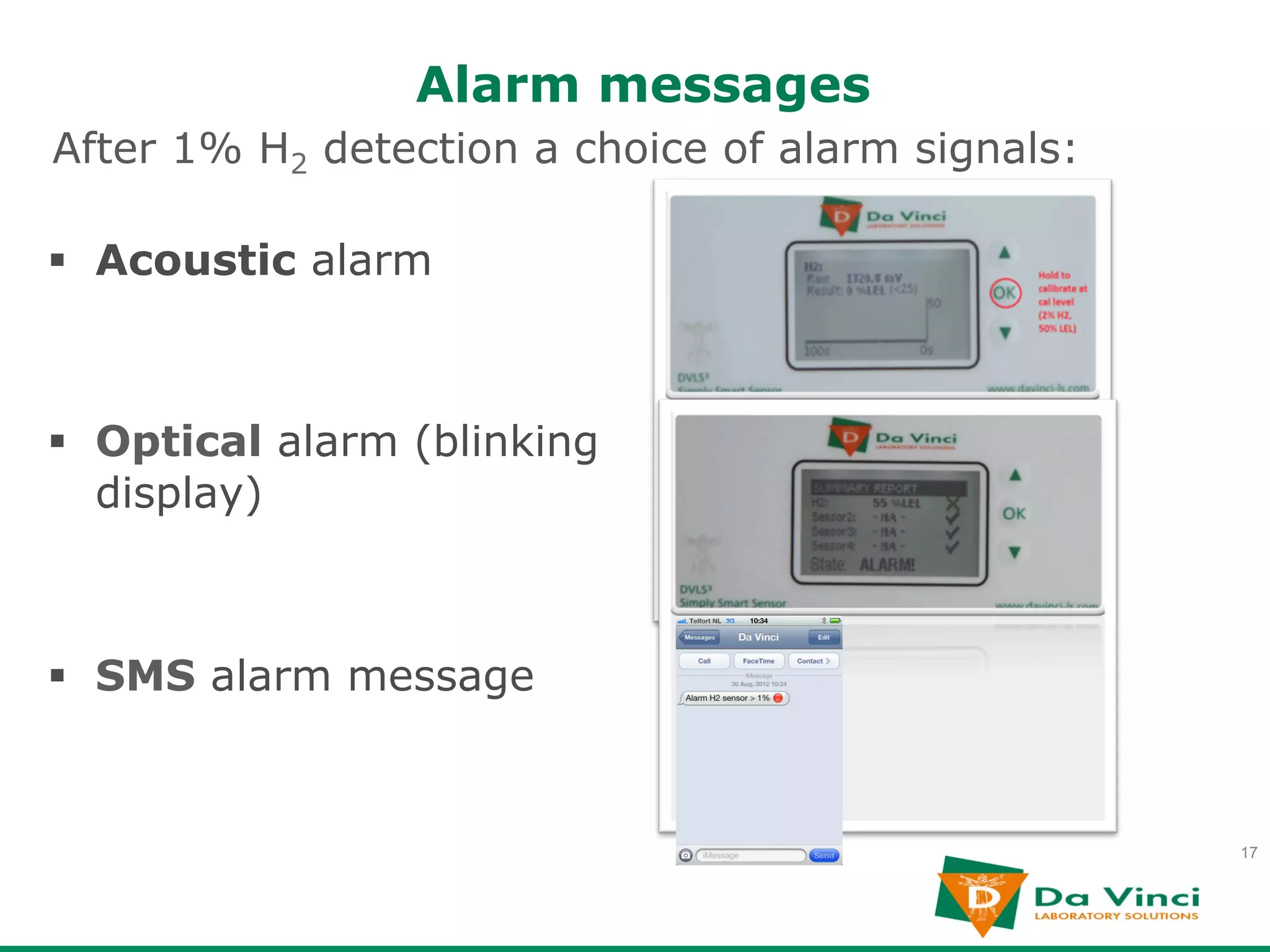

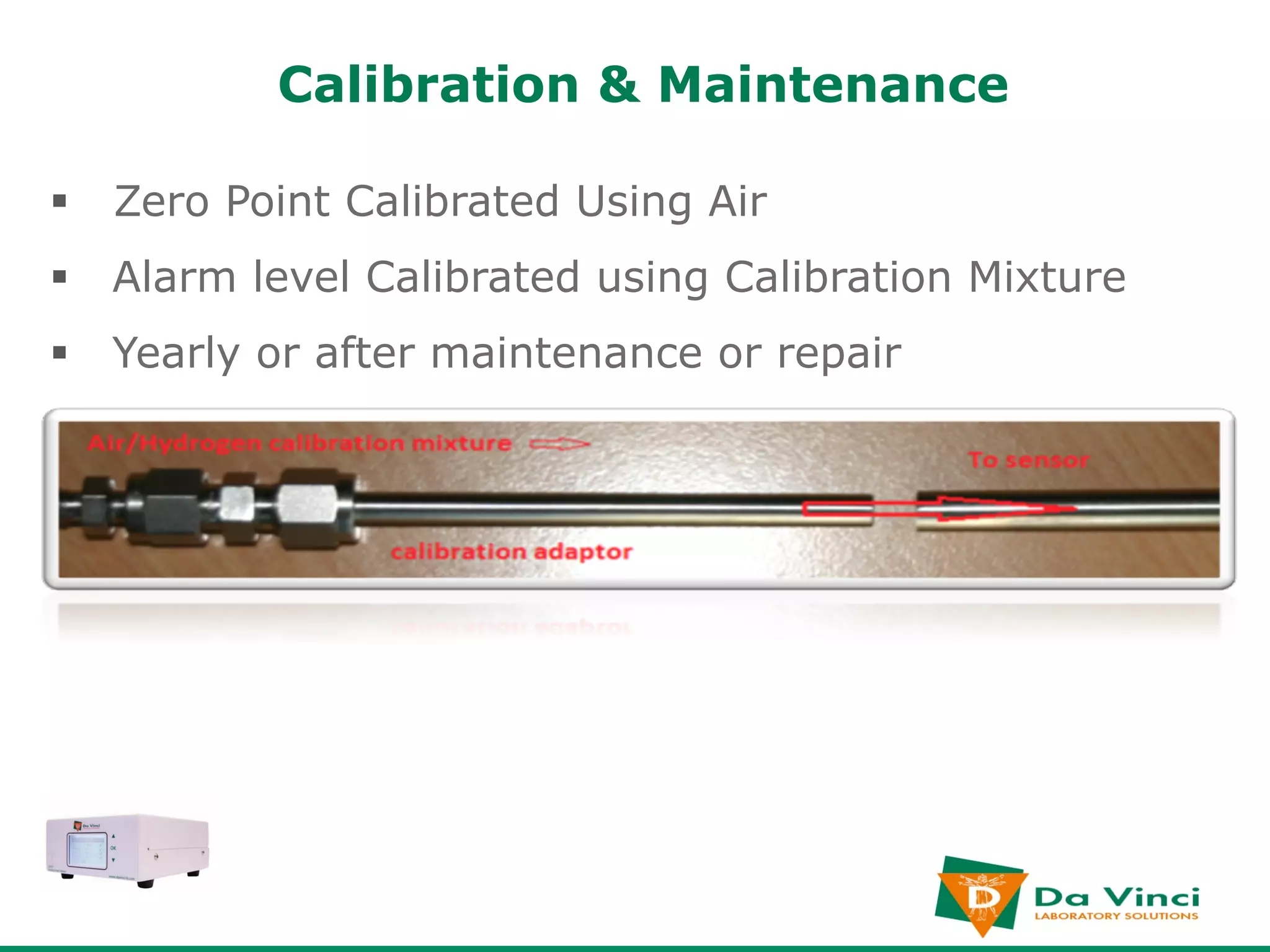

The document describes the DVLS3 Simply Smart Hydrogen Sensor, which is designed for use in chromatographic systems with hydrogen as a carrier gas due to its fast analysis, high efficiency, prolonged column life, and cost-effectiveness. It outlines safety measures for handling hydrogen gas, including monitoring usage, automatic shutoff mechanisms, and alarm systems. Additionally, the sensor features a catalytic combustion principle for detecting hydrogen, offers calibration and maintenance guidelines, and ensures long-term stability and sensitivity in various operating conditions.