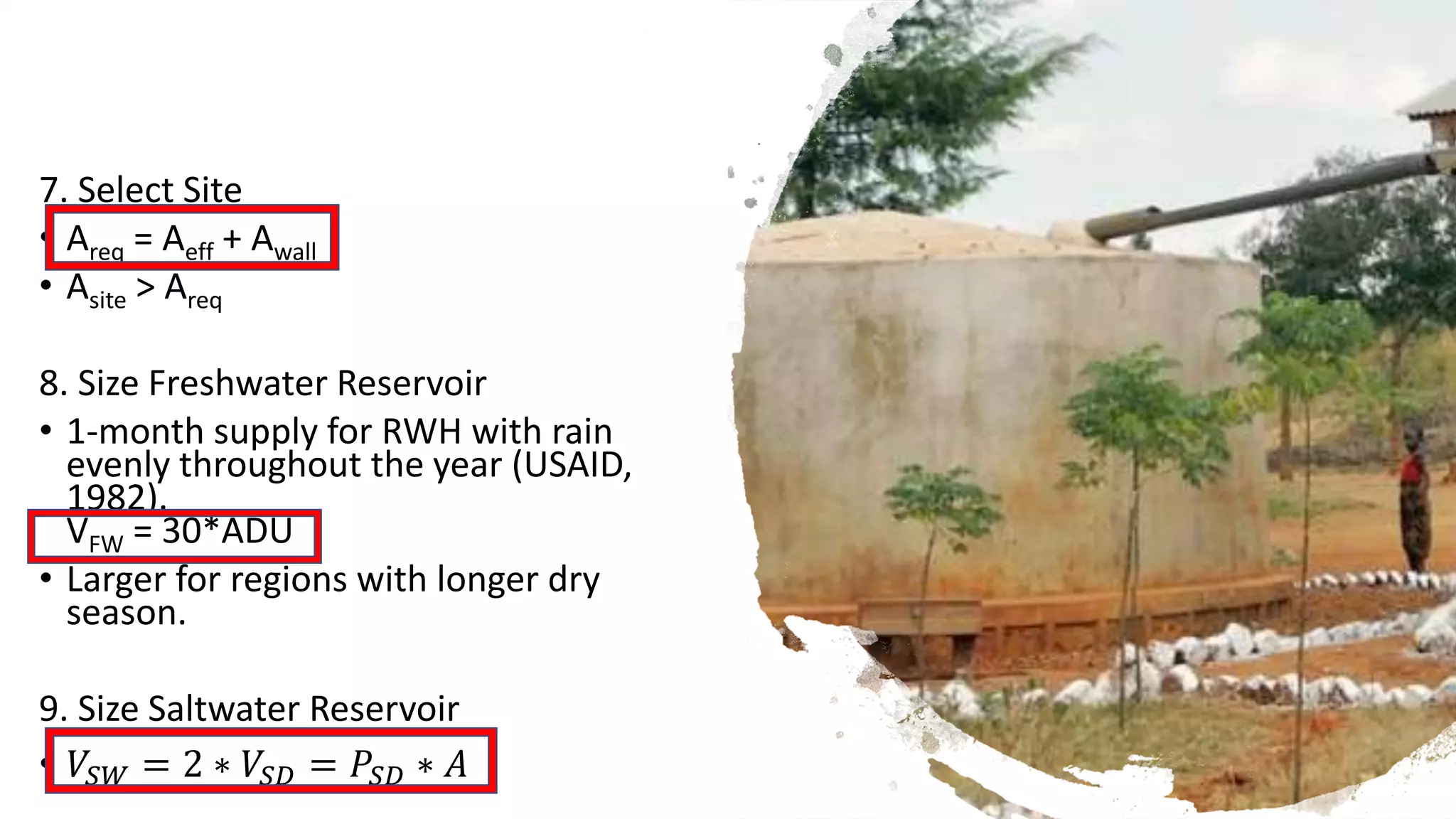

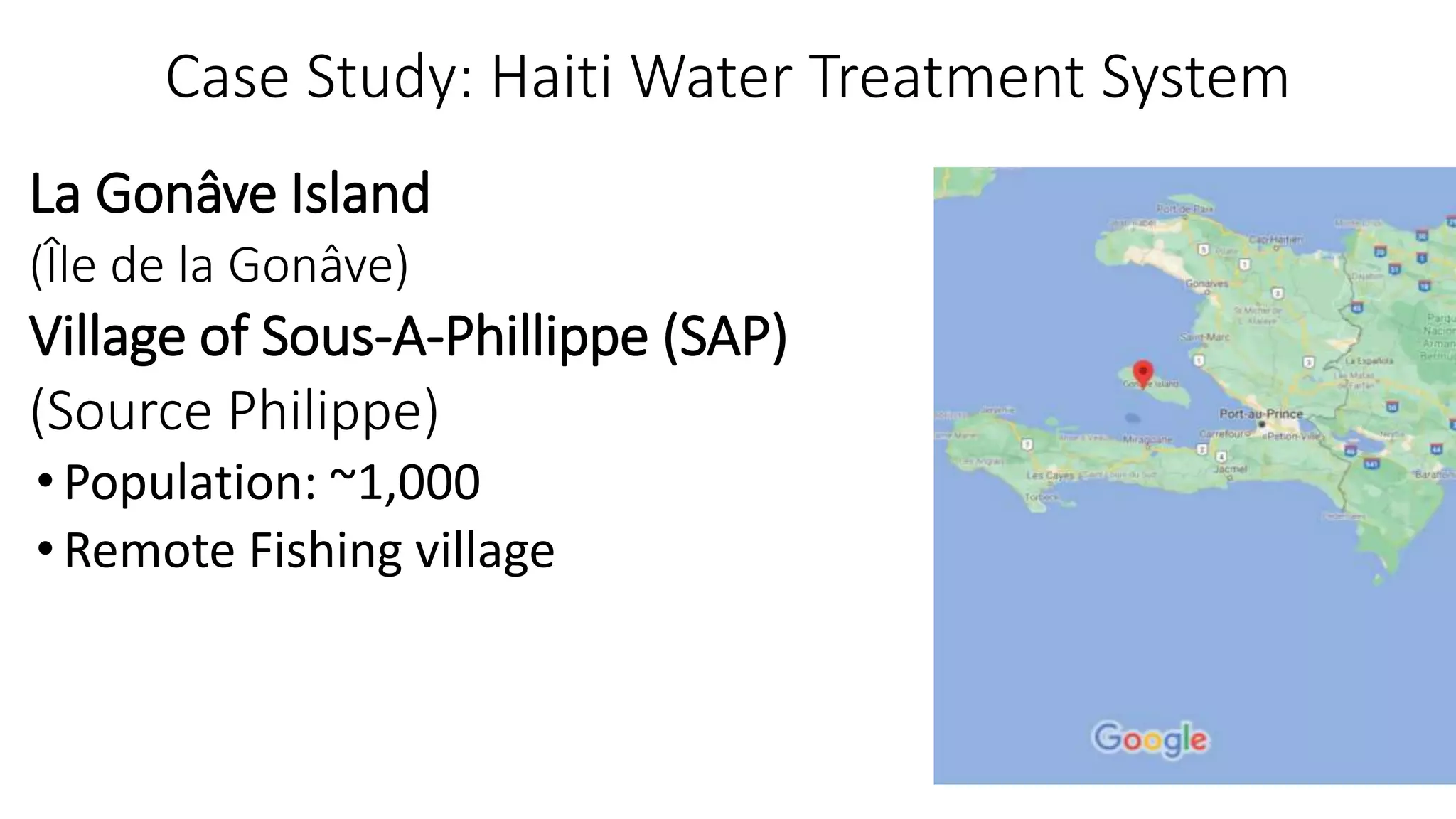

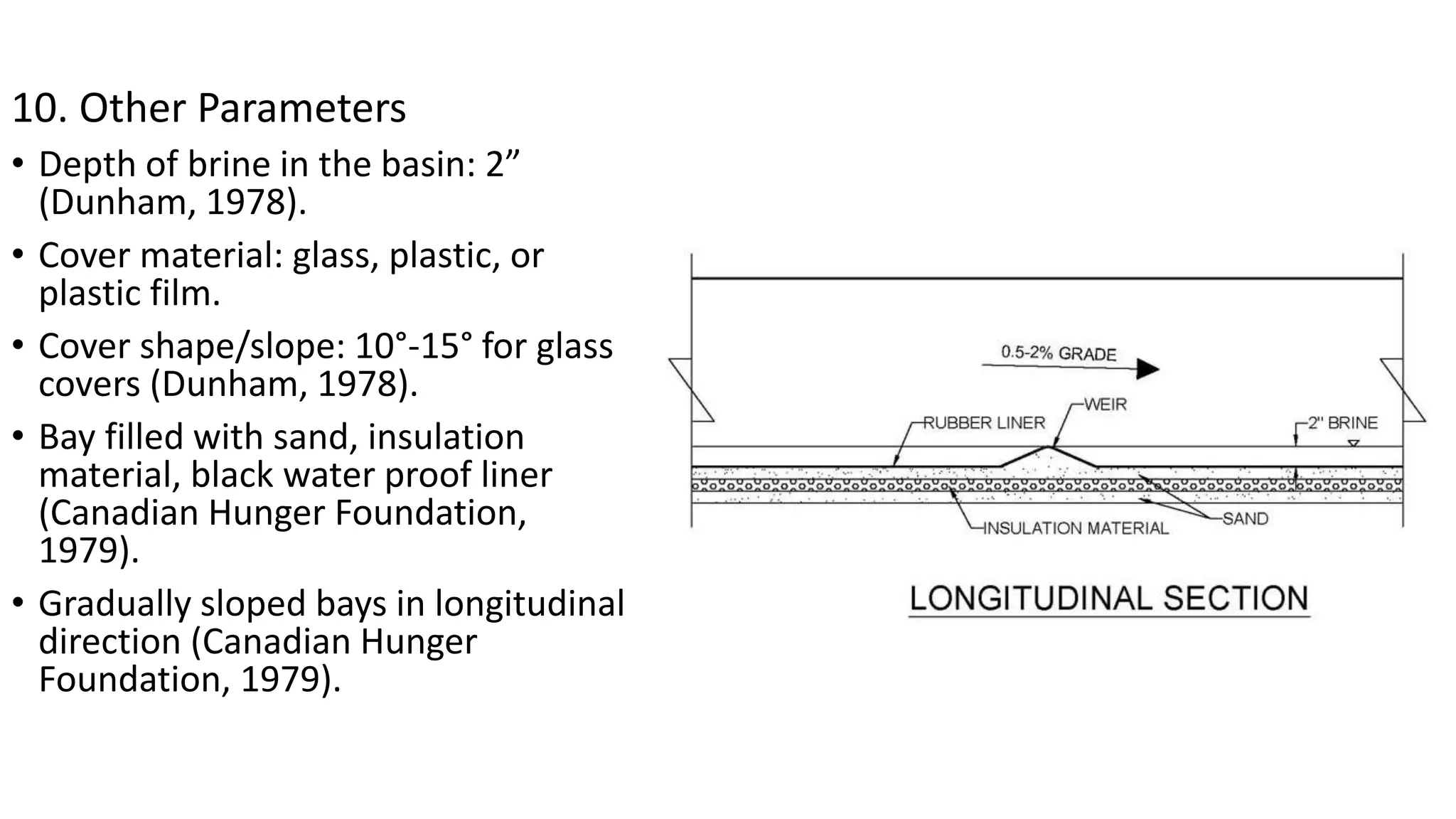

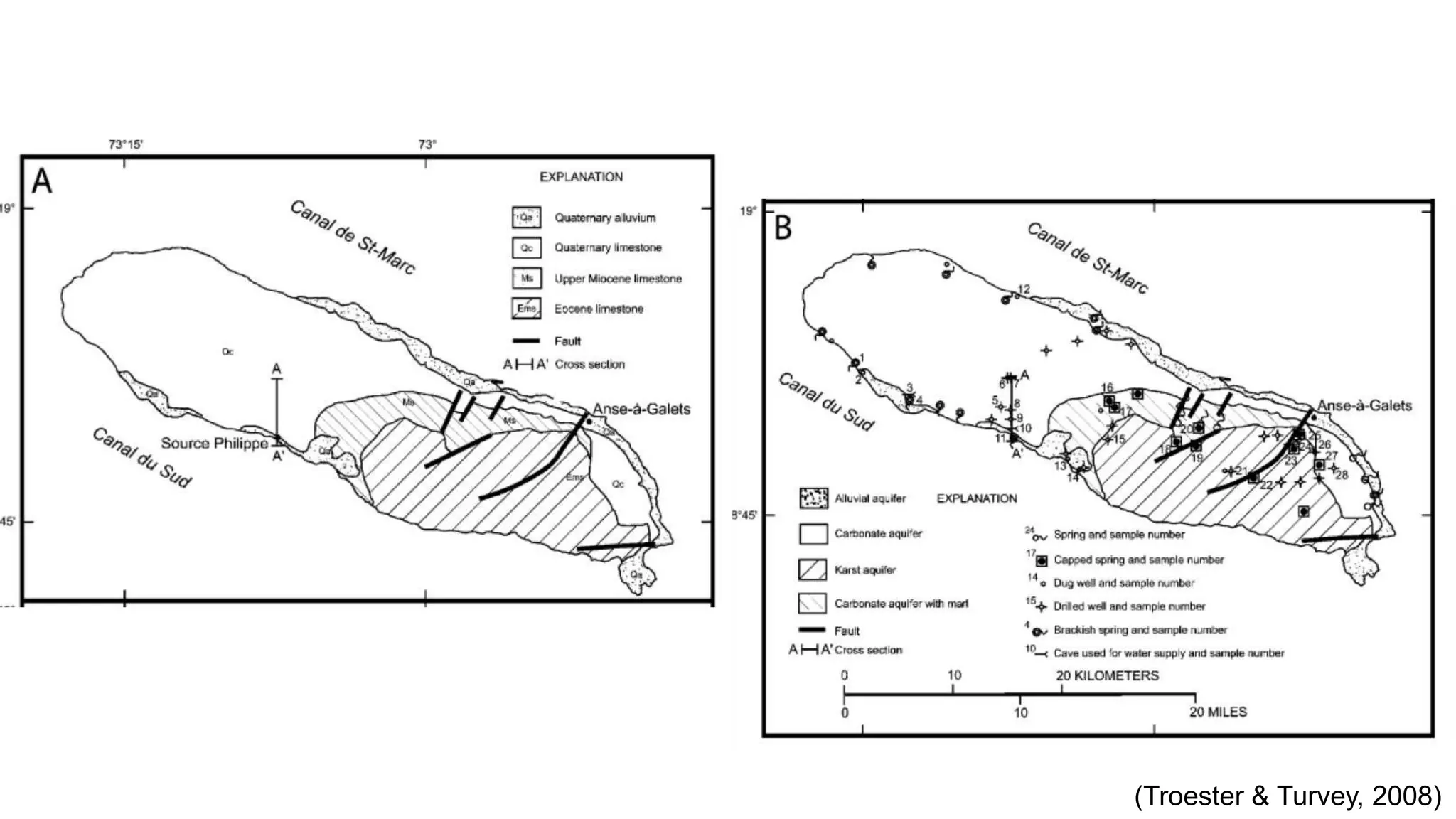

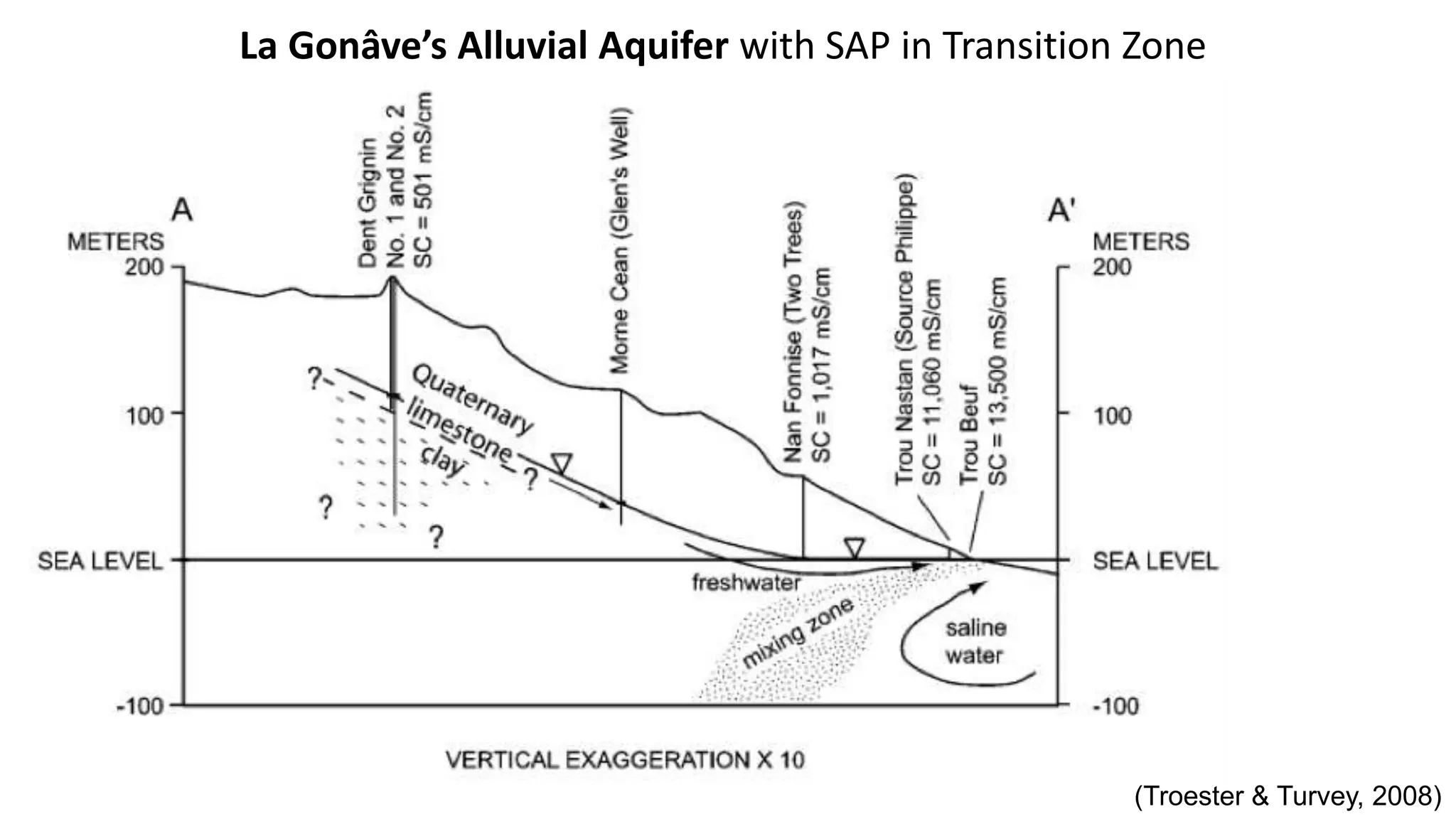

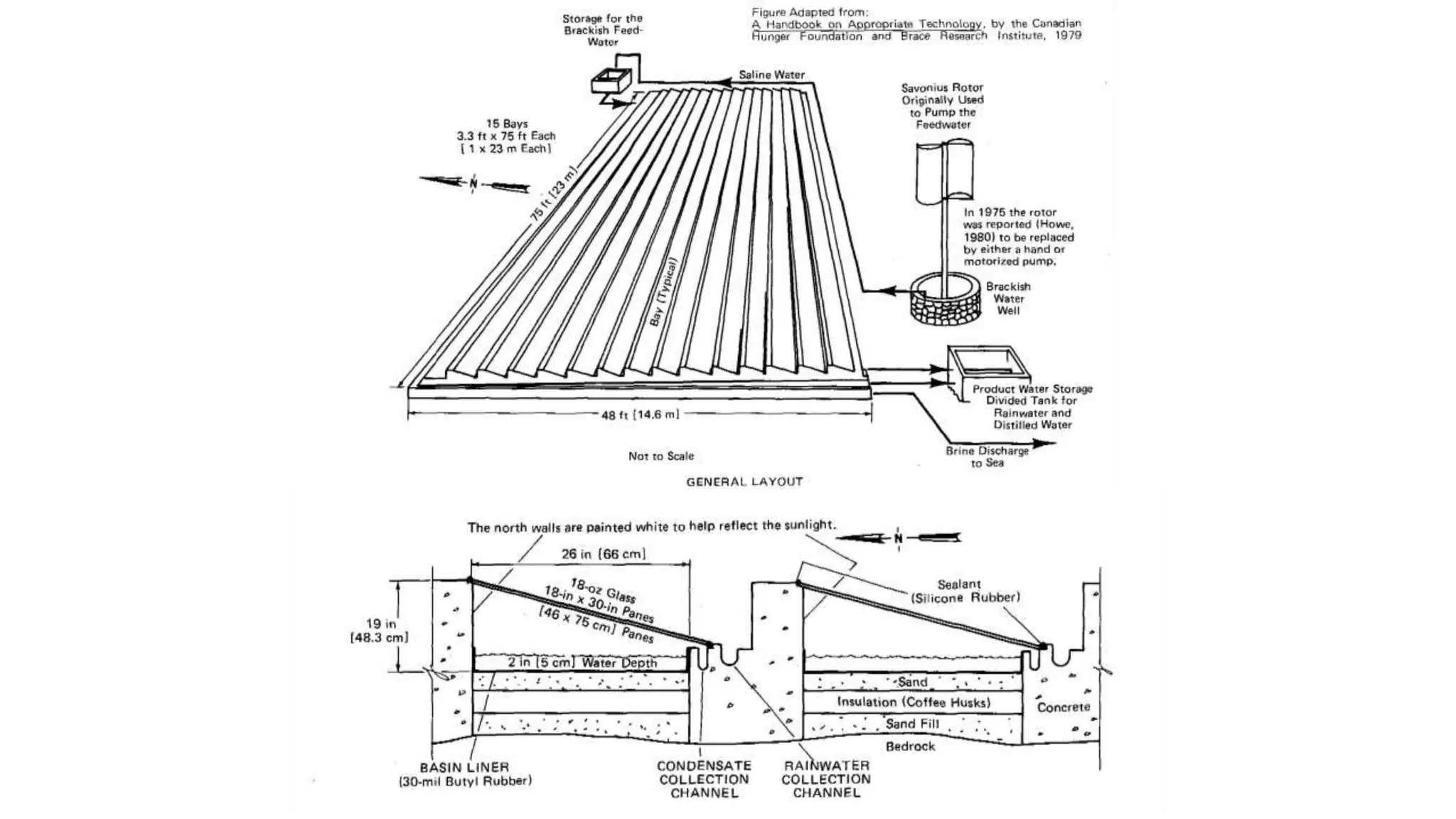

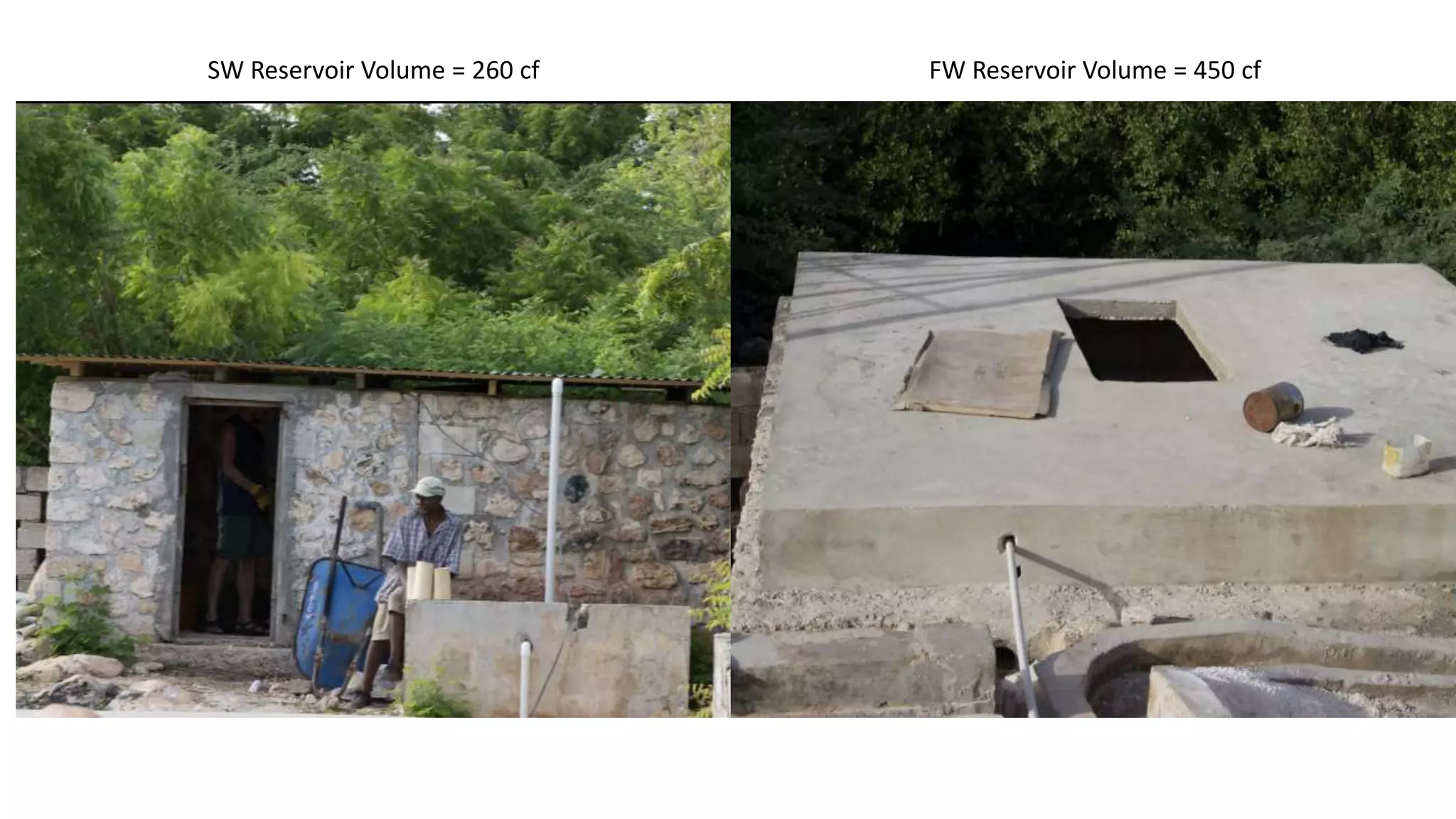

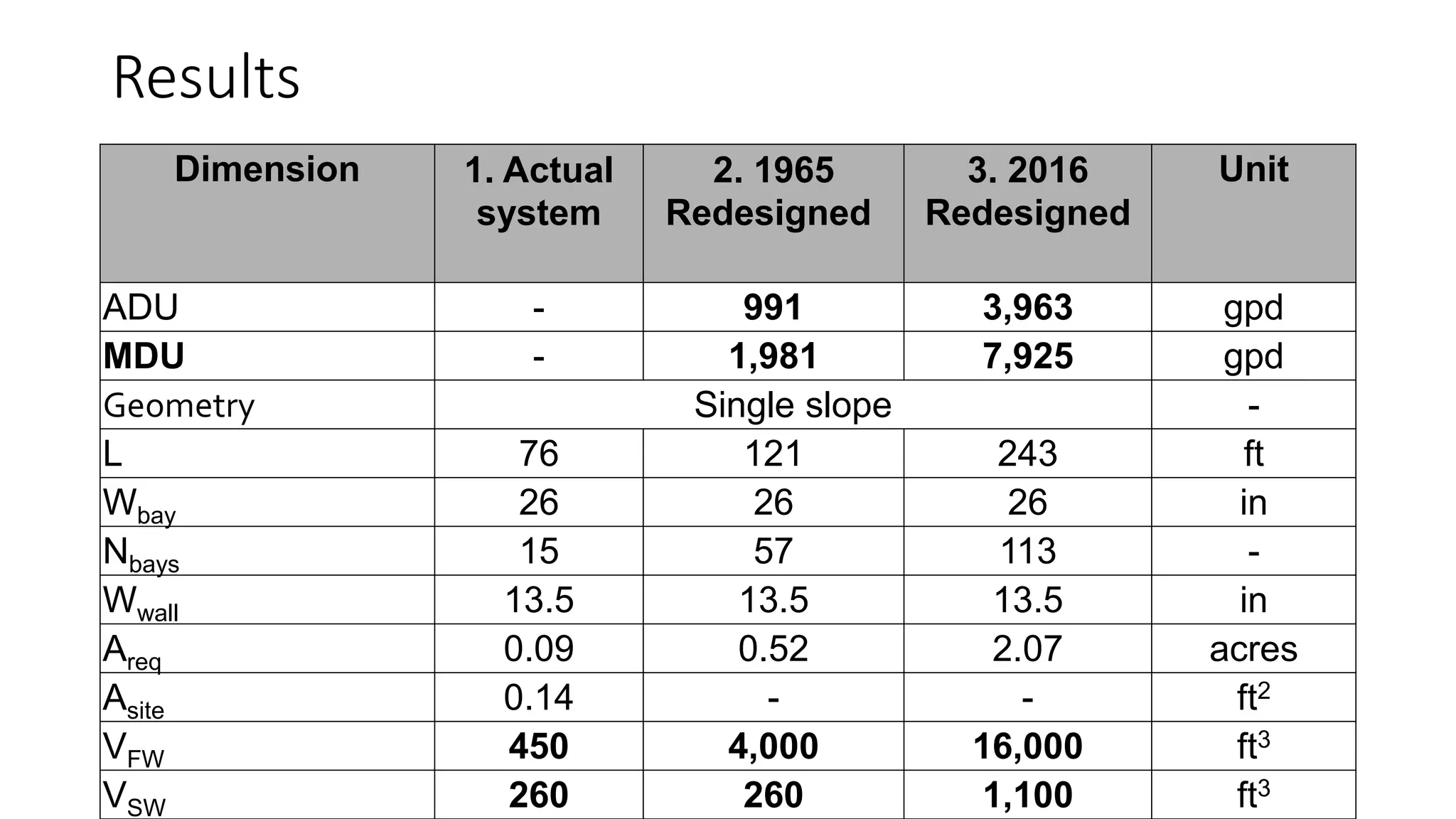

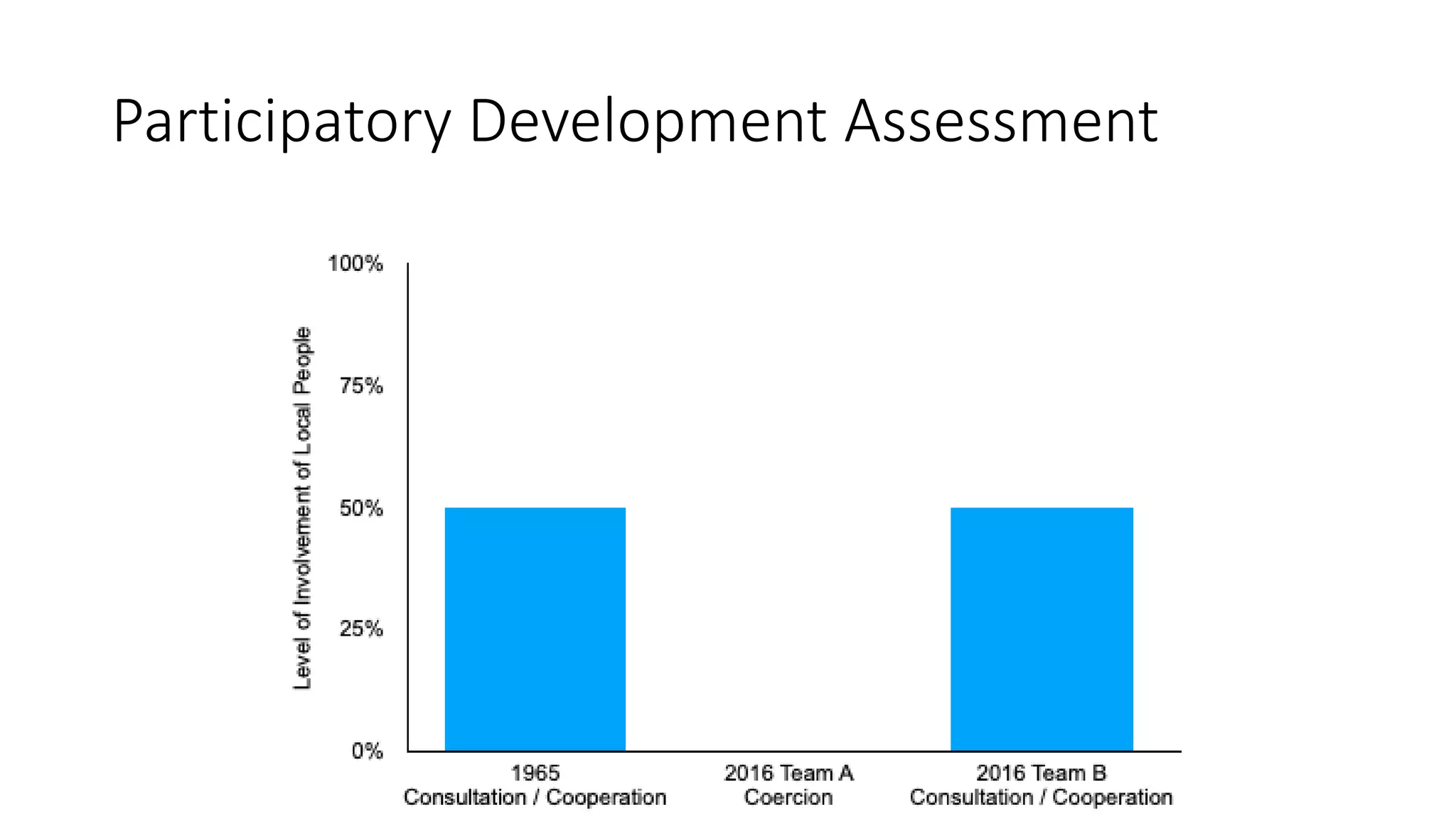

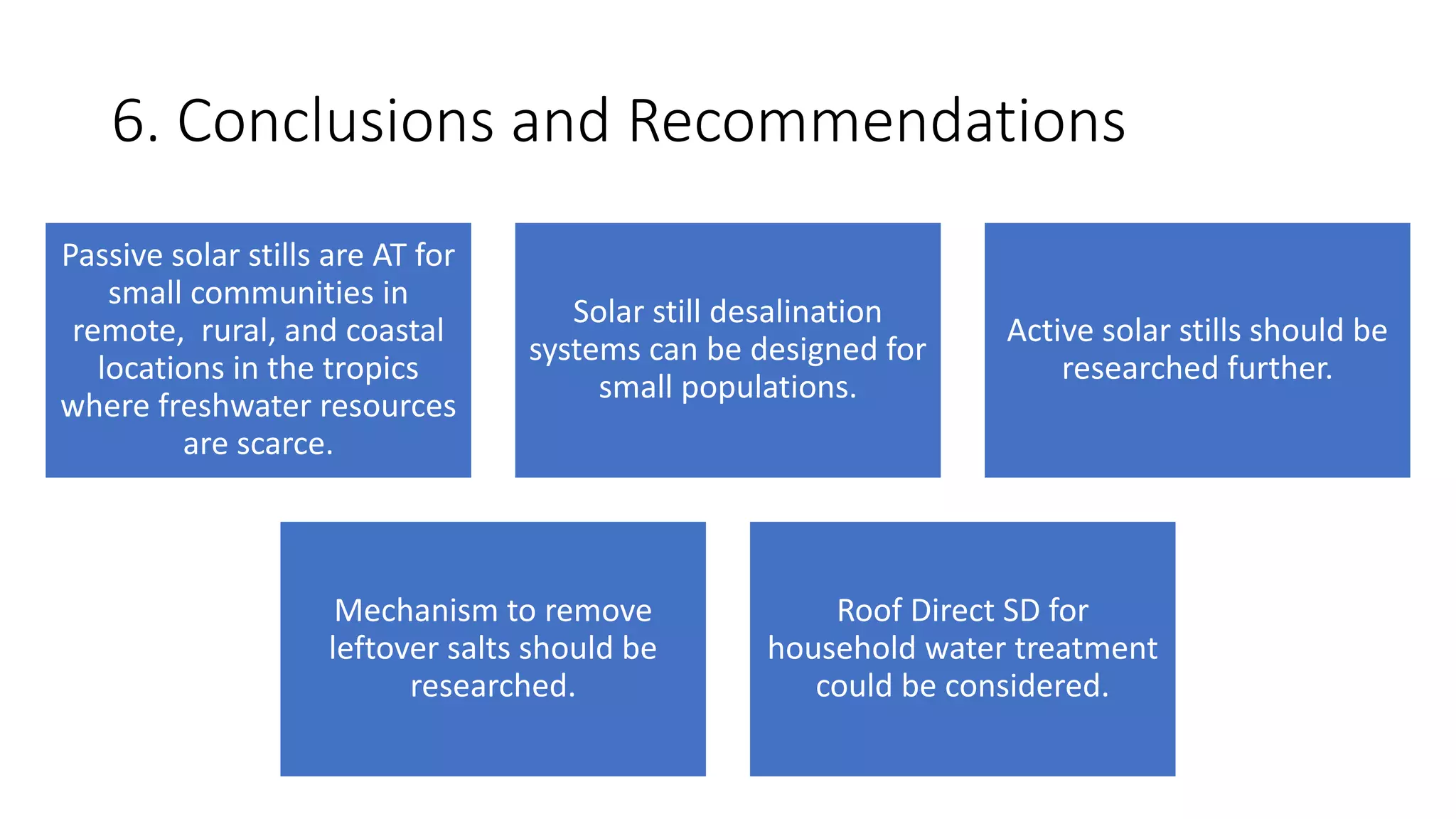

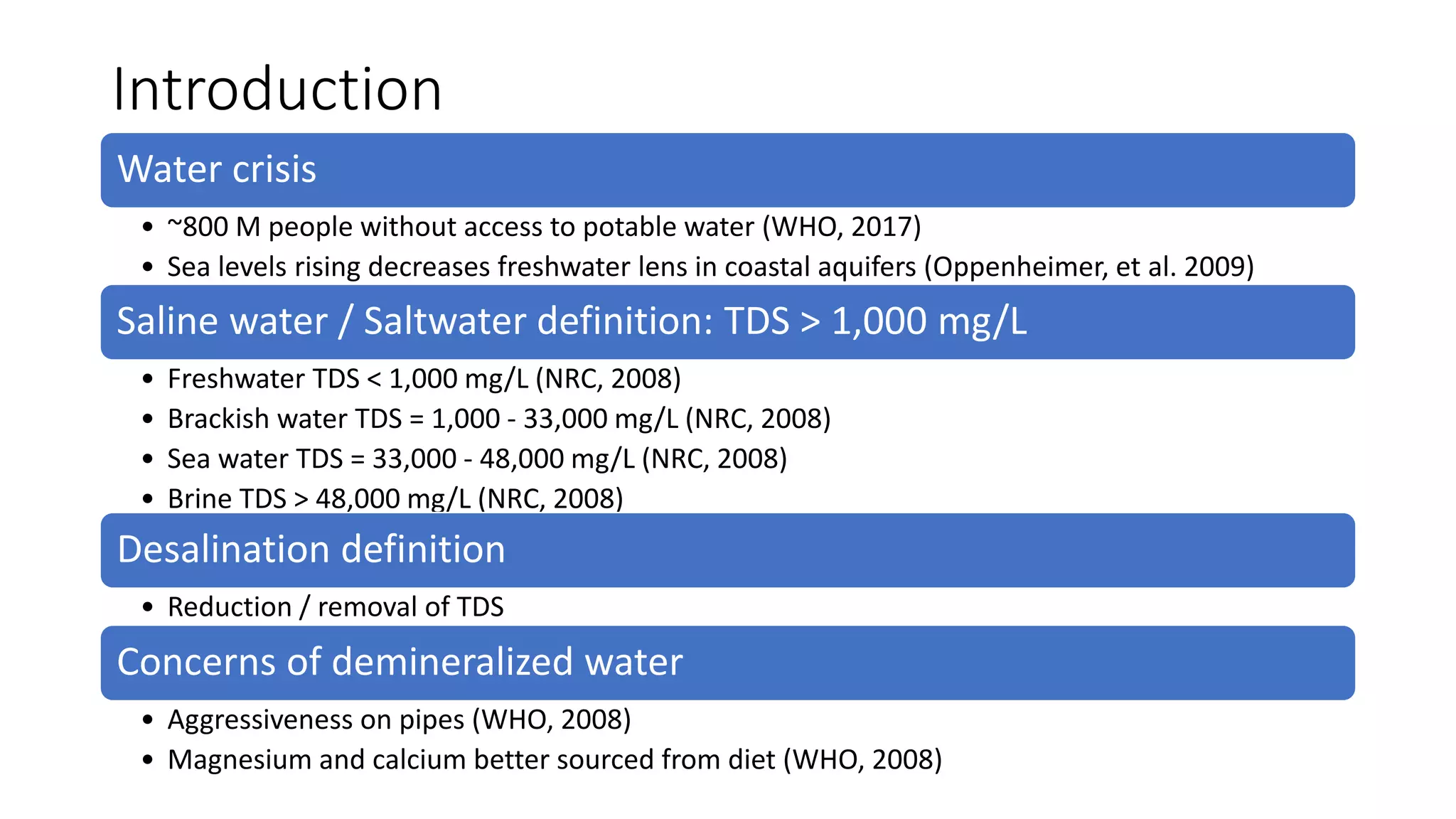

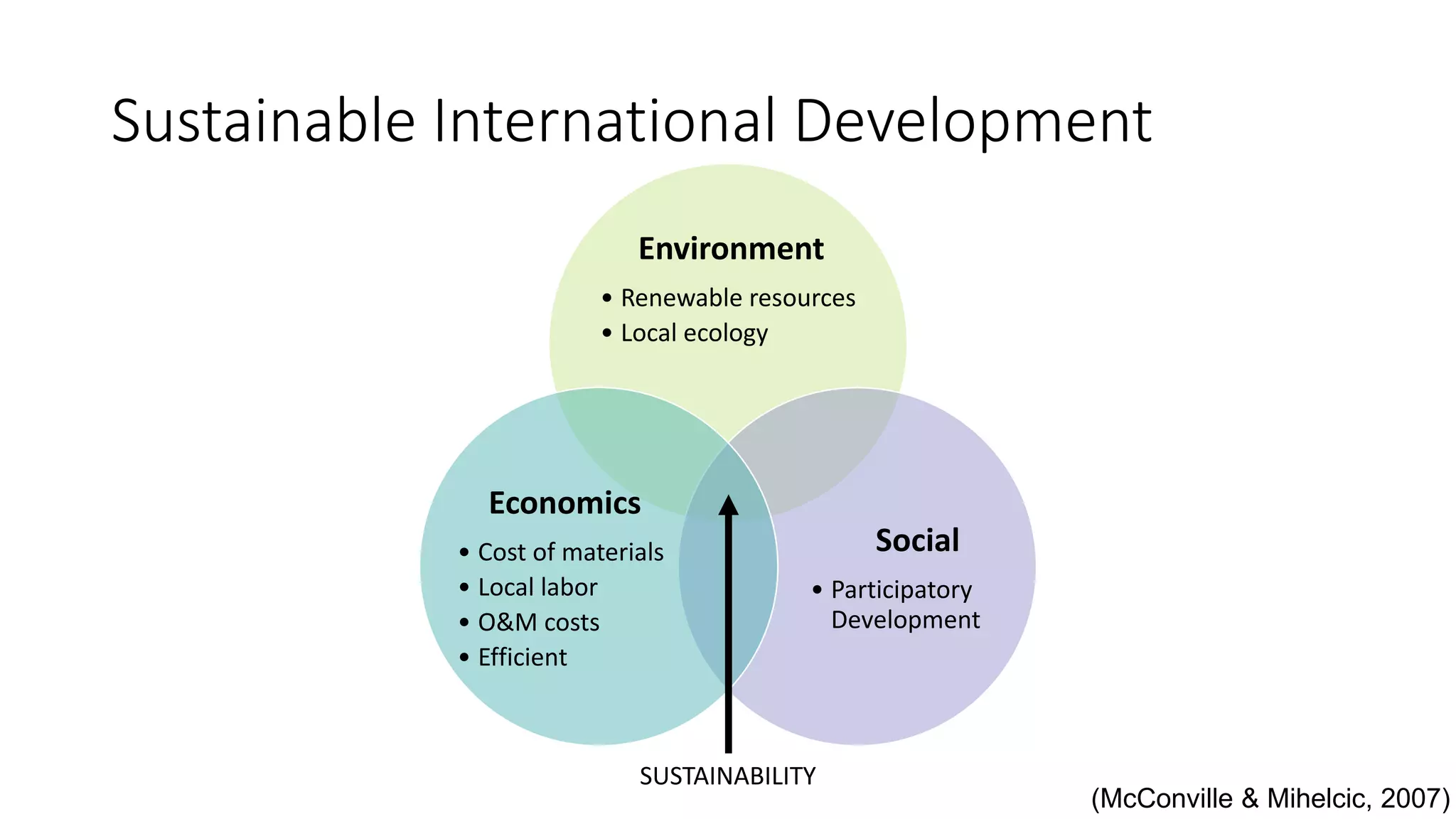

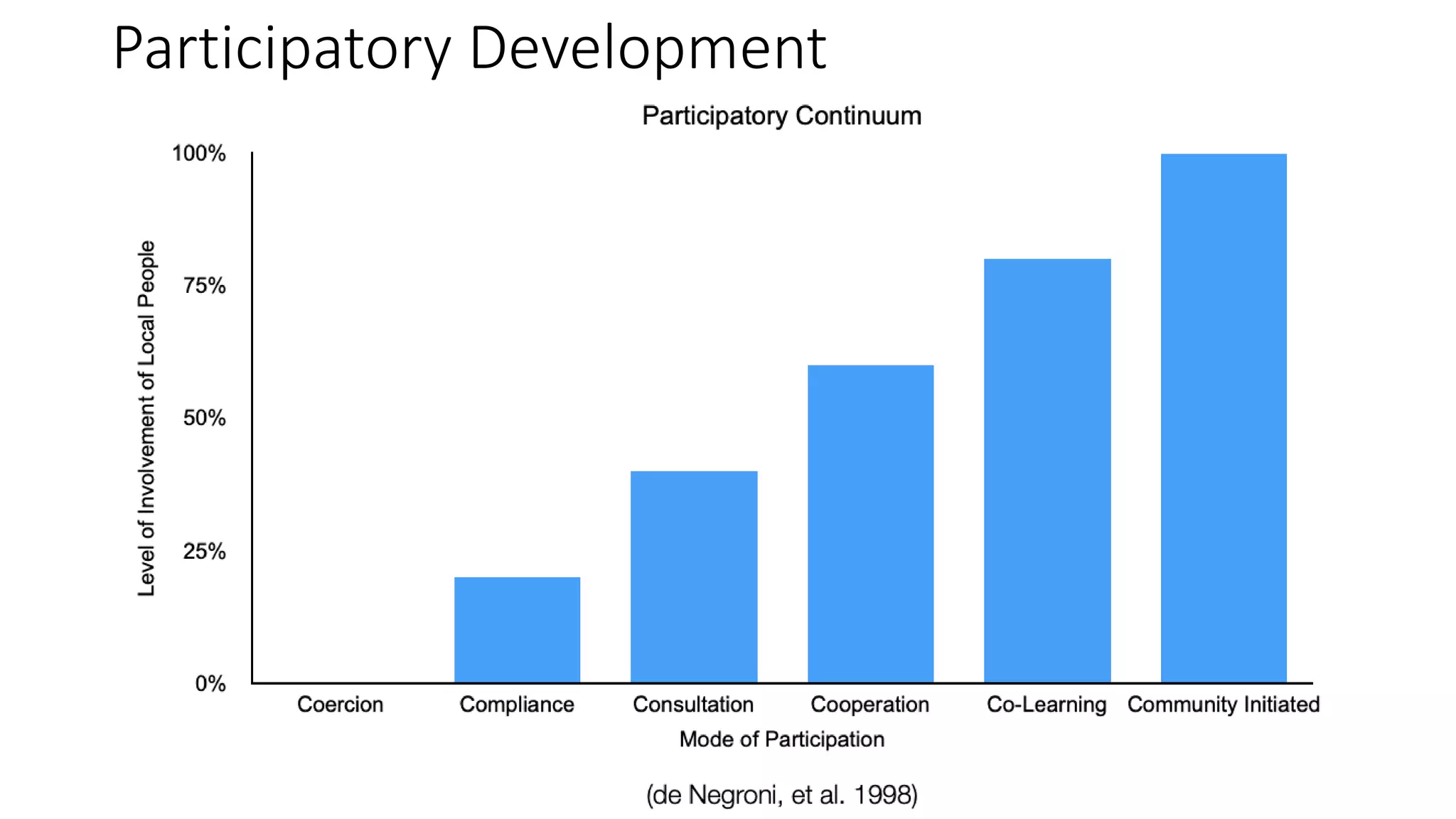

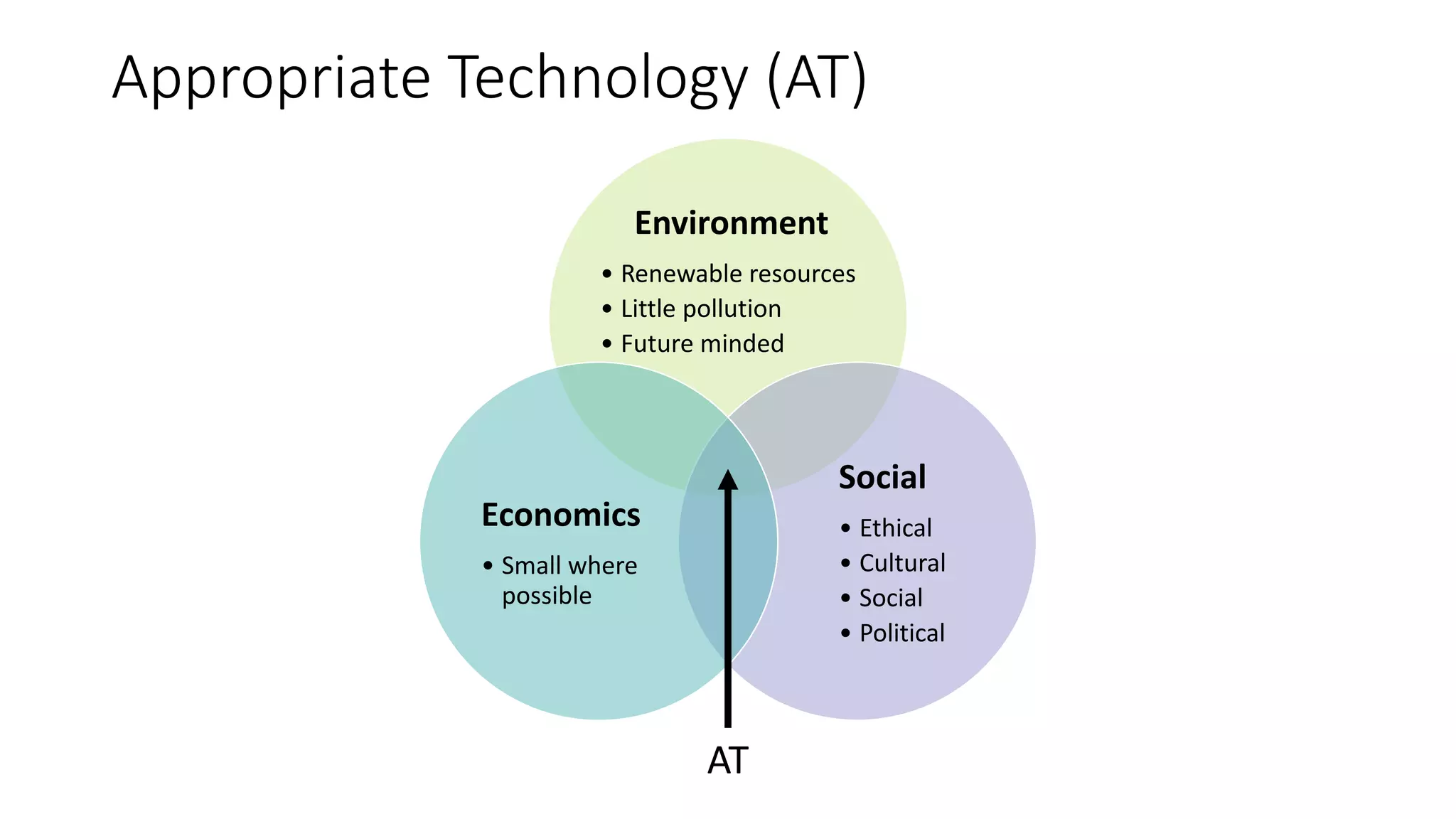

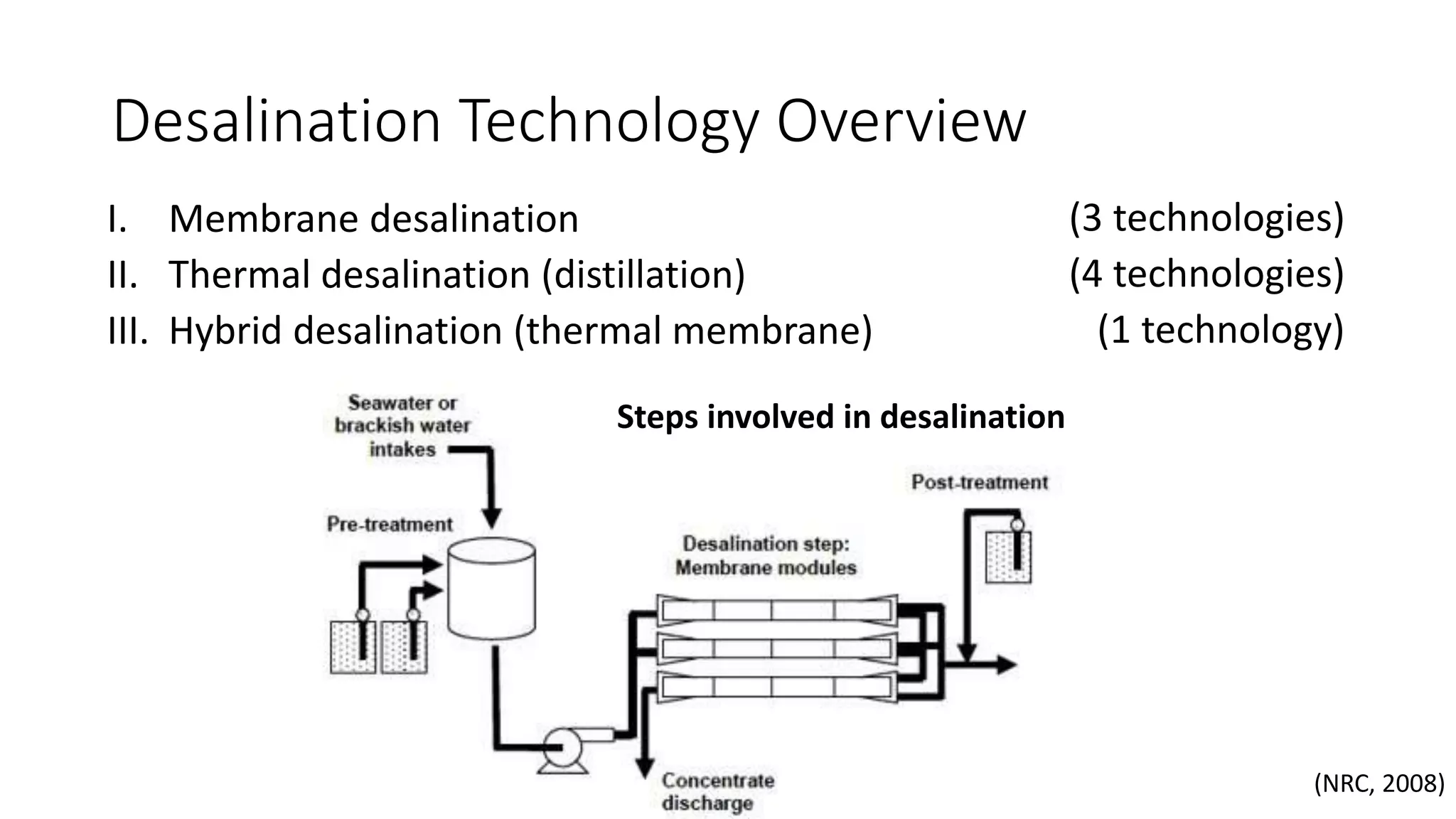

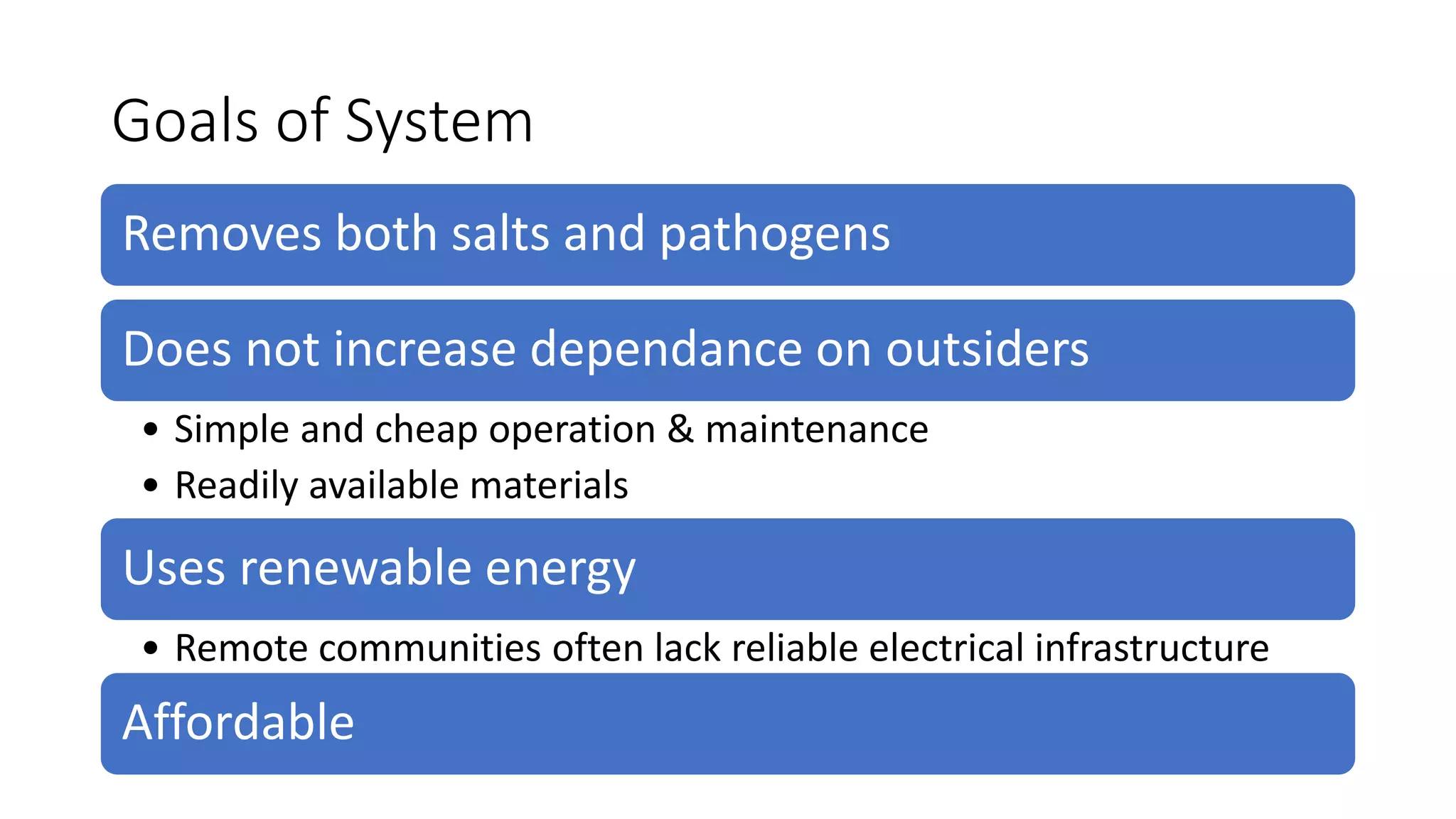

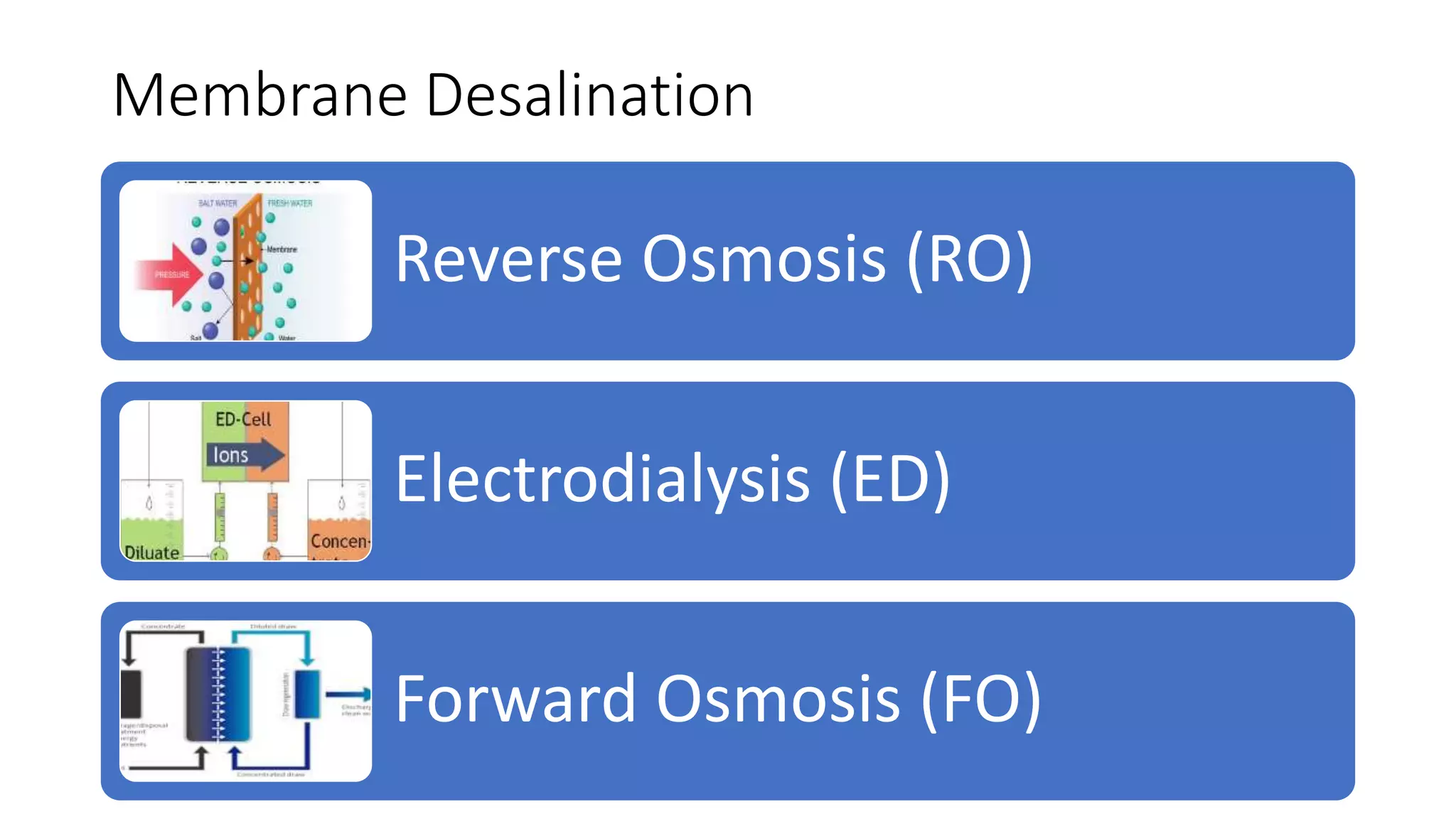

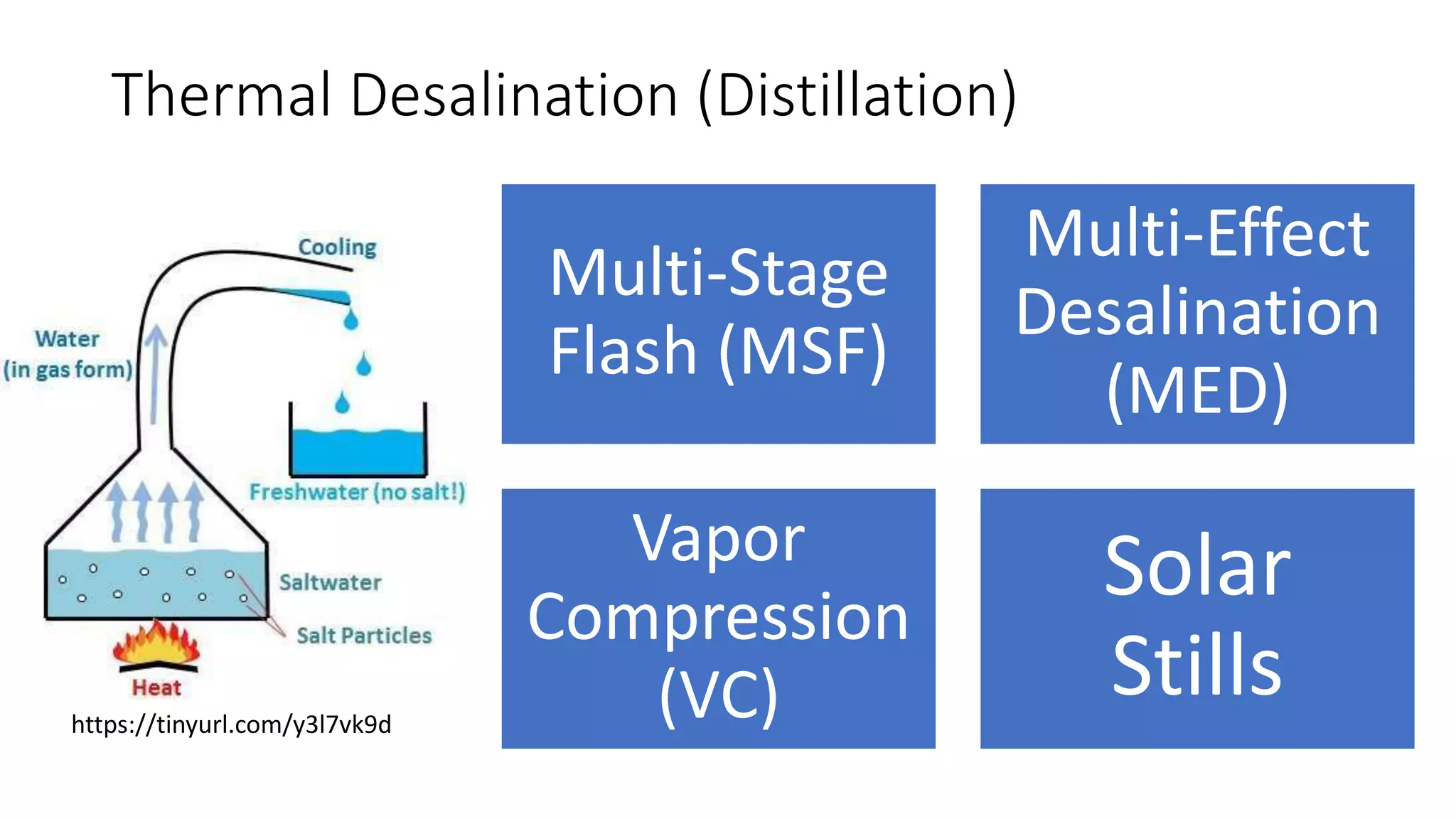

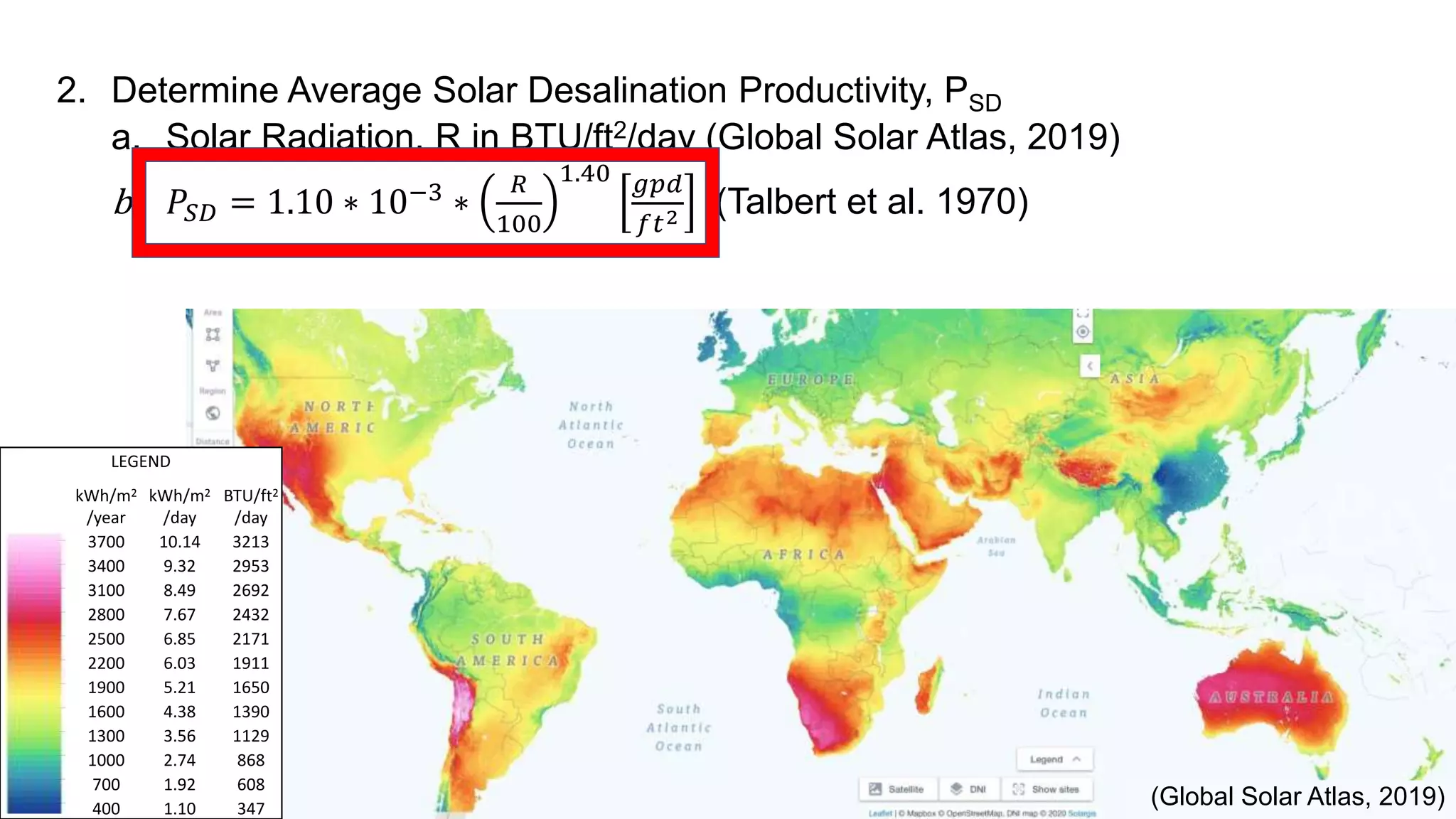

The document discusses appropriate desalination technologies for remote communities, highlighting the water crisis faced by 800 million people without potable water. It presents various desalination methods, including membrane and thermal processes, and explores the importance of sustainable development and local resources in designing effective systems. A case study on a water treatment system in Haiti emphasizes the need for community involvement and proper sizing of systems to meet local demands.

![(UN FAO, 2020)

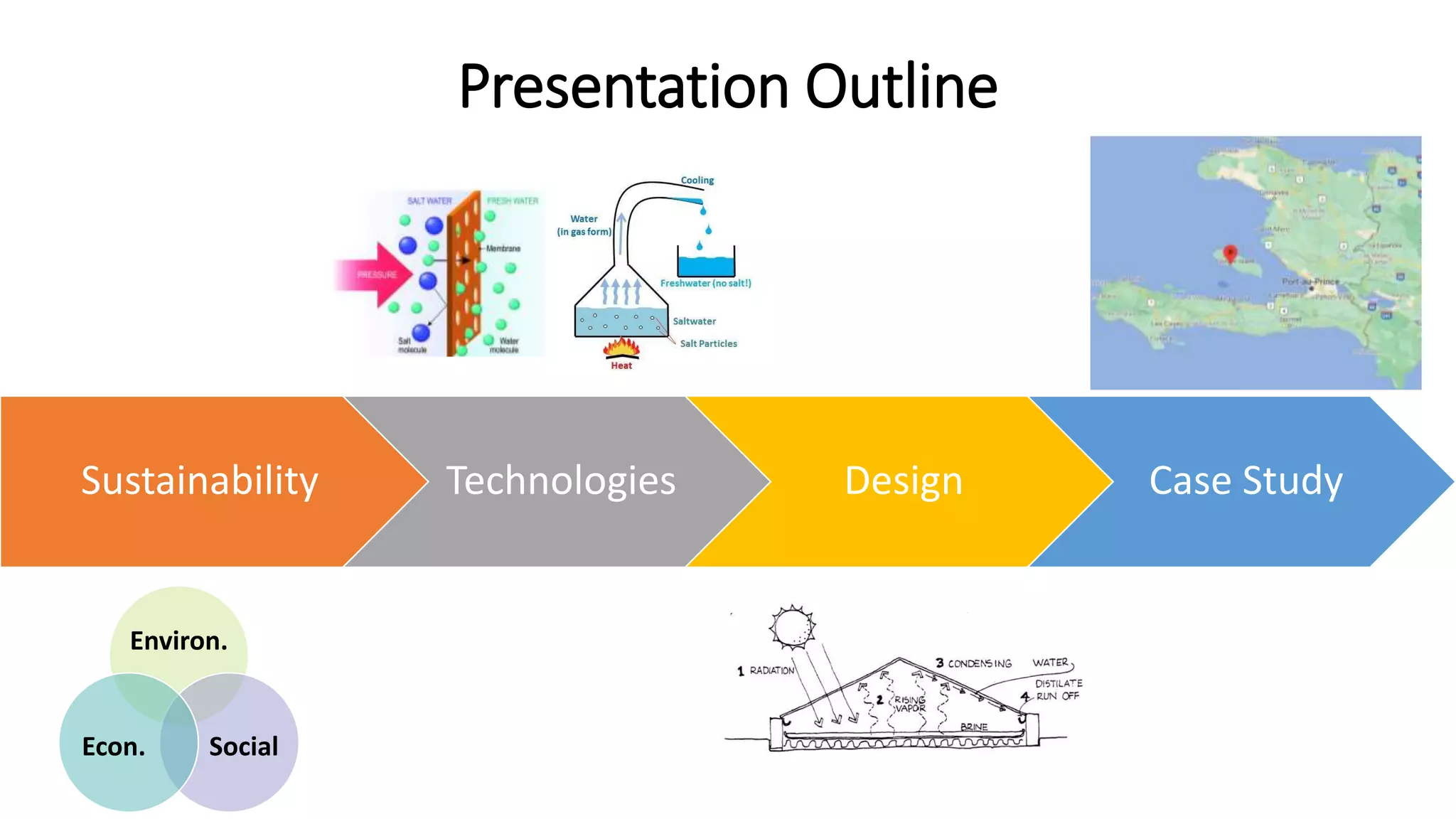

3. Rainwater Harvesting (RWH) Productivity, PRWH

• Find annual average rainfall, RW [feet/day] (UN FAO or regional data)

• 𝑉𝑅𝑊𝐻 = 0.8 ∗ 𝑅𝑊 ∗ 𝐴 [gpd] (USAID, 1982)

• 𝑃𝑅𝑊𝐻 =

𝑉 𝑅𝑊𝐻

𝐴

= 0.8 ∗ 𝑅𝑊

𝑔𝑝𝑑

𝑓𝑡2](https://image.slidesharecdn.com/msplanbtechnicalpresentation1-201207220413/75/Appropriate-Desalination-Technologies-for-Developing-Communities-17-2048.jpg)

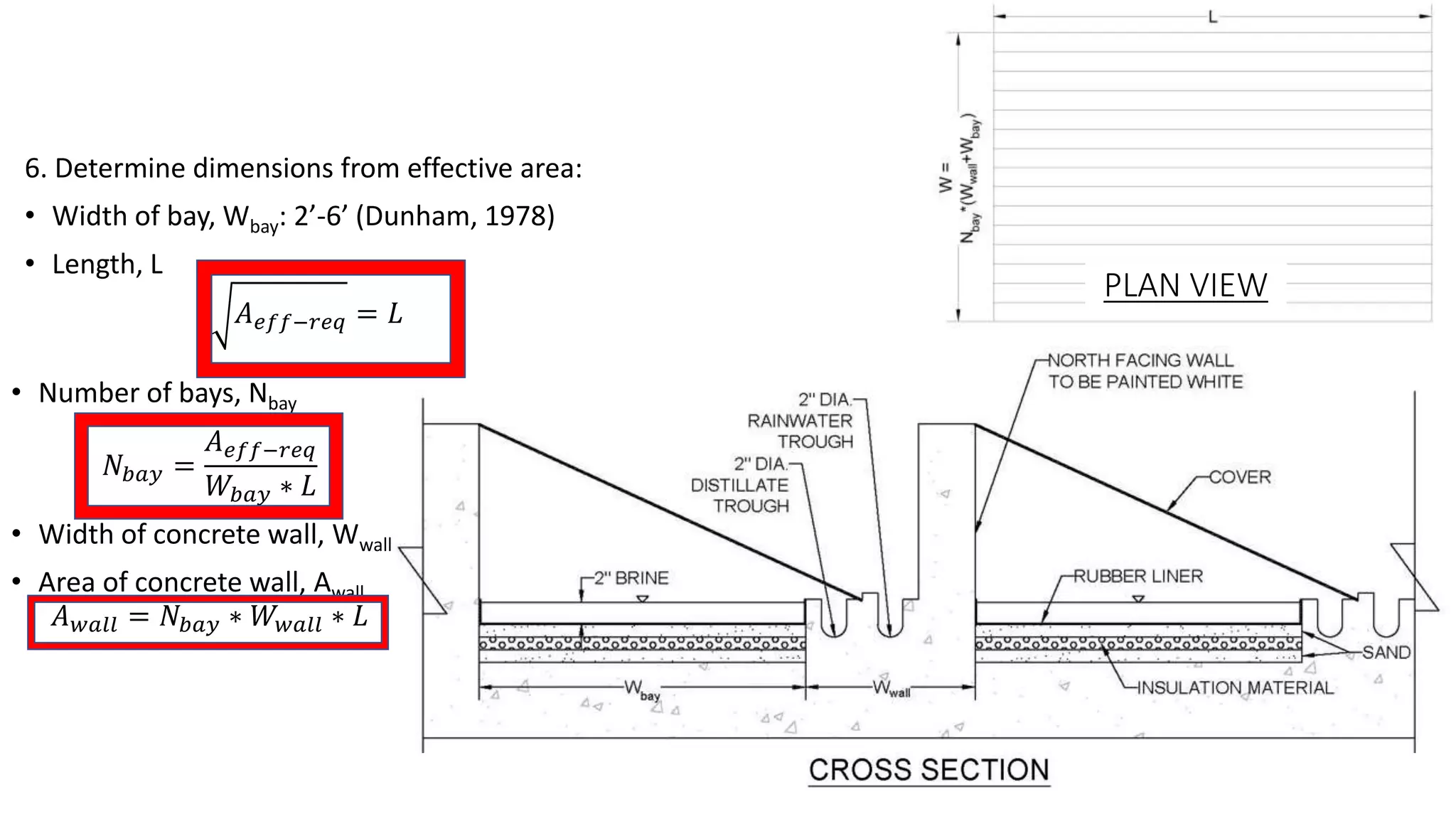

![4. Calculate Required Effective Area

𝐴 𝑒𝑓𝑓−𝑟𝑒𝑞 =

𝑄

𝑃 𝑆𝐷+𝑃 𝑅𝑊𝐻

[ft2]

5. Choose Geometry of Still:

(Dunham, 1978)](https://image.slidesharecdn.com/msplanbtechnicalpresentation1-201207220413/75/Appropriate-Desalination-Technologies-for-Developing-Communities-18-2048.jpg)