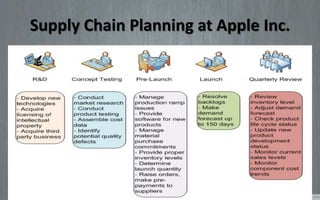

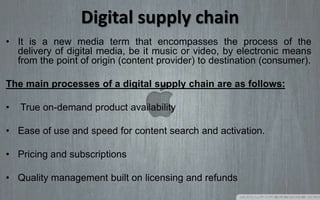

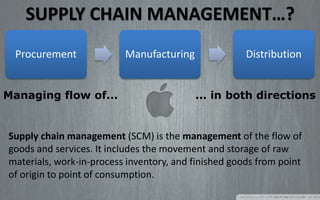

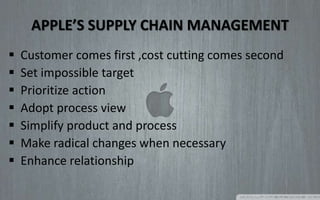

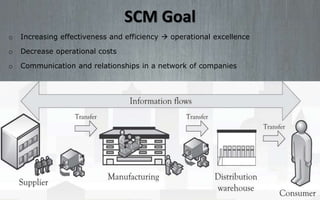

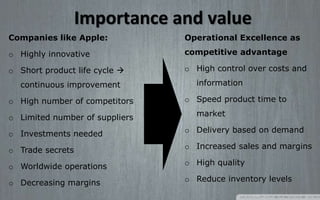

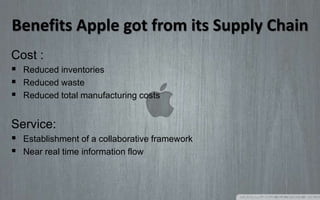

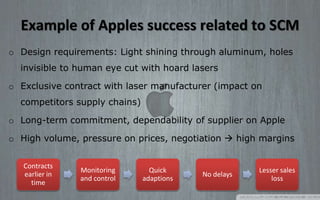

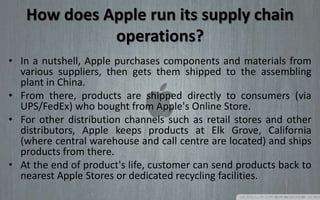

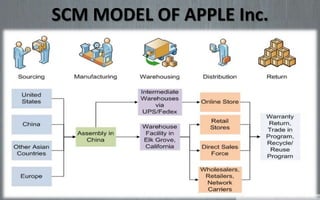

Apple is known for its innovative electronic devices and strong supply chain management. It was named the company with the best supply chain practices for the third year in a row. Apple manages both digital and physical supply chains efficiently at low cost by setting impossible targets, prioritizing action, simplifying processes, and enhancing supplier relationships. This operational excellence gives Apple a competitive advantage through high control over costs, speed to market, demand-based delivery, and high quality.