Australian Pipeline Valve (APV) complies with API-6A technical specifications for oil and gas valves. The document provides an overview of API-6A standards including:

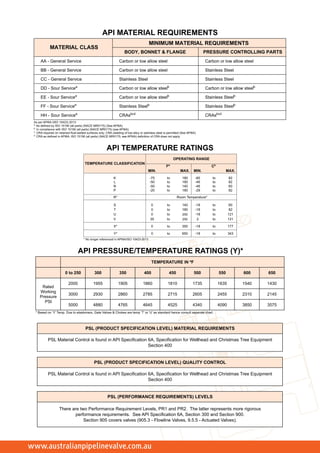

a) Pressure and temperature ratings for APV valves from 2000psi to 15,000psi and ratings L to Y.

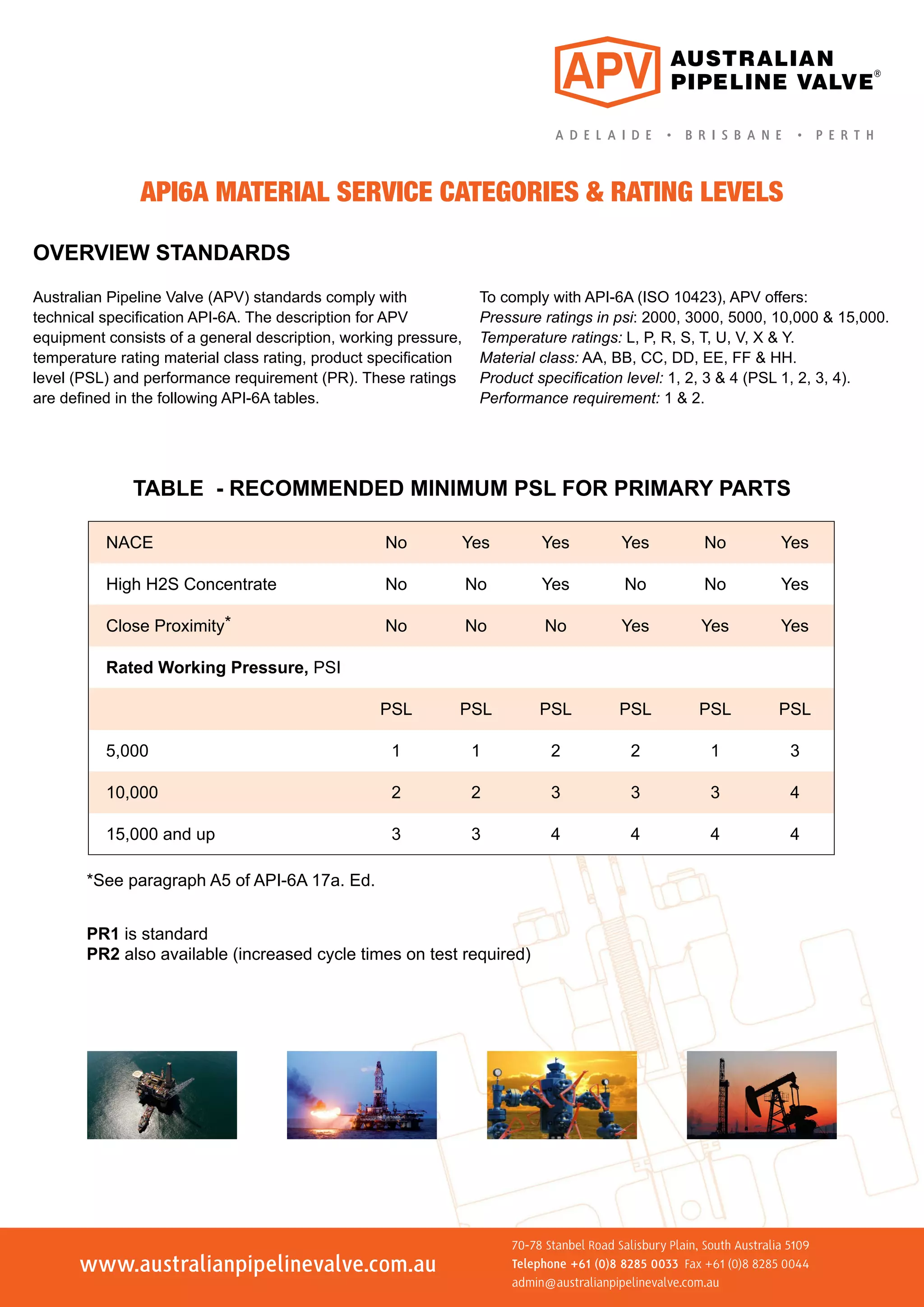

b) Material classes from AA to HH and Product Specification Levels 1 to 4.

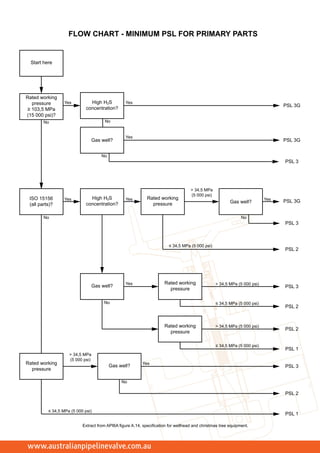

c) Charts showing minimum PSL requirements based on factors like pressure, H2S exposure.

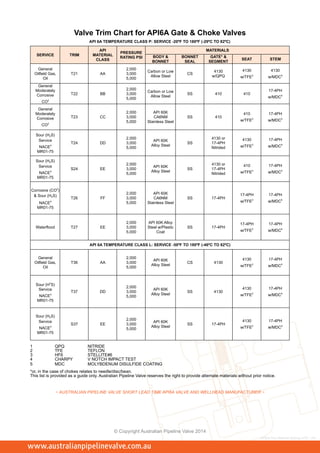

d) Descriptions of trim types for applications like sour gas, water, and temperature ranges.