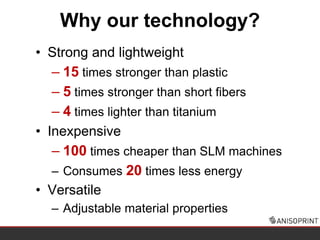

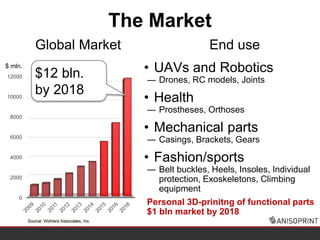

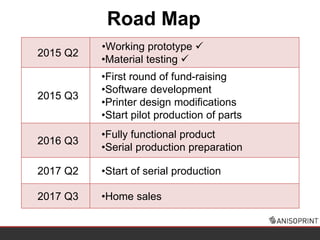

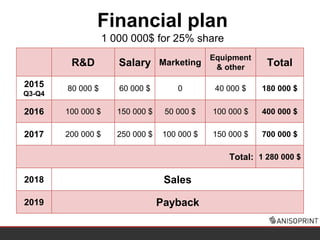

Anisoprint Composer is introducing a revolutionary new 3D printer that is able to introduce continuous carbon fiber into plastics, making the printed materials over a dozen times stronger yet lighter and more affordable than other 3D printing technologies. Their 3D printer technology produces parts that are 15 times stronger than plastic, 5 times stronger than short fiber composites, and 4 times lighter than titanium, at a fraction of the cost of other high-end 3D printers. The company is seeking $1 million in funding to continue R&D, launch a working prototype, and prepare for serial production and sales.