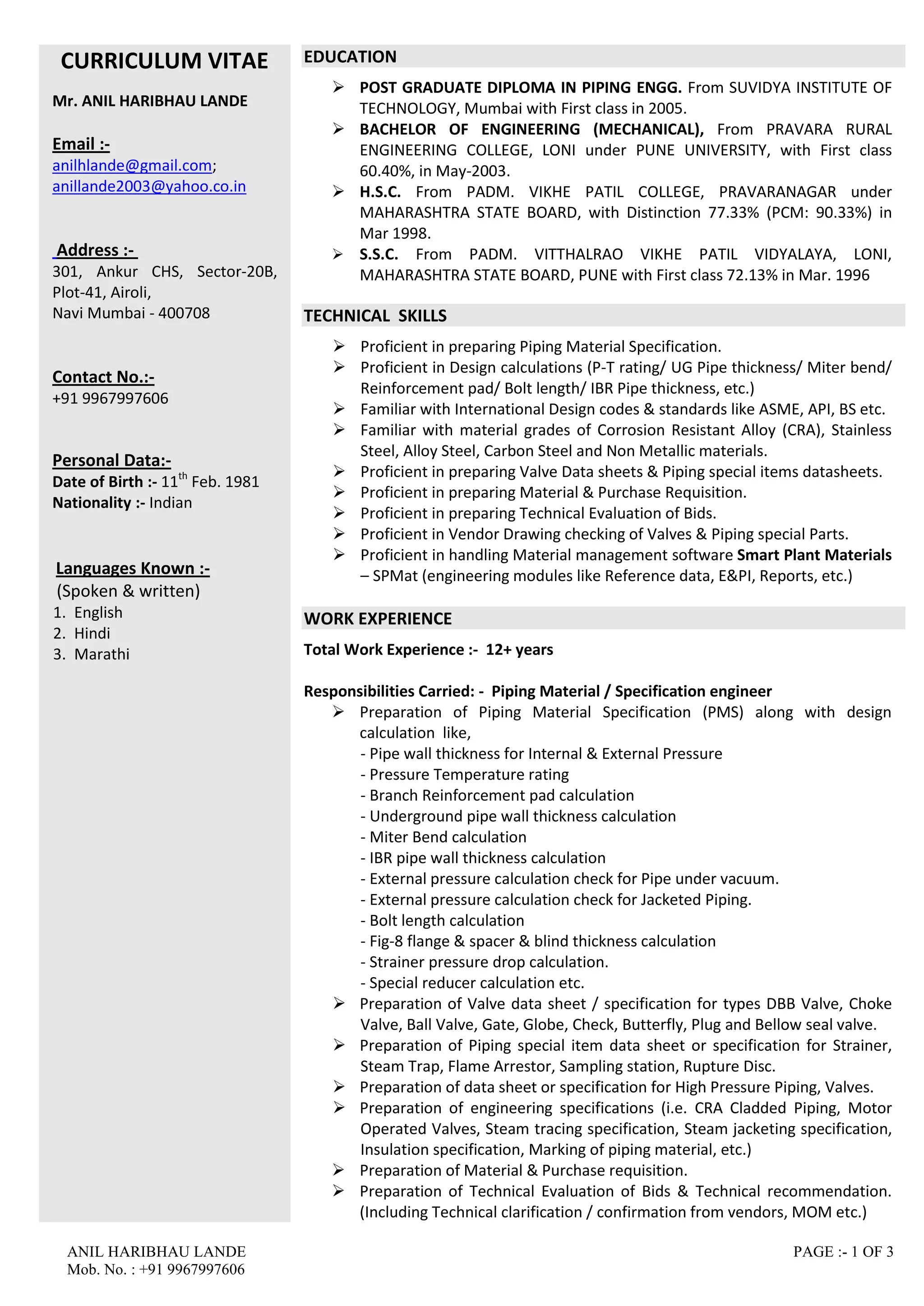

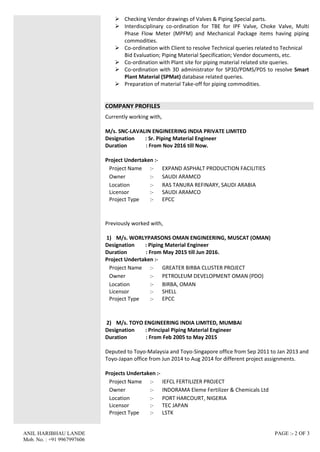

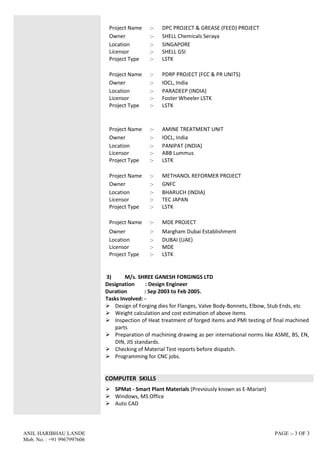

This document is a 3-page curriculum vitae for Anil Haribhau Lande. It includes personal details like his date of birth and contact information. It outlines his educational qualifications including a post-graduate diploma in piping engineering and a bachelor's degree in mechanical engineering. It also lists his technical skills and over 12 years of work experience in roles like piping material engineer. It provides details of current and previous employers and projects he has worked on.