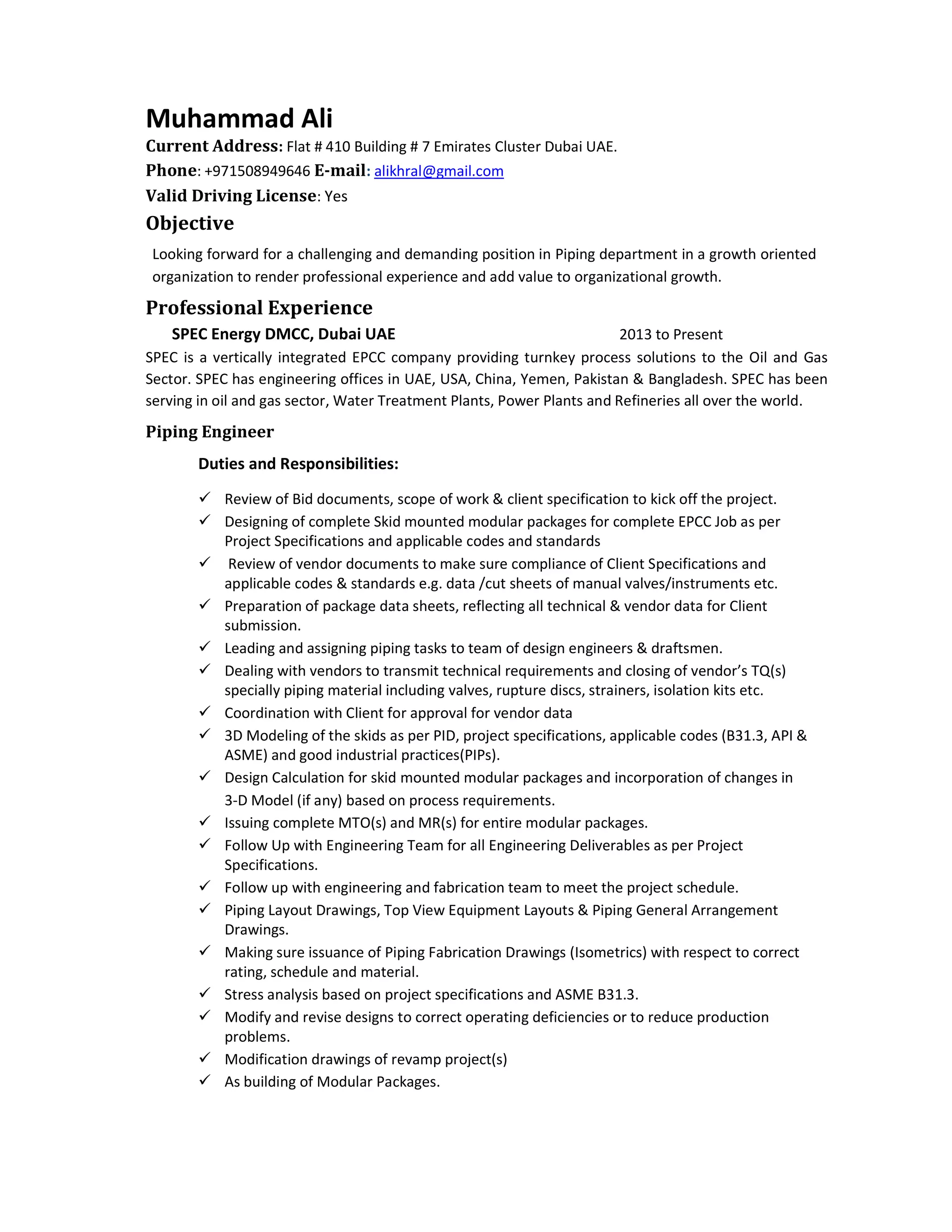

Muhammad Ali is a piping engineer currently working for SPEC Energy DMCC in Dubai. He has over 5 years of experience in designing and engineering piping systems for oil and gas projects. Some of his major projects include the Gambat South Gas Processing Facility in Pakistan and the Crude Oil Processing Facility for Hunt Oil's Ain Sifni project in Iraq. He holds a BSc in Mechanical Engineering and is proficient in various piping design software such as AutoCAD Plant 3D, Cadworx, and CAESAR II.