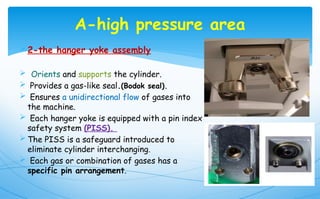

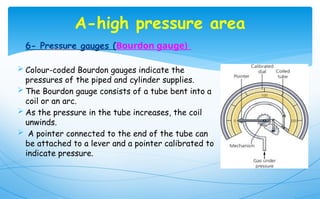

The document provides a detailed overview of the anesthesia machine, focusing specifically on its pneumatic component and its safety features developed over nearly 100 years. It covers the structure of the high, intermediate, and low-pressure areas, including components such as pressure regulators, flow meters, and vaporizers, while emphasizing the critical importance of proper machine checks and training to prevent mishaps. The document also highlights international and national safety standards applicable to anesthesia machines, which aim to enhance patient safety during anesthesia delivery.