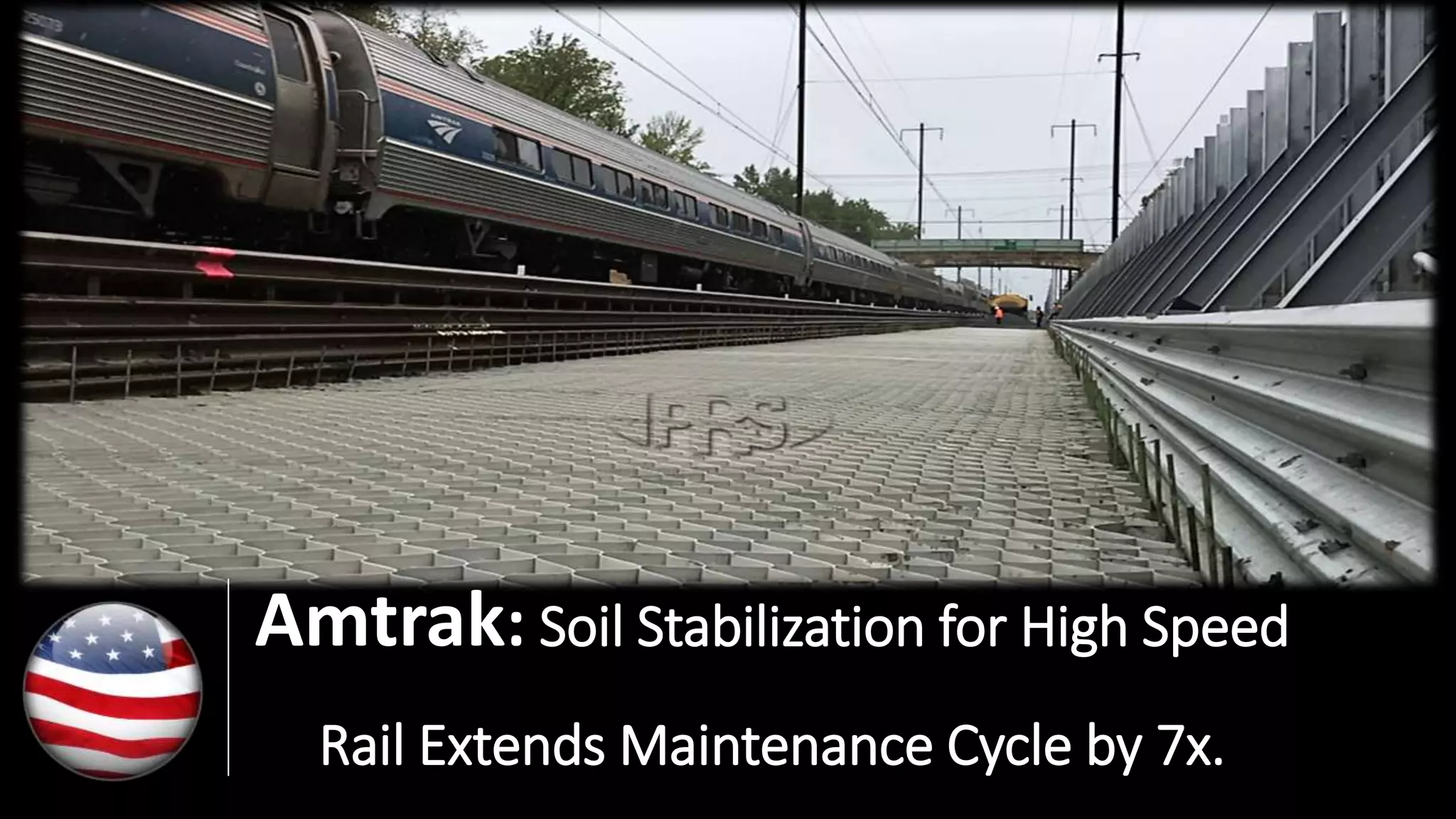

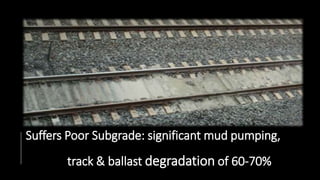

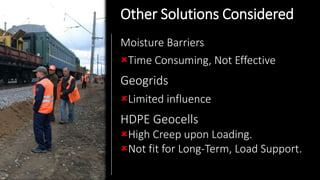

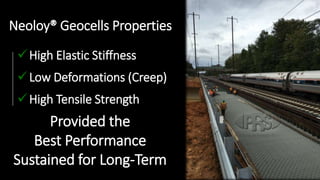

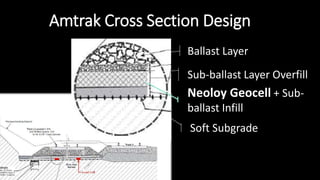

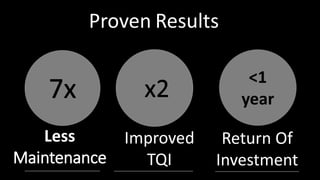

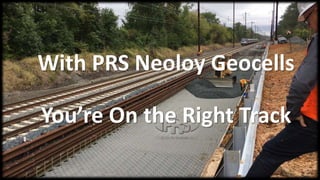

Amtrak has implemented PRS Neoloy® geocells for soil stabilization on its high-speed rail corridor between Washington DC and Boston, which suffers from poor subgrade causing significant degradation. The geocells offer high elastic stiffness, low deformations, and high tensile strength, resulting in immediate installation benefits and long-term performance without the need for subgrade replacement. The solution has extended the maintenance cycle by seven times, leading to less maintenance and a quick return on investment.