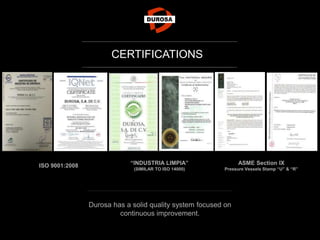

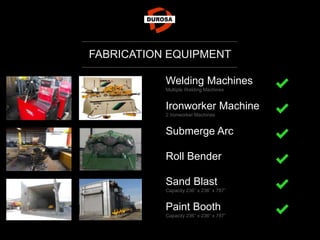

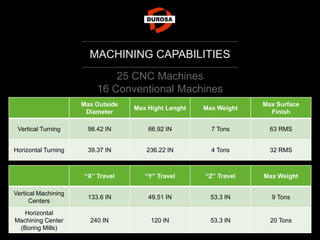

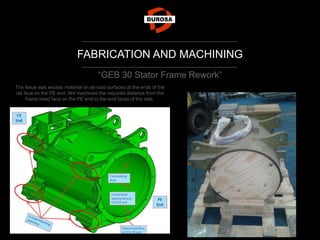

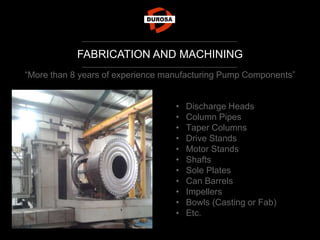

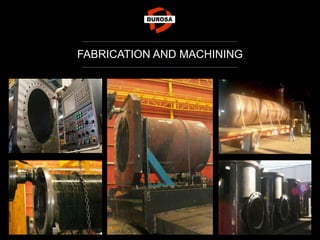

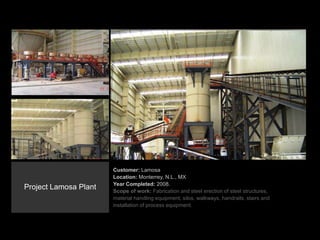

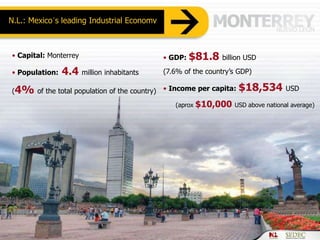

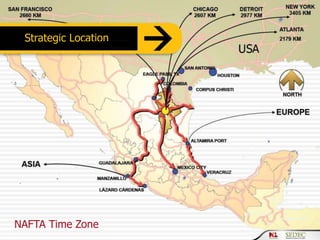

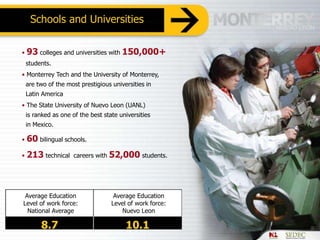

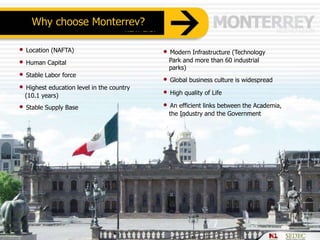

Durosa is a regional leader in fabrication and precision machining located in northeast Mexico. It has over 200,000 square feet of facilities and equipment for projects of any size. Founded in 1982, Durosa has expanded its capabilities and certifications while maintaining constant growth. It prides itself on quality, efficiency, and being a reliable supplier with world-class standards. Durosa has experience manufacturing components for various industries such as oil and gas, steel, and power generation. Its location provides competitive advantages such as access to a skilled labor force and proximity to the US market.