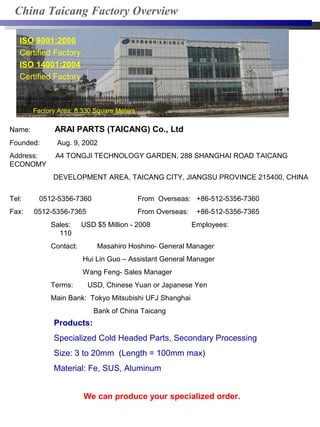

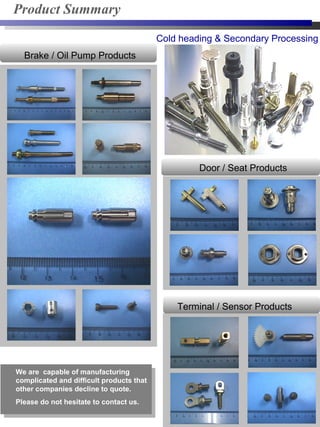

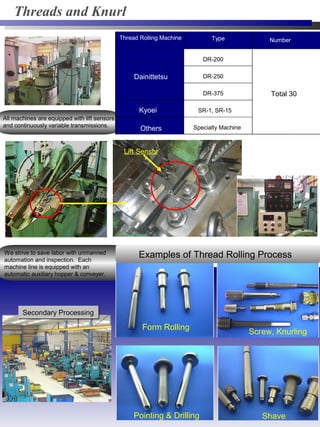

Arai Parts Co., Ltd. is a Japanese company founded in 1972 that manufactures specialized cold headed parts and assembly parts through cold heading and secondary processing. The company has 83 employees in Japan and 110 employees in its China factory. It produces parts for the automotive and electronics industries and has certified quality and environmental management systems.