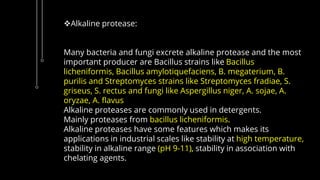

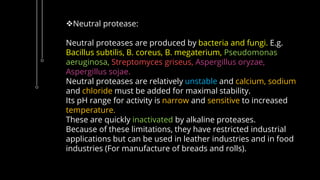

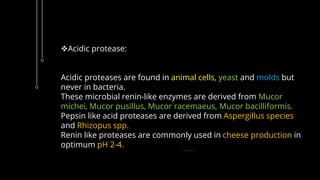

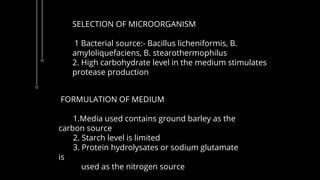

1. Protease enzymes are produced industrially using bacteria and fungi. Bacillus licheniformis is commonly used to produce alkaline proteases for detergents.

2. Proteases have various industrial applications including in detergents, food processing, leather tanning, and medical treatments. They are the most important industrial enzyme worldwide.

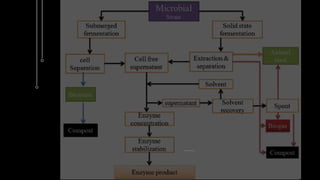

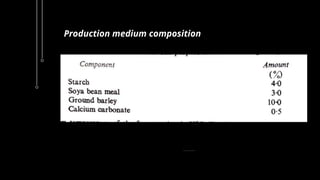

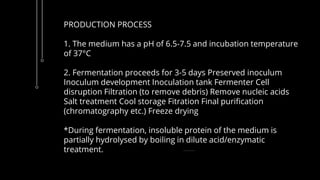

3. Protease production involves selecting a microbial strain, optimizing growth media, fermentation using the selected strain, and downstream recovery and purification of the enzymes. Various process parameters like pH, temperature and nutrient levels are controlled during fermentation and recovery.