This document summarizes a project to develop a new technology for processing sewage sludge into phosphate fertilizers. The technology would provide an alternative raw material source and solve issues with current fertilizer production methods. Key points include:

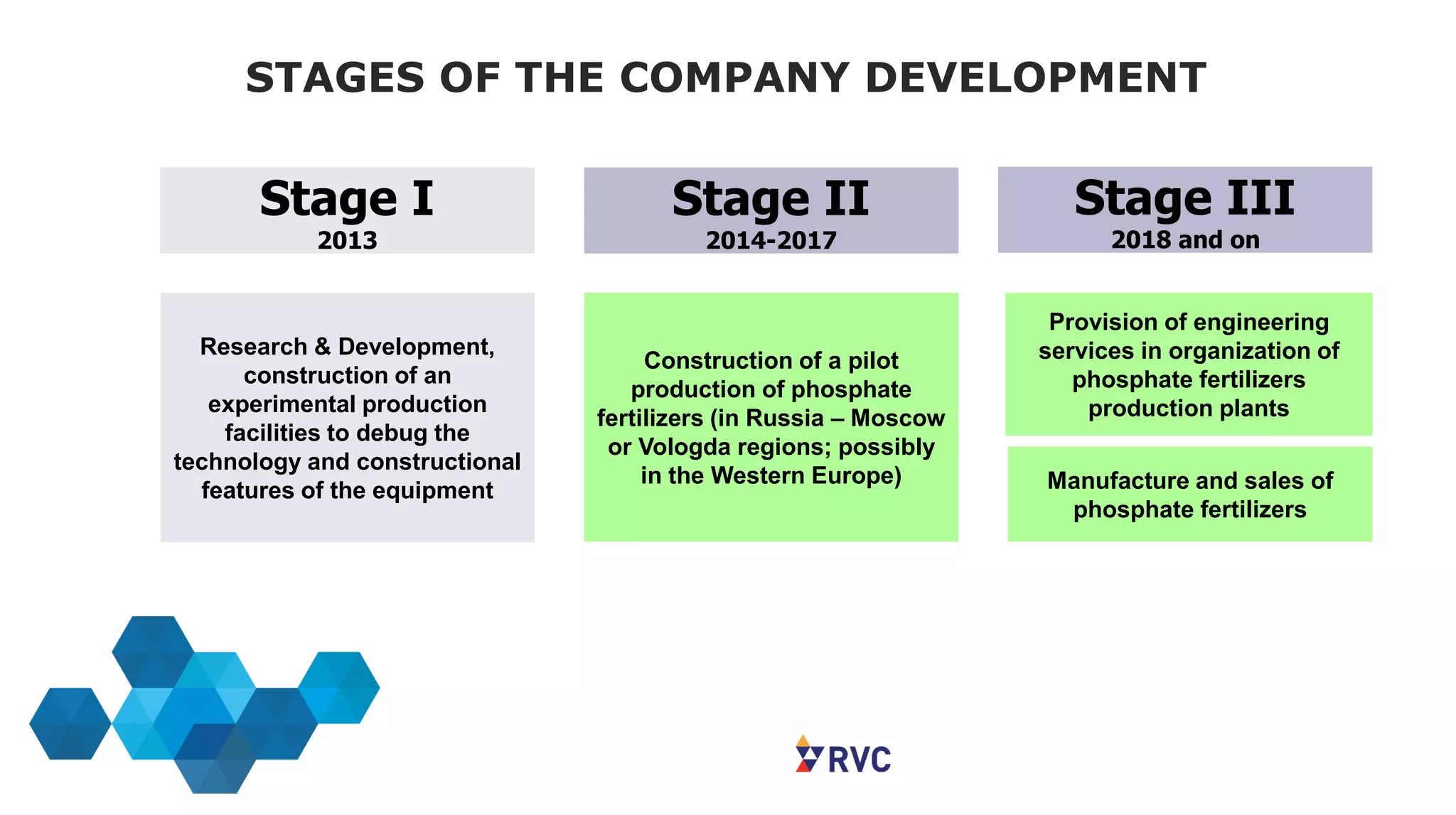

- The project involves R&D of a new processing technology, construction of a pilot plant, attracting investment for commercial production.

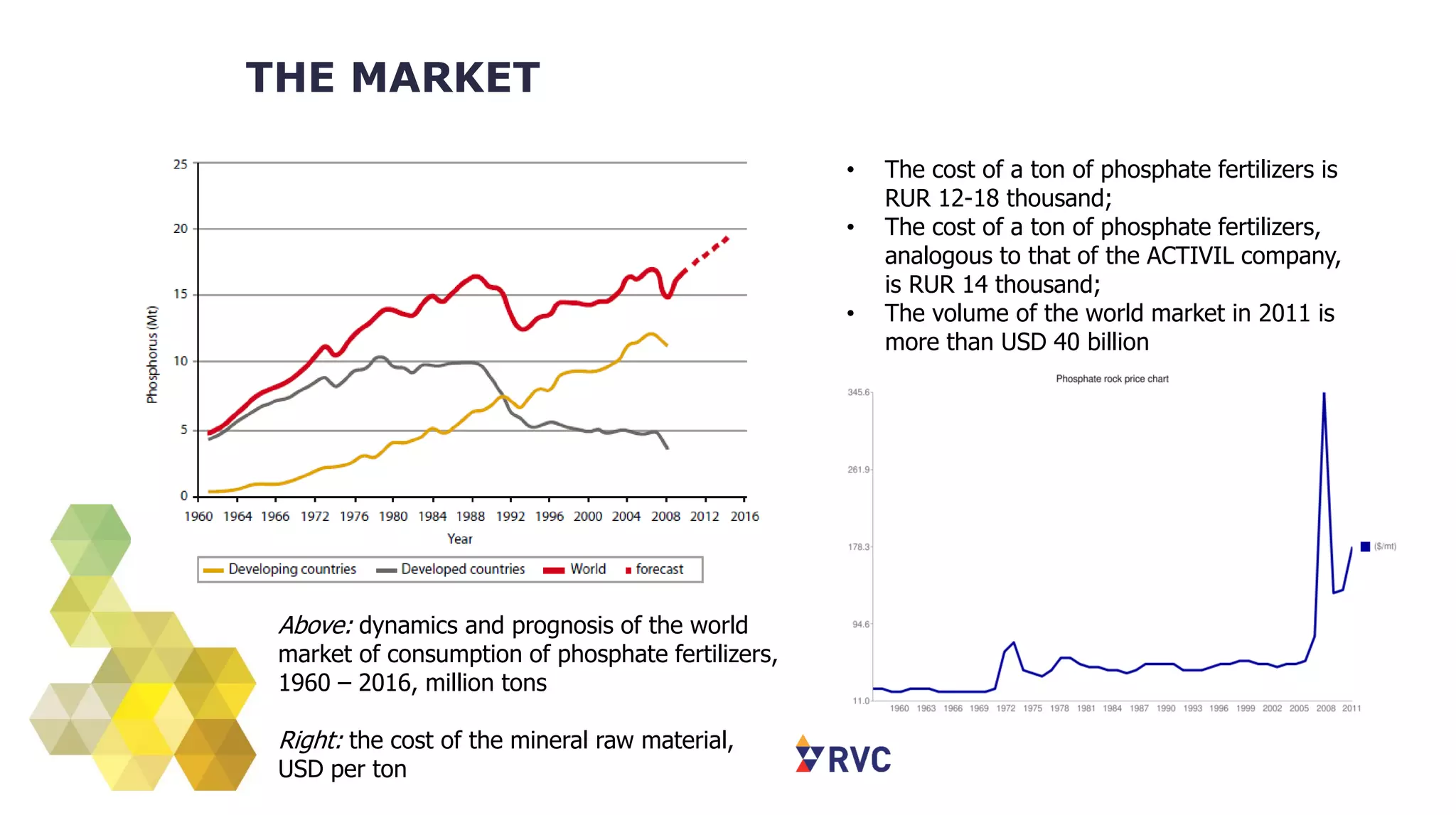

- The global phosphate fertilizer market was over $40 billion in 2011 and is projected to grow 5% annually, creating market potential.

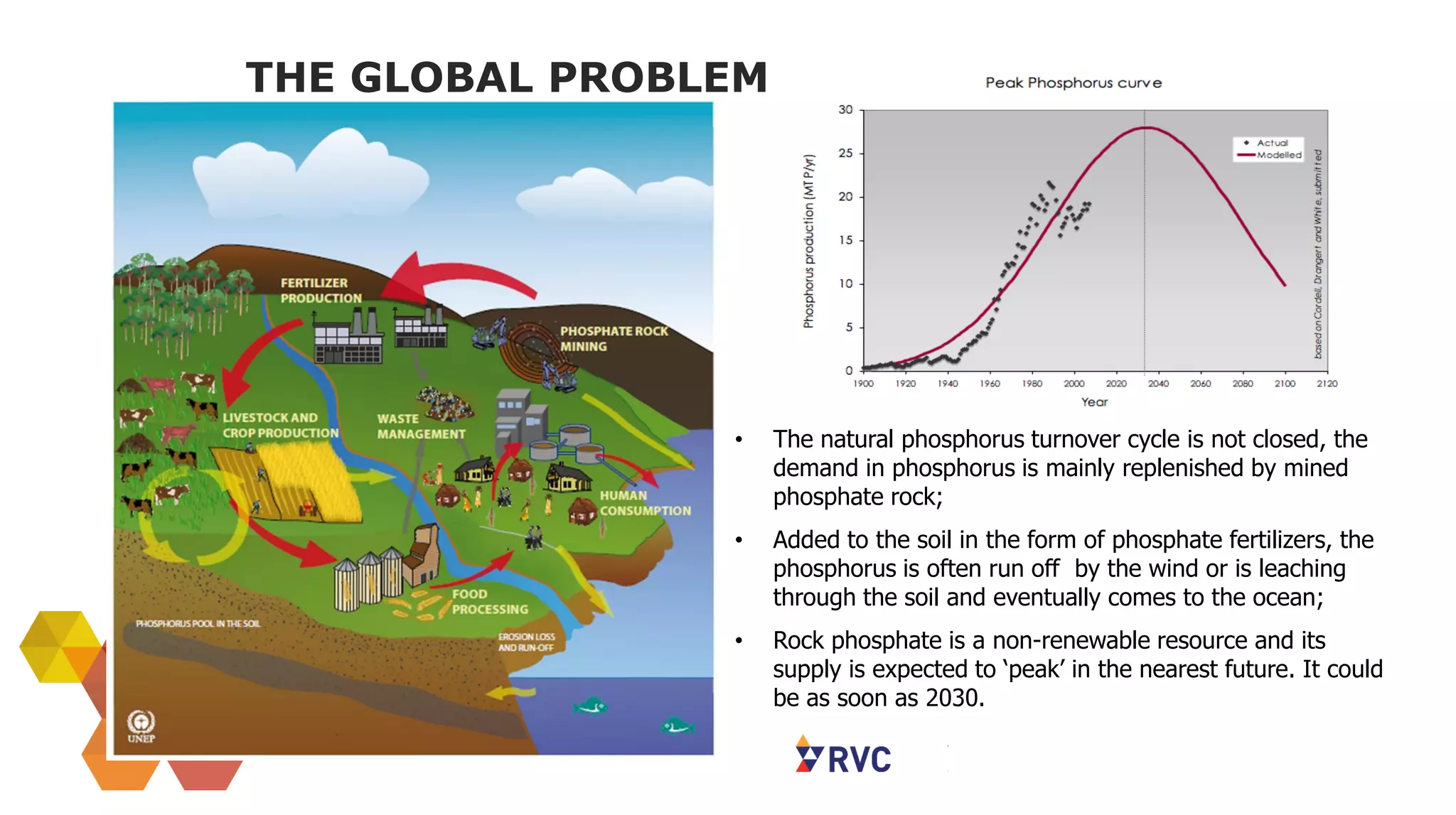

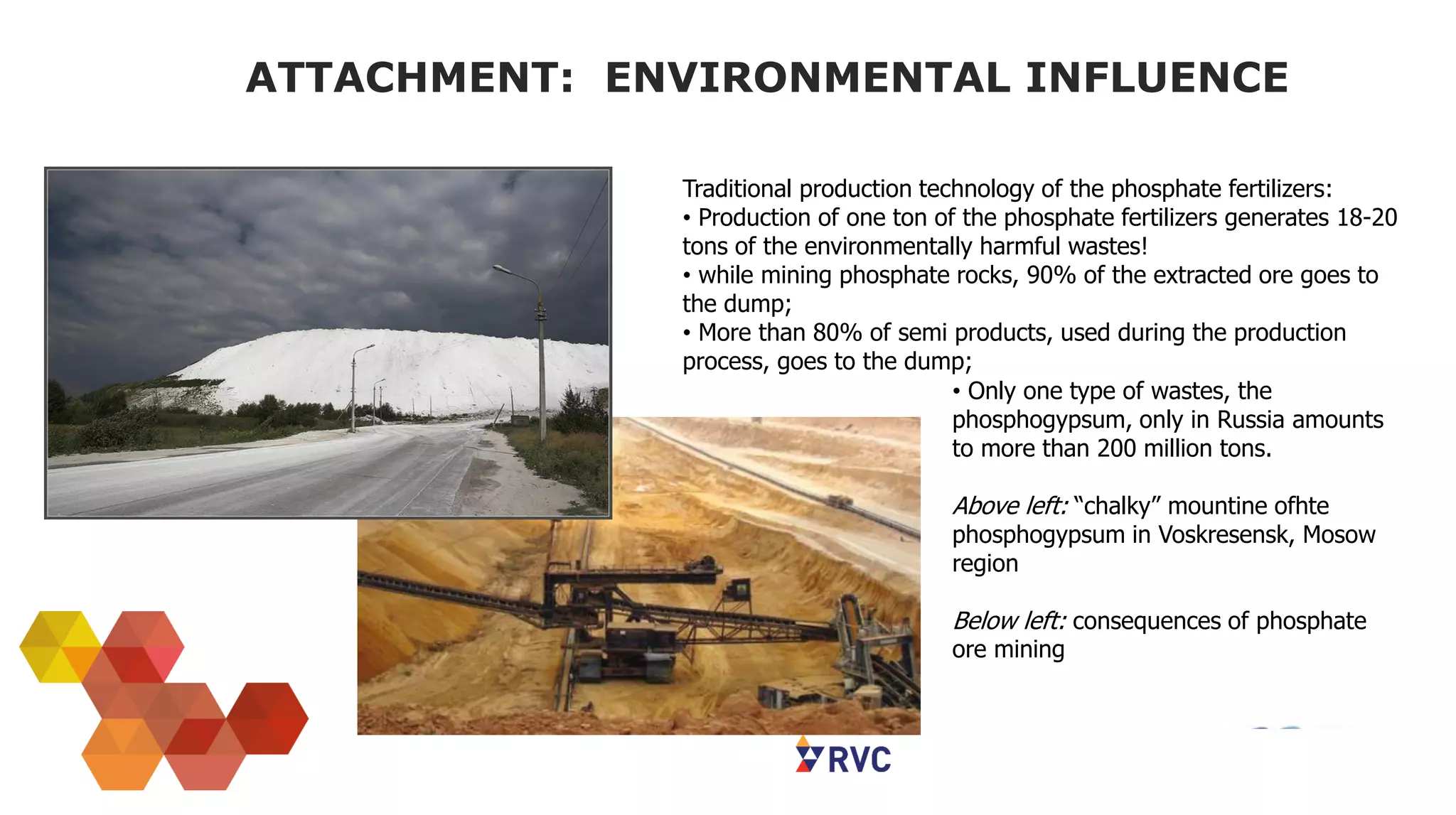

- Current fertilizer production relies on non-renewable phosphate rock and causes environmental damage, while sewage sludge disposal is an ongoing problem. The new technology aims to close the phosphorus cycle in a more