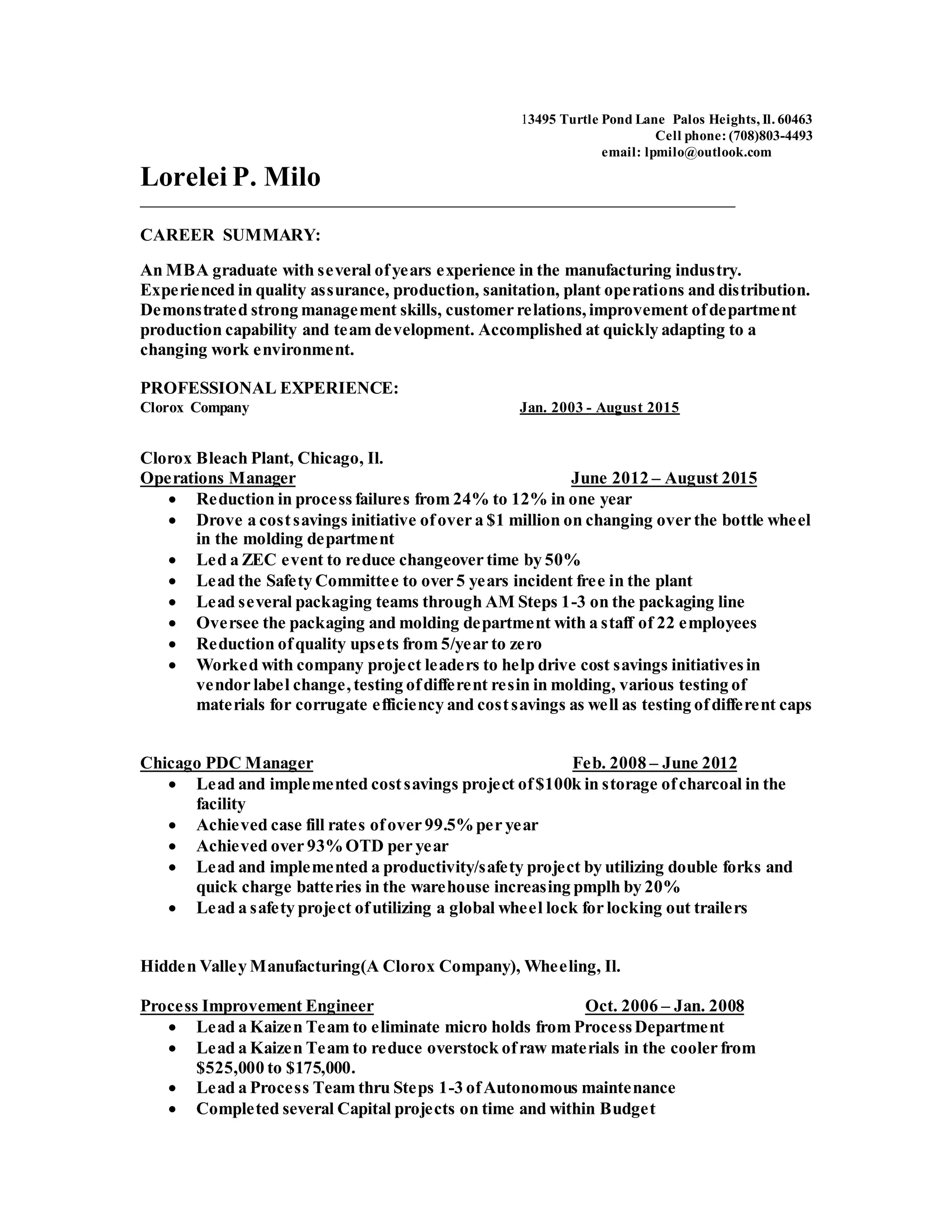

Lorelei P. Milo has over 15 years of experience in manufacturing operations and quality assurance roles. She has a proven track record of driving cost savings, improving production processes, and ensuring quality standards. Her experience spans multiple industries and includes roles as an operations manager, process engineer, quality assurance manager, and production supervisor. She holds an MBA in Operations and a B.S. in Biology.