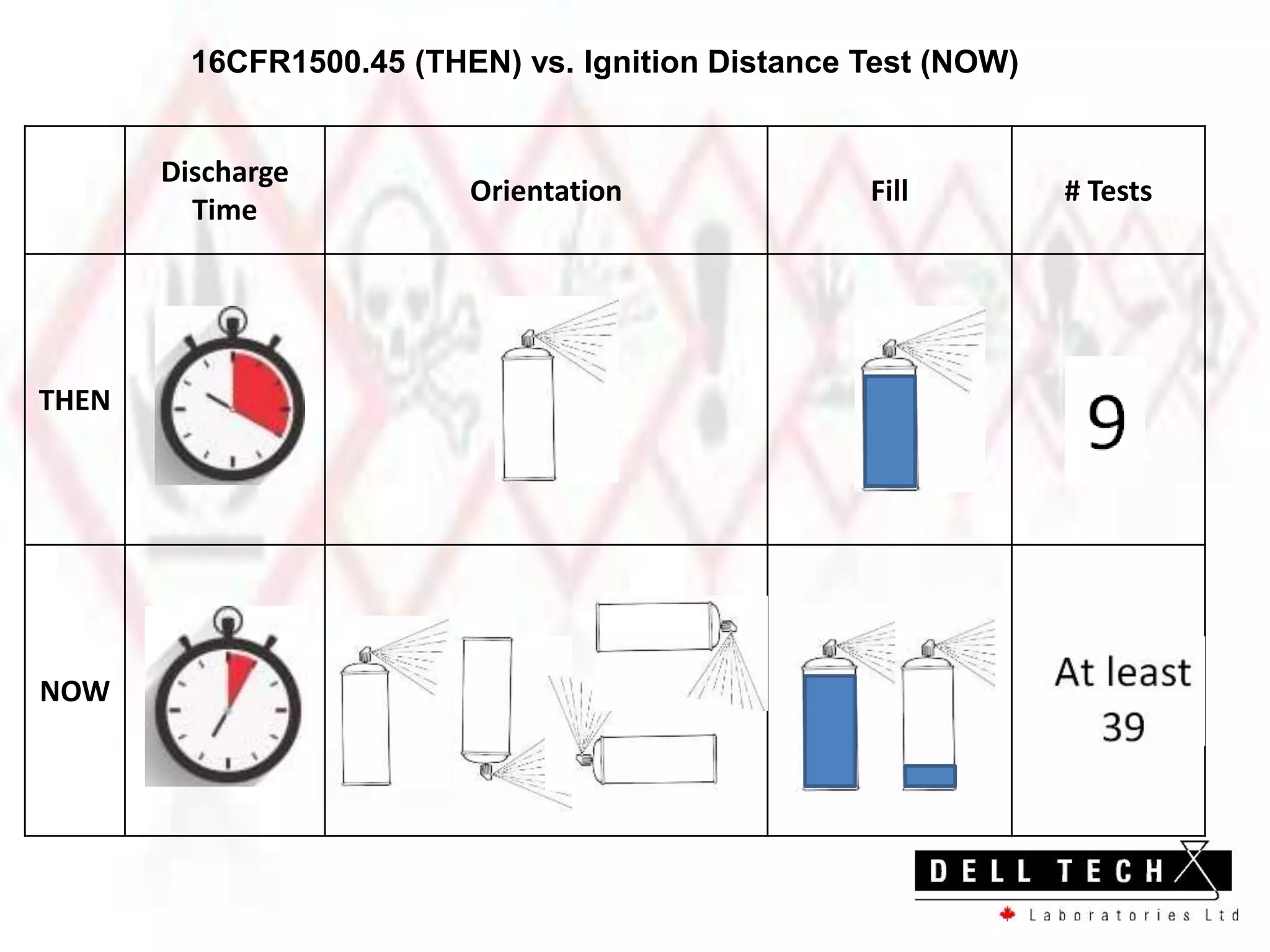

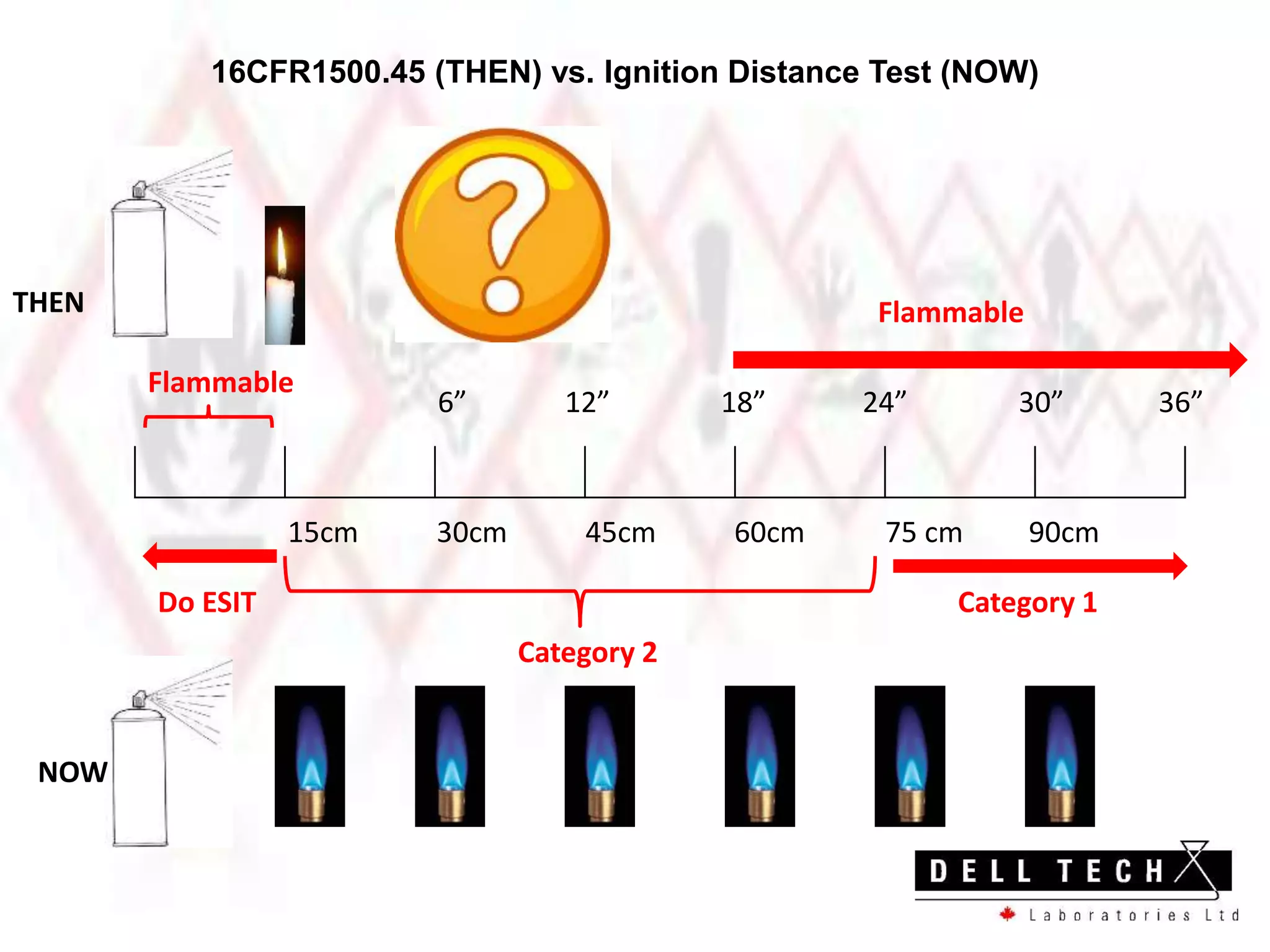

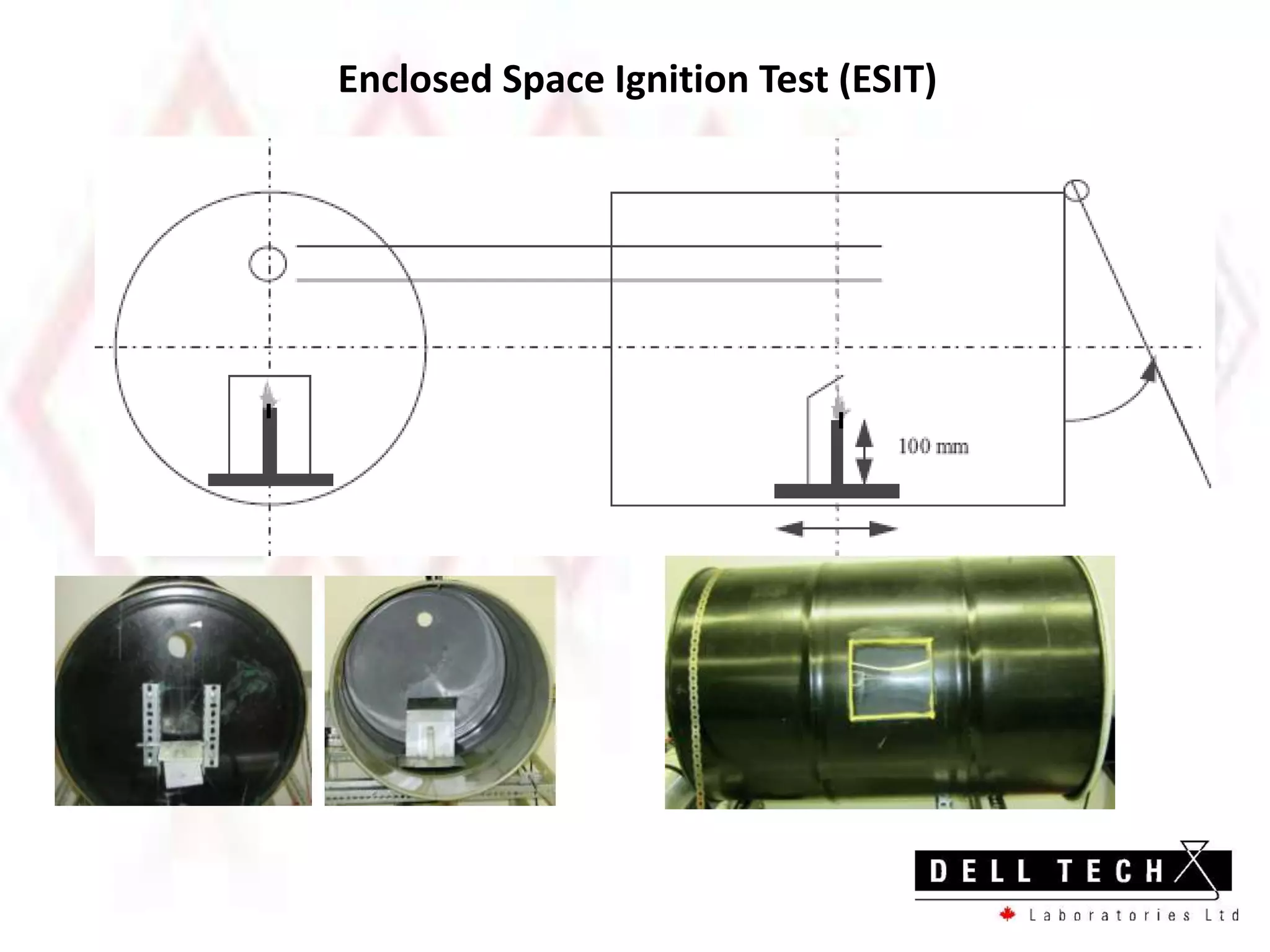

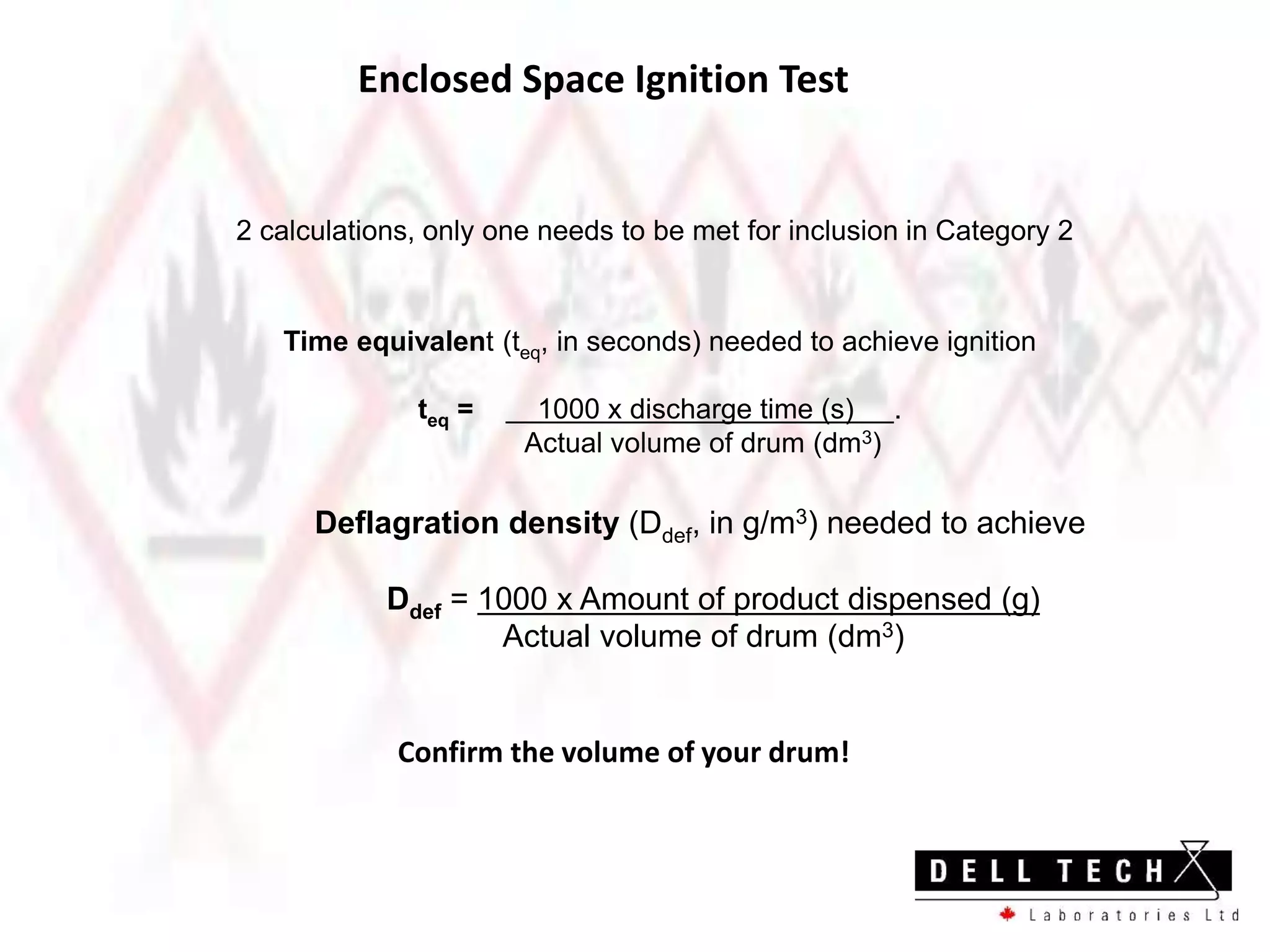

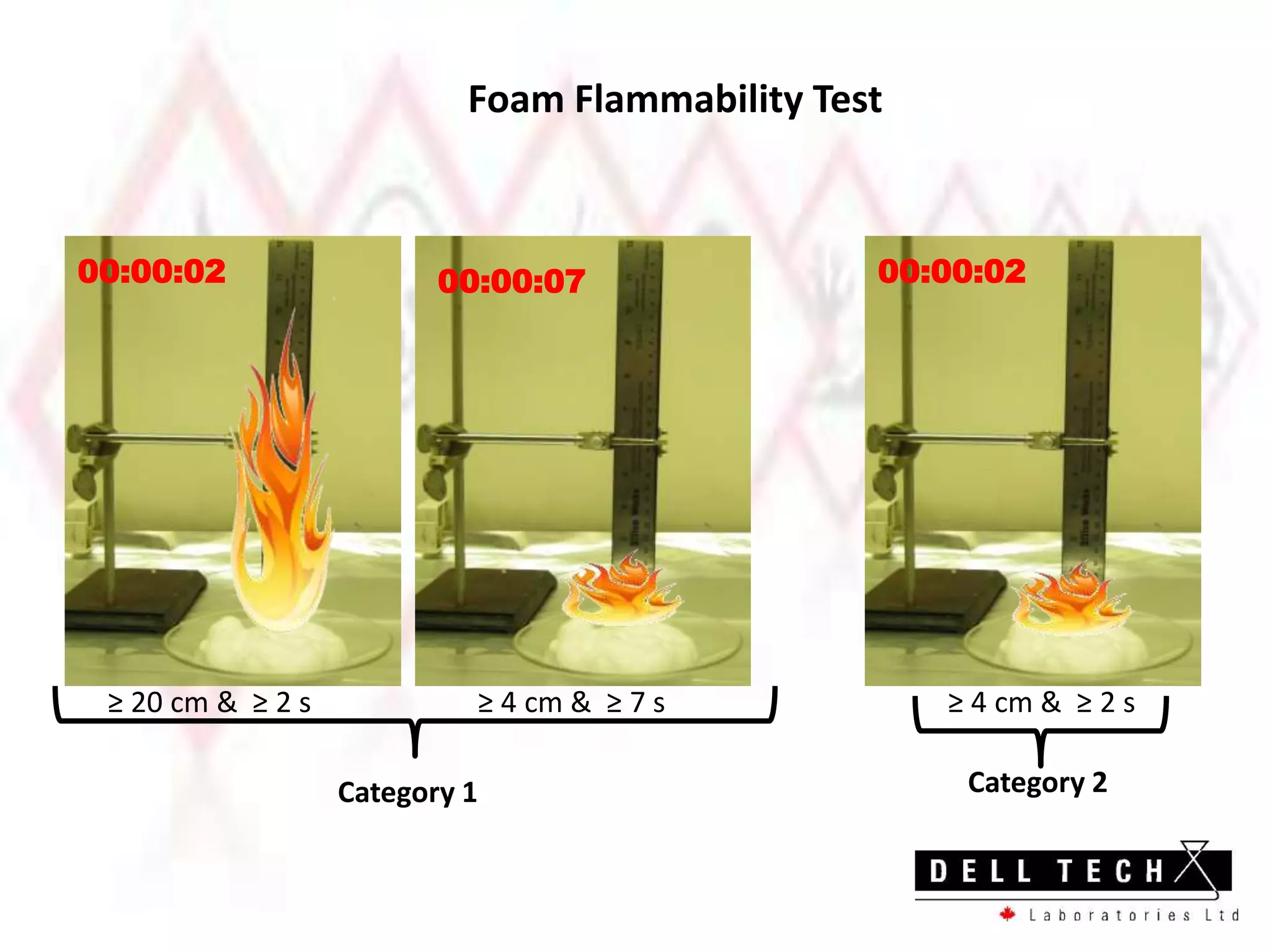

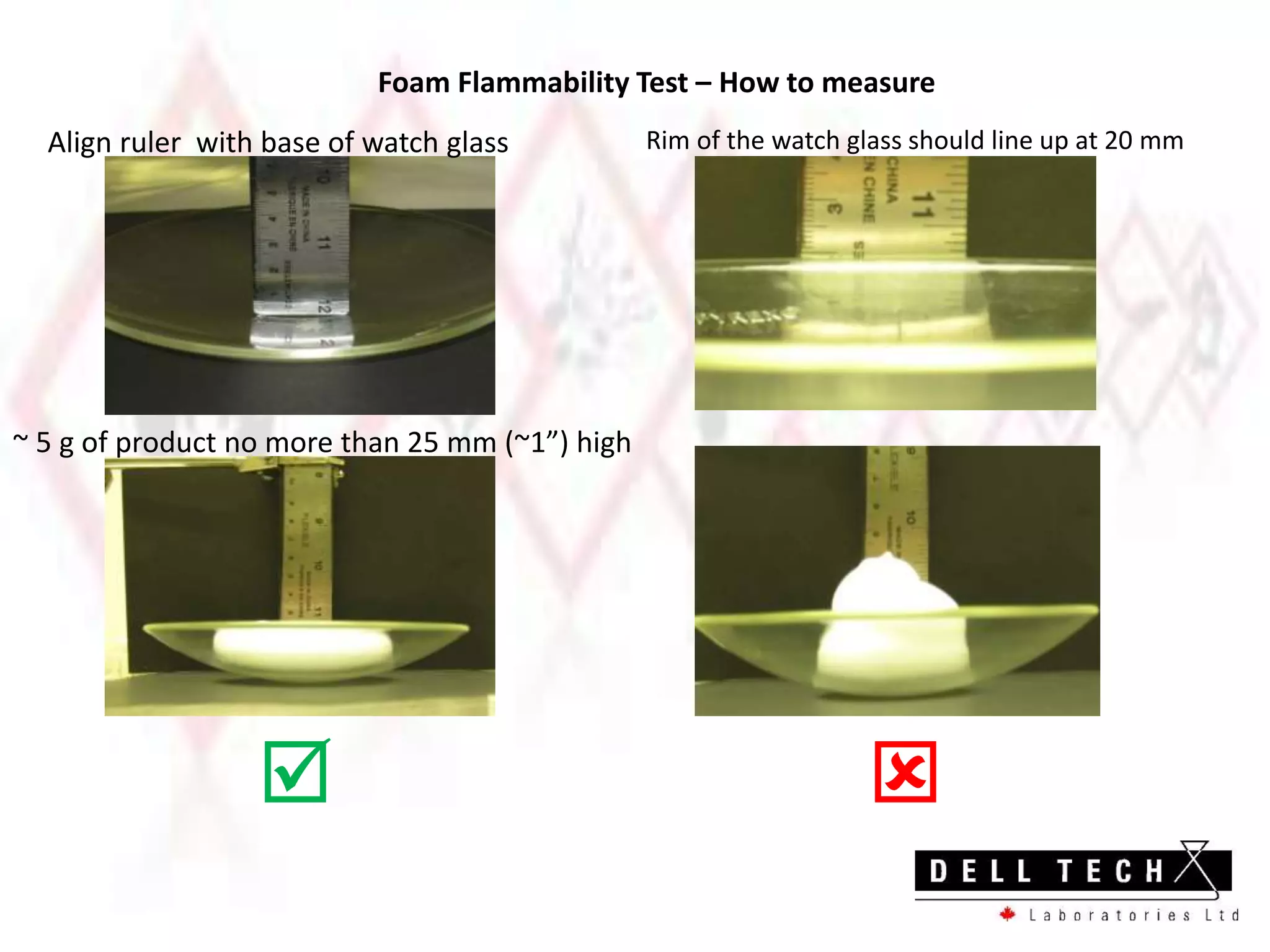

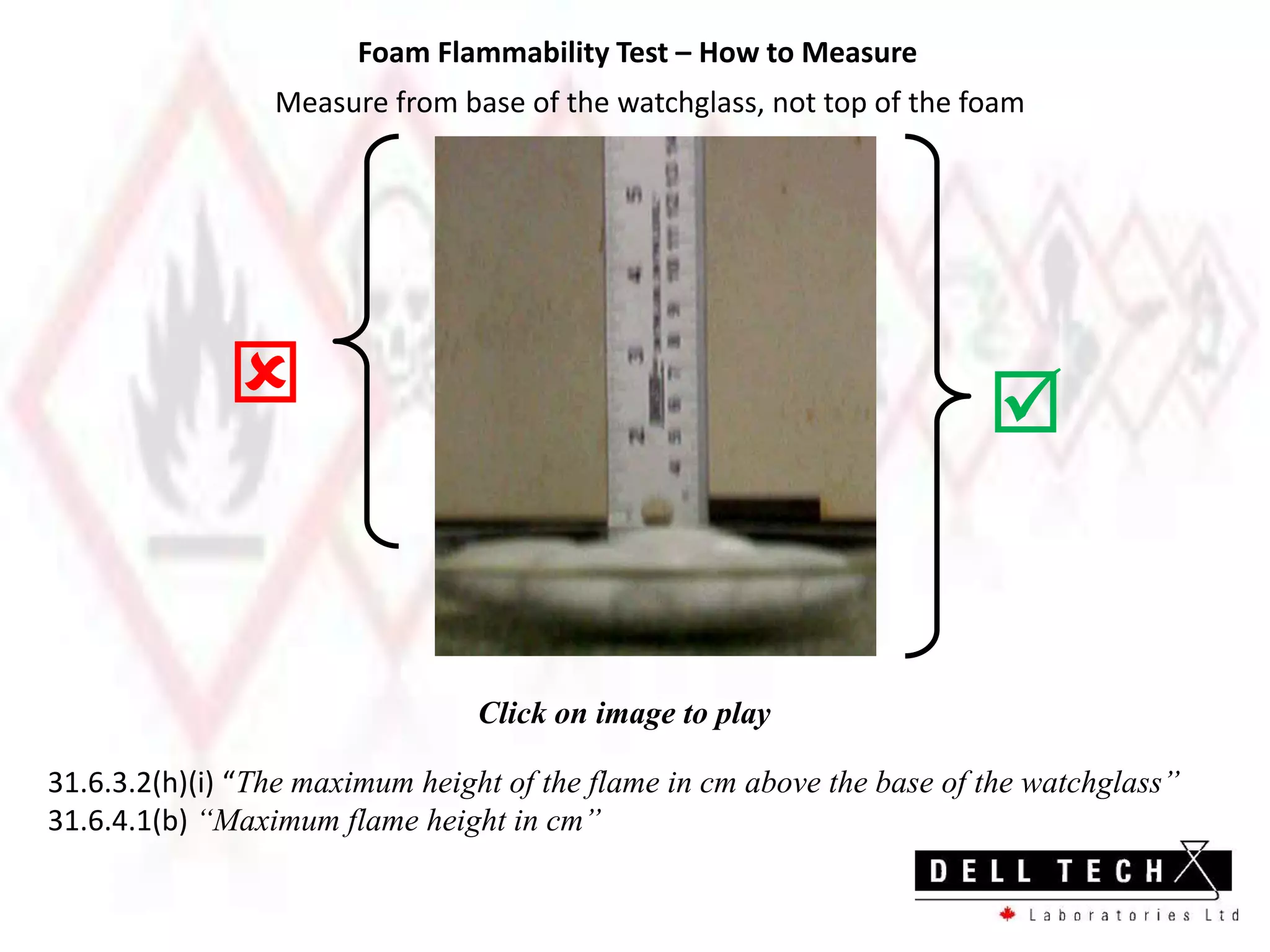

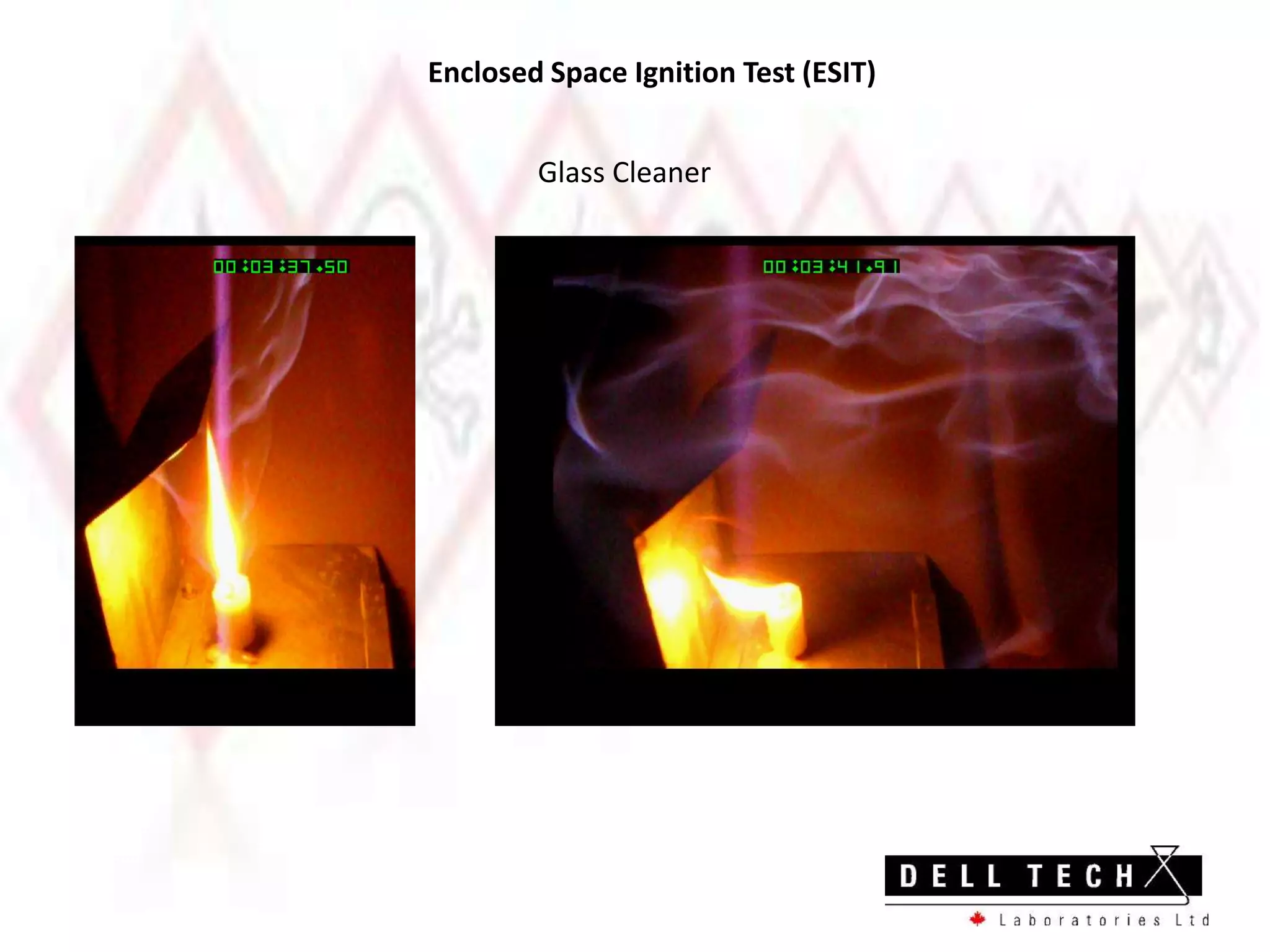

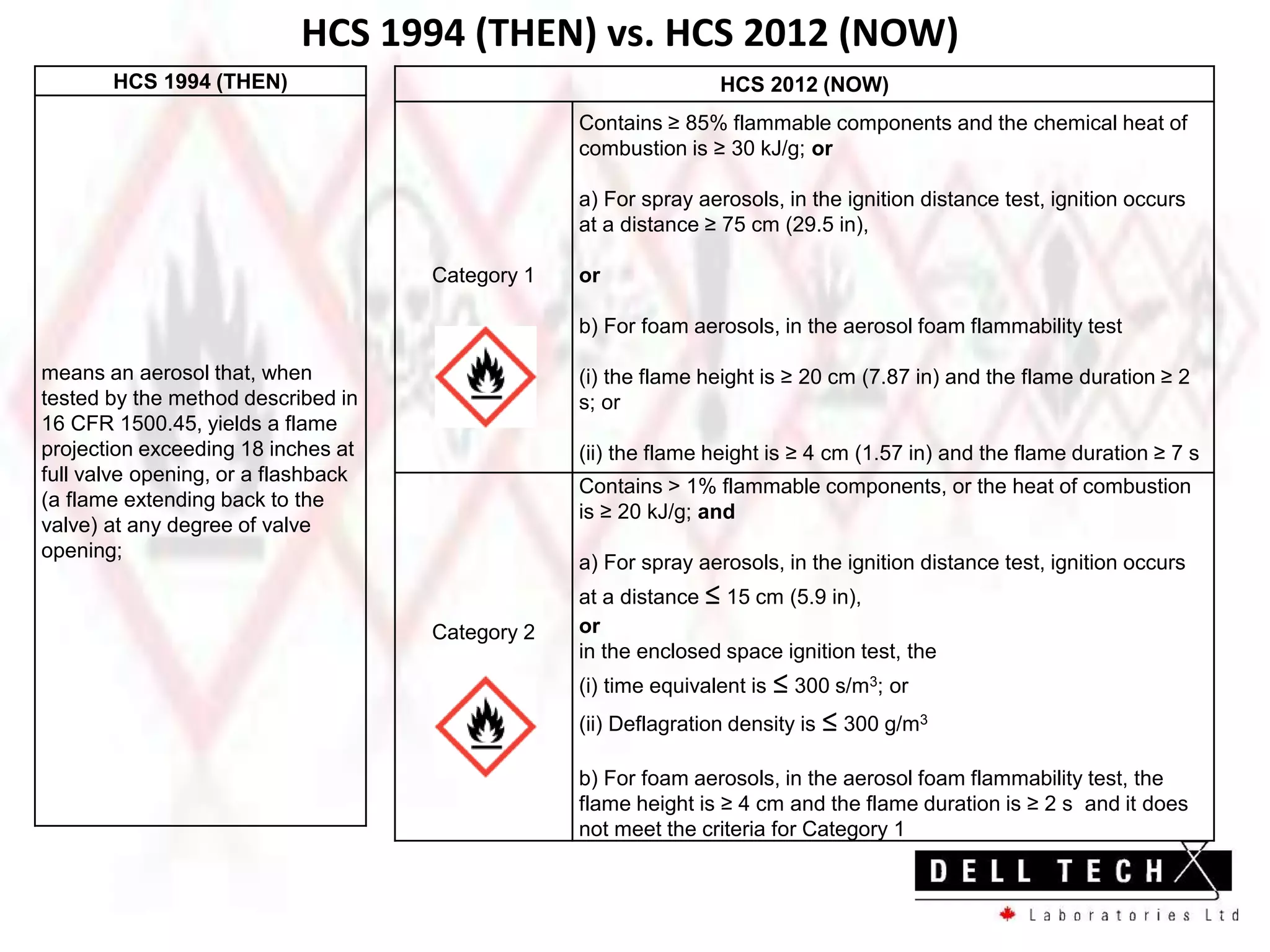

The document discusses the evolution of flammable aerosol testing under HCS regulations from 1994 to 2012, highlighting changes in criteria for categorizing aerosols based on flammability. It details testing methods, including the ignition distance test for spray and foam aerosols, and emphasizes safety considerations. Additionally, it compares the testing equipment and procedures of the past with current standards, providing a comprehensive overview of the necessary steps for compliance and safety evaluation.

![1. Can be tested using ASTM D240-02, ISO 13943, NFPA 30B

2. Calculated as a weighted sum of the individual components.

n

ΔHc (product) = ∑ [wi% × ΔHc(i)]

i

Literature data available from: NFPA 30B, NIST, CRC, Perry’s Chemical

Engineers Handbook, etc.

Heat of Combustion (ΔHc)](https://image.slidesharecdn.com/aerosolflammablitytesting-aerosol101-190716182729/75/Aerosol-Flammability-Testing-for-HCS-2012-GHS-4-2048.jpg)