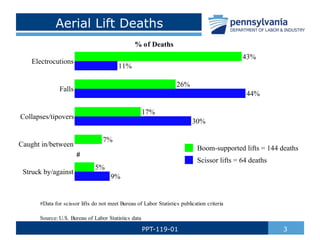

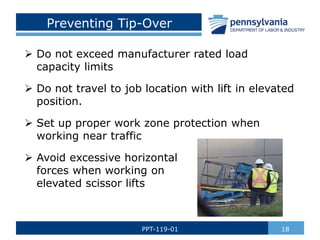

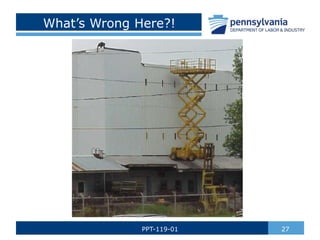

The document outlines safety training requirements for the operation of aerial work platforms, including operator training, inspection protocols, and safety operations to prevent accidents. It presents statistics on fatalities, emphasizing the importance of understanding hazards such as falls, tip-overs, and electrocutions, and mandates proper use and maintenance of the equipment. Specific guidance is provided on safety measures and inspections to mitigate risks associated with different types of aerial lifts.