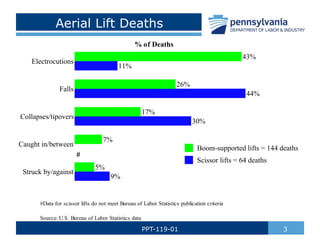

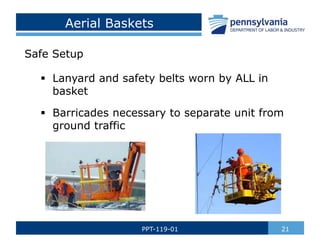

This document provides an overview of aerial work platform safety. It discusses operator training requirements, inspection procedures, safety practices for operating aerial lifts and scissor lifts, fall protection requirements, and tips for preventing electrocutions and tip-overs. The main points covered are the importance of operator training, inspecting equipment before each use, following safe operating procedures, using fall restraint systems for certain lifts, avoiding overhead power lines, and not exceeding load limits or driving on uneven surfaces when elevated.