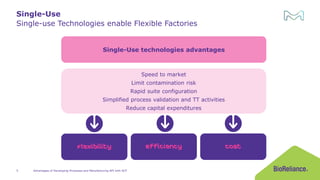

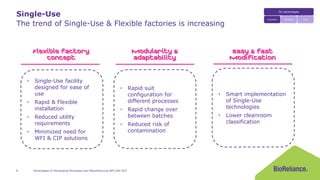

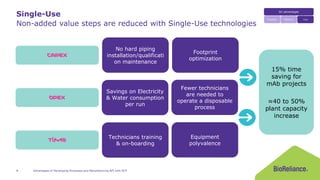

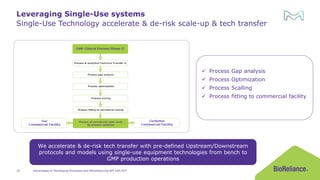

The document discusses the benefits of single-use technologies (SUT) in the pharmaceutical manufacturing sector, emphasizing advantages such as flexibility, efficiency, cost reduction, and lower contamination risk. It highlights how SUT can accelerate tech transfer and improve overall plant efficiency by minimizing non-value-added steps and optimizing resources. The trends and case studies presented demonstrate the increasing adoption of single-use and flexible factory concepts in life sciences manufacturing.