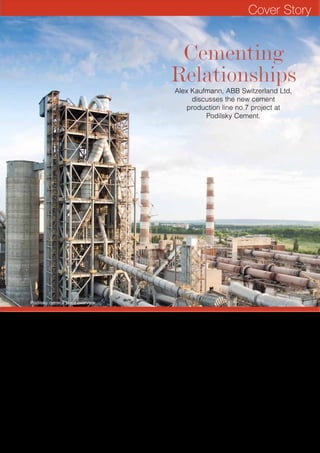

ABB improved the production process at Podilsky Cement's plant in Ukraine by installing integrated electrical, control and automation systems for their new production line no. 7. The new line has a production capacity of 7,500 tons per day, making it the largest cement production line in Ukraine. ABB provided professional support from the design phase through commissioning of the new line. Podilsky Cement and ABB have established a strong partnership through multiple successful automation projects.