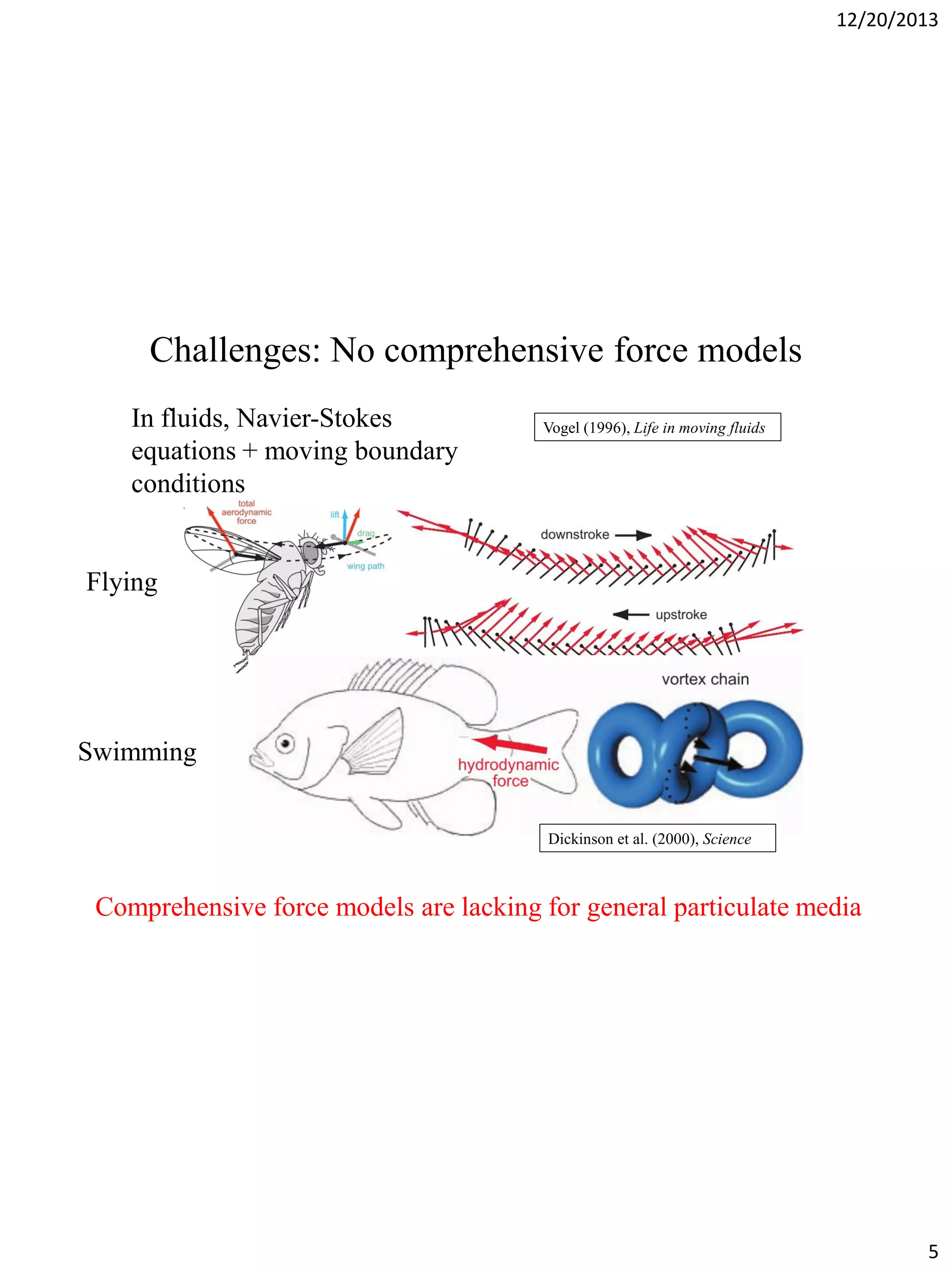

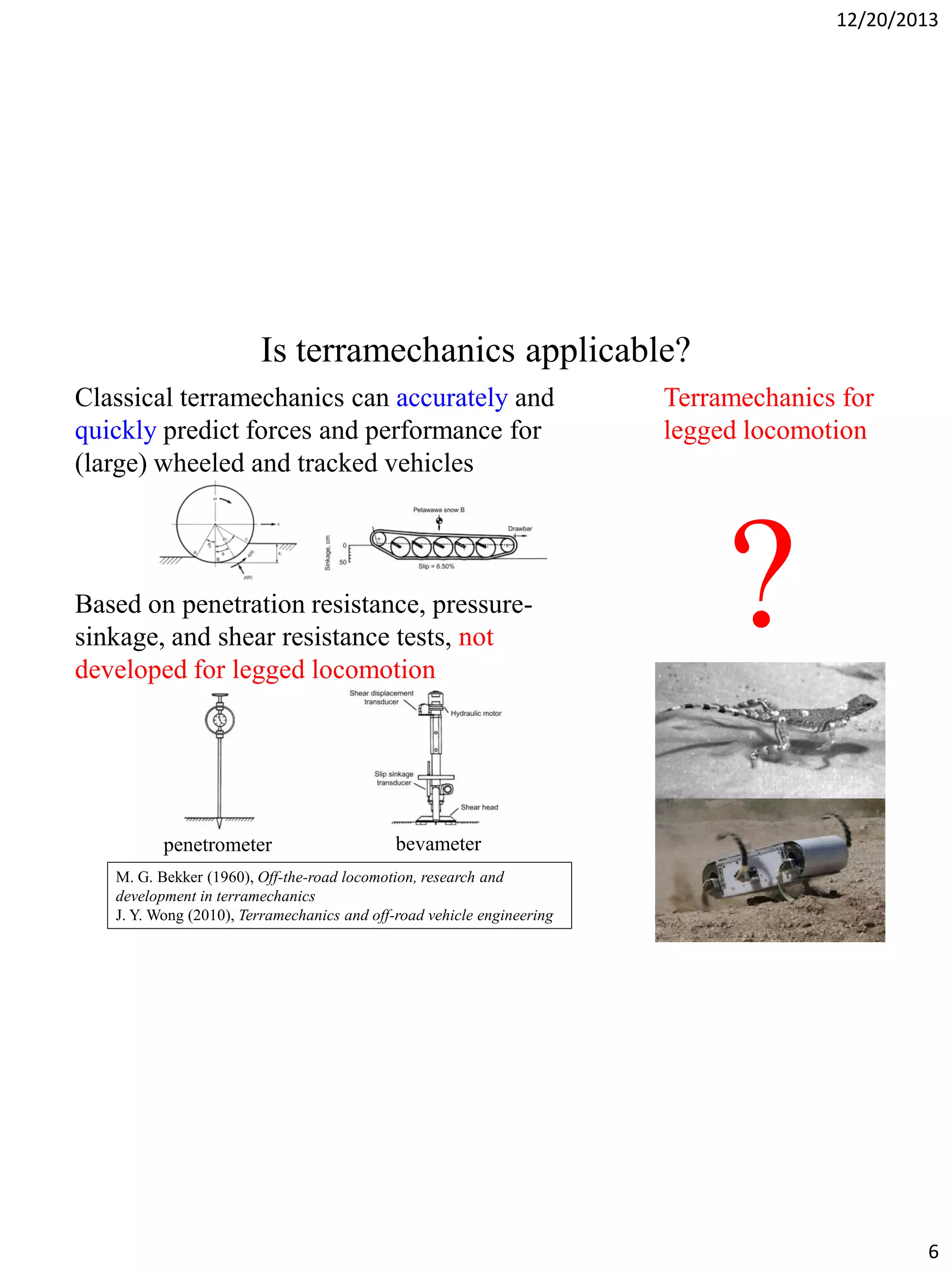

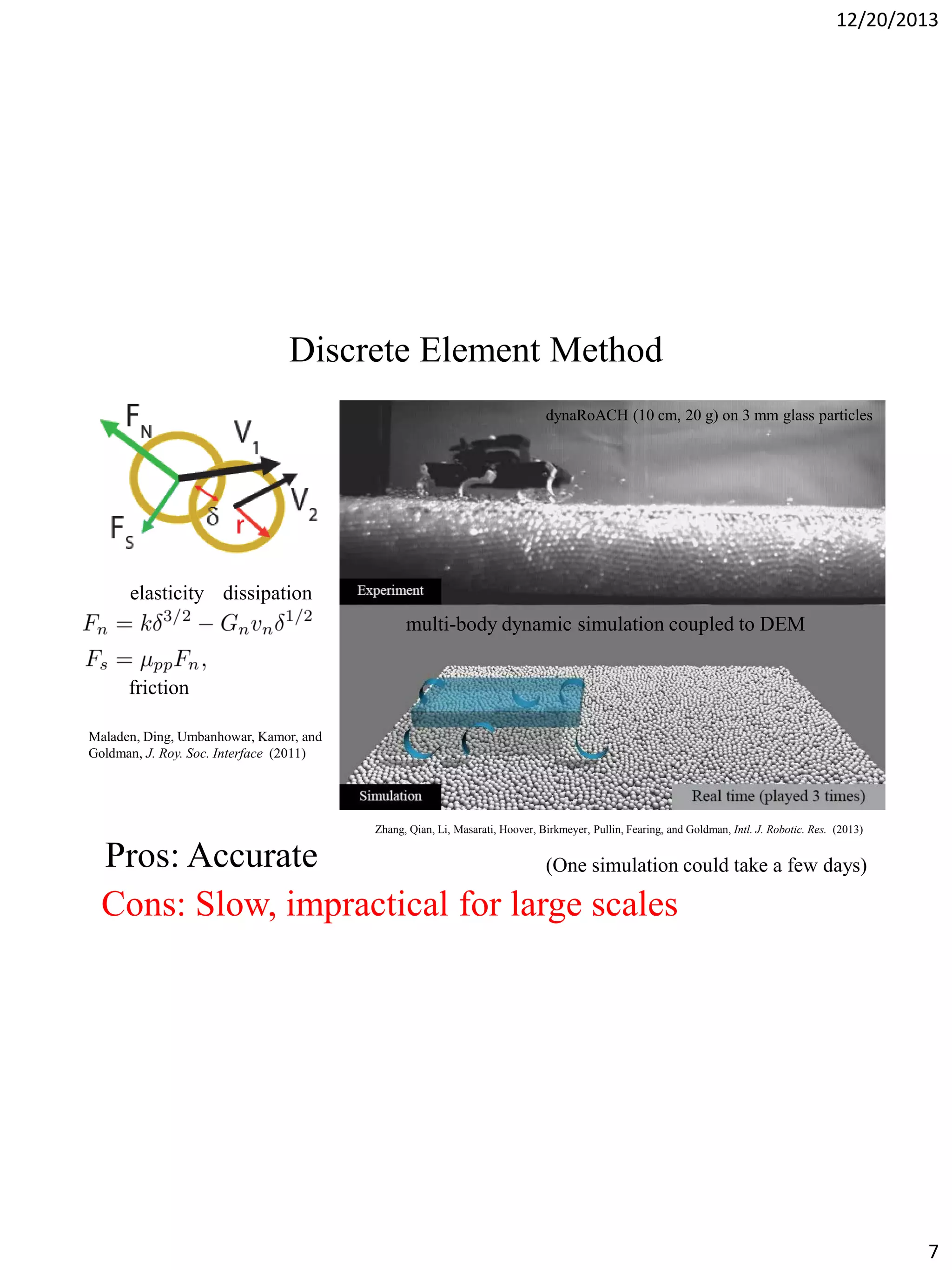

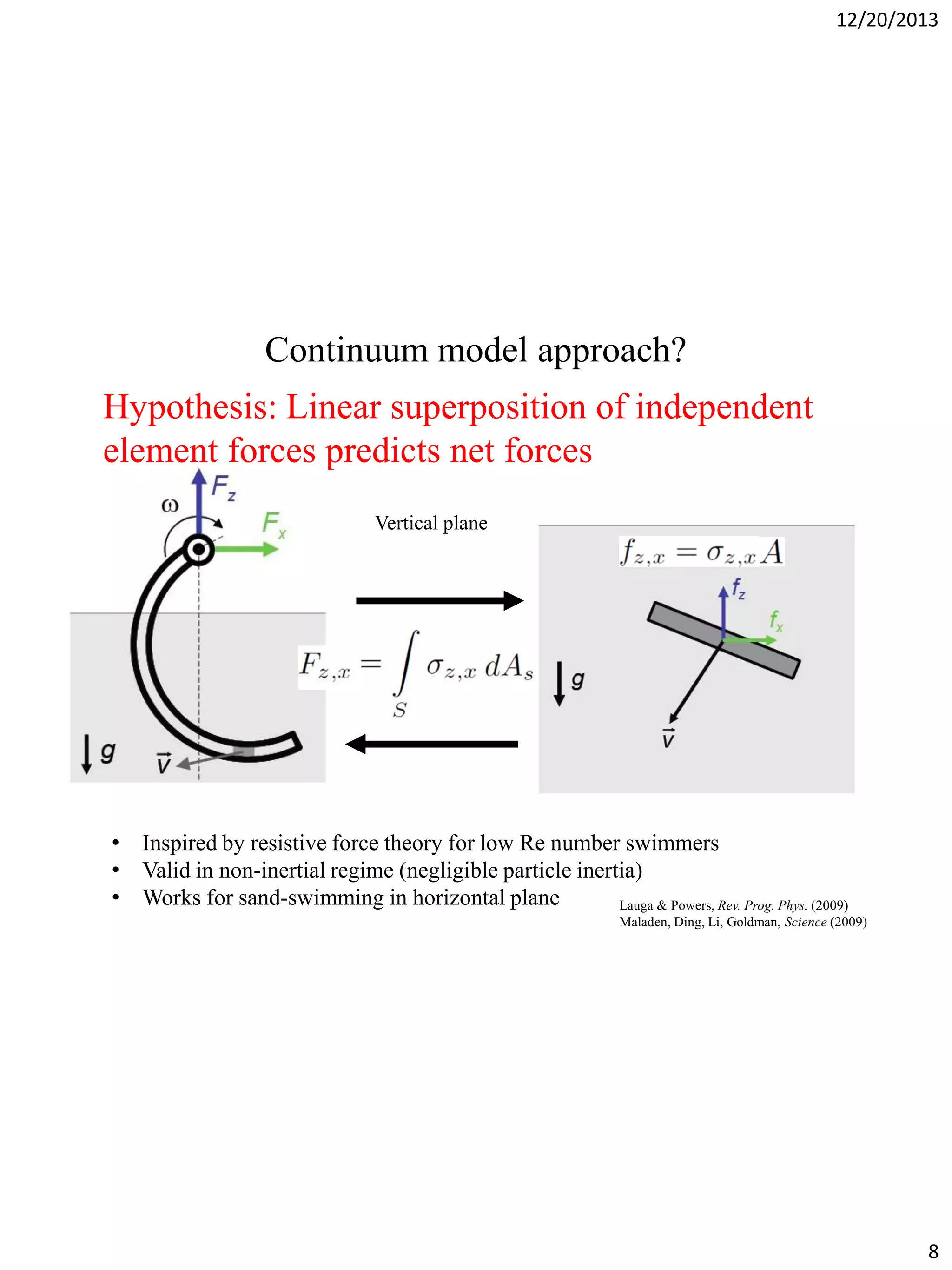

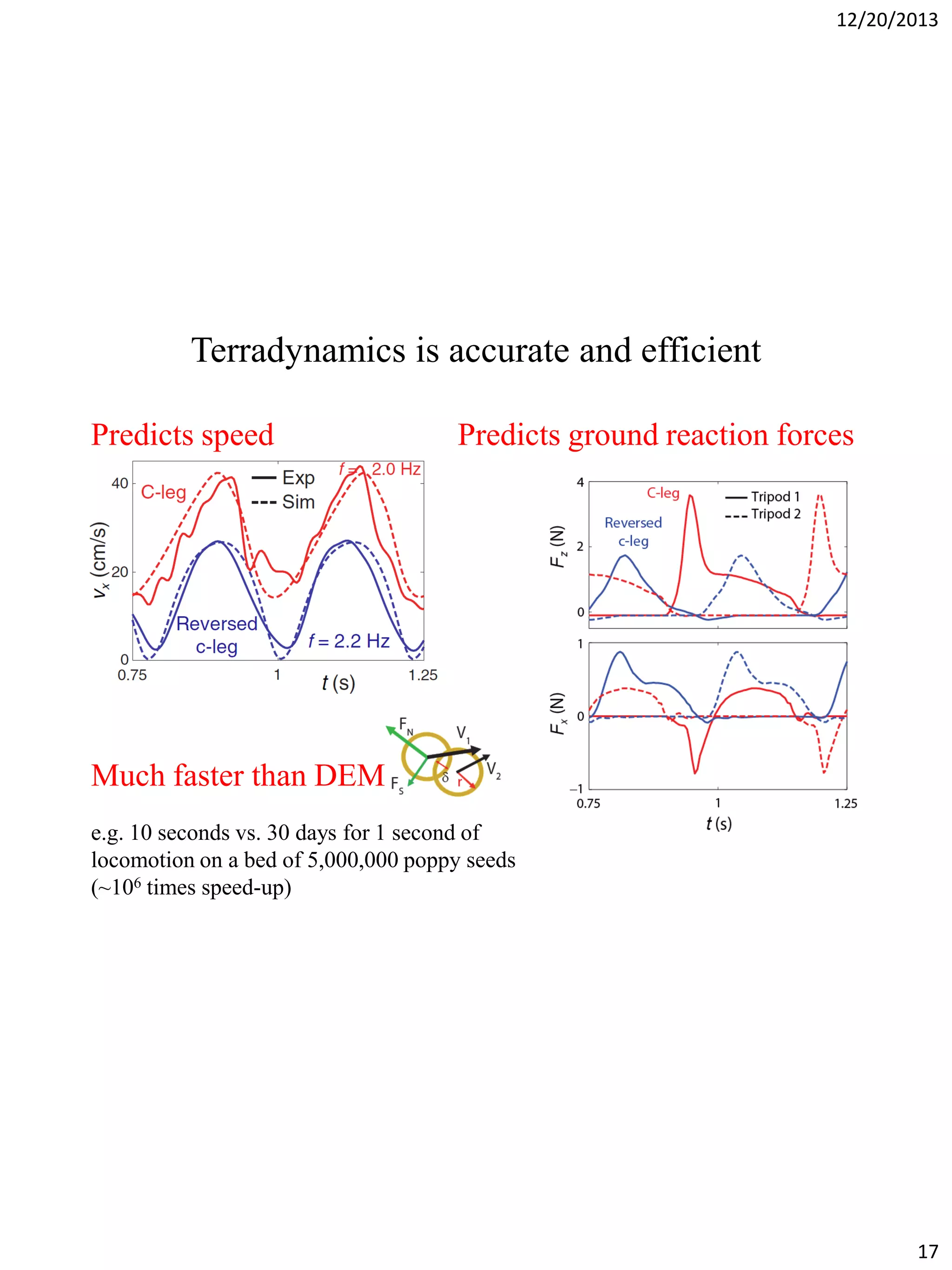

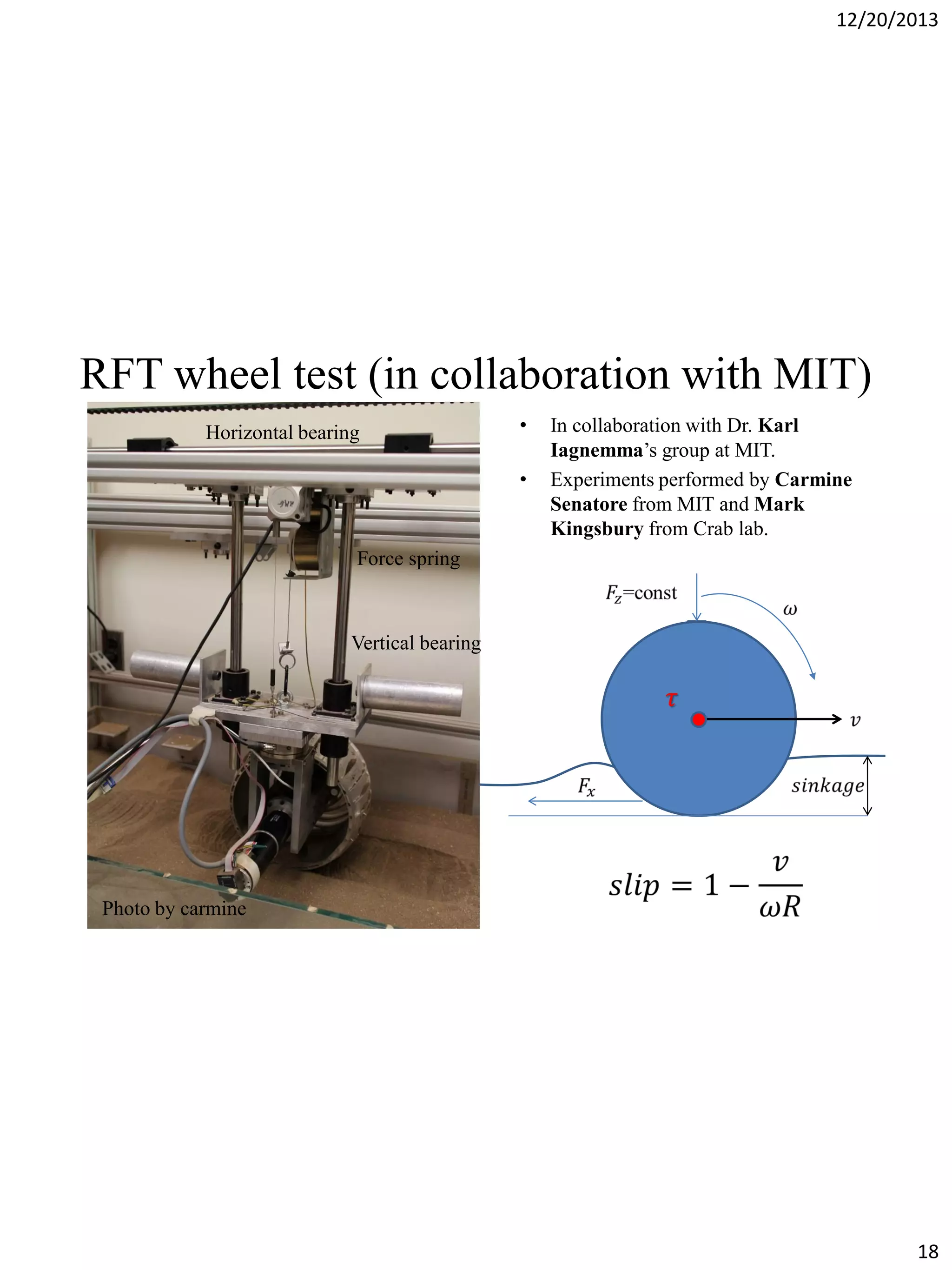

The document discusses terradynamics for legged locomotion on granular media, addressing the challenges posed by granular substrates and the complexity of limb-ground interactions. It presents a resistive force model that predicts locomotion performance without fitting parameters and compares various simulation methods, including discrete element methods and multi-body dynamics. The findings suggest that the resistive force model is effective and much faster than traditional methods for predicting performance in granular environments.

![12/20/2013

Wheels and testing conditions

McMaster

Small

McMaster

Large

3D Printed

MIT Smooth

Diameter [mm]

152.4

203.2

145 (to lug tips)

260

Width [mm]

44.5

50.8

76.2

160

Fz Tested [N]

7

20

10, 18

60, 120

Loose

Loose and

Compact

Loose and compact

(only for 18 N)

Loose and

Compact

Terrain State Tested

(Poppy seeds)

McMaster

Small

McMaster

Large

3D Printed

MIT Smooth (approx. to scale)

20](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-20-2048.jpg)

![12/20/2013

Drawbar vs. slip ratio in experiment and model

Experiment

WR

RFT

10

Drawbar [N]

5

0

-5

-0.5

0

0.5

Slip

21](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-21-2048.jpg)

![12/20/2013

Experiment

WR

RFT

10

3D Printed

Fz = 18 N

Compact

Drawbar [N]

5

0

-5

-0.5

0

0.5

Slip

0.8

25

Sinkage [mm]

Torque [Nm]

0.6

0.4

0.2

15

10

0

-0.2

20

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

22](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-22-2048.jpg)

![12/20/2013

Experiment

WR

RFT

6

4

McMaster

Large

Fz = 20 N

Compact

Drawbar [N]

2

0

-2

-4

-6

-8

-10

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Slip

35

1

30

Sinkage [mm]

Torque [Nm]

0.8

0.6

0.4

0.2

25

20

15

0

10

-0.2

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

5

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

23](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-23-2048.jpg)

![12/20/2013

3

McMaster

Small

Fz = 7 N

Loose

Experiment

WR

RFT

2

Drawbar [N]

1

0

-1

-2

-3

-4

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Slip

0.3

30

0.25

25

Sinkage [mm]

Torque [Nm]

0.2

0.15

0.1

0.05

0

20

15

10

-0.05

-0.5

0

Slip

0.5

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

27](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-27-2048.jpg)

![12/20/2013

Drawbar [N]

5

Experiment

WR

RFT

McMaster

Large

Fz = 20 N

Loose

0

-5

-10

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

1.2

50

1

Sinkage [mm]

Torque [Nm]

0.8

0.6

0.4

0.2

40

30

20

0

10

-0.2

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Slip

28](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-28-2048.jpg)

![12/20/2013

Experiment

WR

RFT

6

4

McMaster

Large

Fz = 20 N

Compact

Drawbar [N]

2

0

-2

-4

-6

-8

-10

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Slip

35

1

30

Sinkage [mm]

Torque [Nm]

0.8

0.6

0.4

0.2

25

20

15

0

10

-0.2

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

5

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

29](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-29-2048.jpg)

![12/20/2013

3

Experiment

WR

RFT

2

Drawbar [N]

1

3D Printed

Fz = 10 N

Loose

0

-1

-2

-3

-4

-5

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

Slip

25

0.4

Sinkage [mm]

20

Torque [Nm]

0.3

0.2

0.1

15

10

0

-0.1

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

-0.5

0

0.5

Slip

30](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-30-2048.jpg)

![12/20/2013

Experiment

WR

RFT

Drawbar [N]

5

3D Printed

Fz = 18 N

Loose

0

-5

-10

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

35

30

Sinkage [mm]

Torque [Nm]

0.6

0.4

0.2

25

20

15

0

10

-0.2

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

-0.5

0

0.5

Slip

31](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-31-2048.jpg)

![12/20/2013

Experiment

WR

RFT

10

3D Printed

Fz = 18 N

Compact

Drawbar [N]

5

0

-5

-0.5

0

0.5

Slip

0.8

25

Sinkage [mm]

Torque [Nm]

0.6

0.4

0.2

15

10

0

-0.2

20

-0.6 -0.4 -0.2

0

Slip

0.2

0.4

0.6

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

32](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-32-2048.jpg)

![12/20/2013

30

Experiment L

Experiment C

WR L

WR C

RFT L

RFT C

Drawbar [N]

20

10

0

MIT Wheel

Fz = 60 N

Compact/Loose

-10

-20

-30

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

50

Slip

4

40

Sinkage [mm]

Torque [Nm]

3

2

1

0

30

20

10

-1

-0.5

0

Slip

0.5

-0.6 -0.4 -0.2

0

0.2

0.4

0.6

Slip

33](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-33-2048.jpg)

![12/20/2013

Experiment L

Experiment C

WR L

WR C

RFT L

RFT C

40

Drawbar [N]

20

0

MIT Wheel

Fz = 120 N

Compact/Loose

-20

-40

-60

-0.6 -0.4 -0.2

0

0.2

0.4

8

60

50

Sinkage [mm]

6

Torque [Nm]

0.6

Slip

4

2

40

30

20

0

10

-2

-0.6 -0.4 -0.2

-0.5

0

0.5

0

0.2

0.4

0.6

Slip

Slip

34](https://image.slidesharecdn.com/paper809600-140205164101-phpapp02/75/A-Terradynamics-for-Legged-Locomotion-on-Granular-Media-34-2048.jpg)