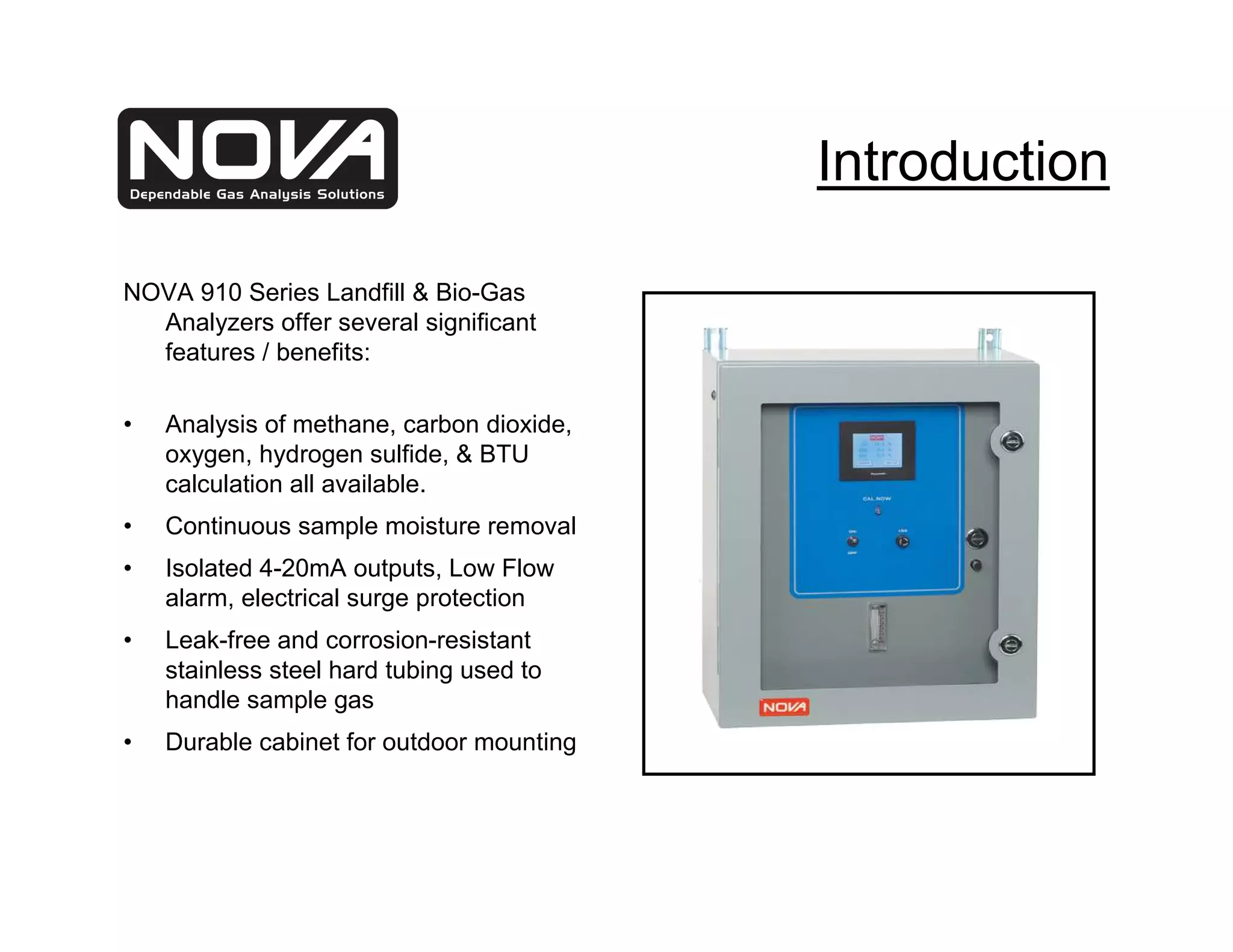

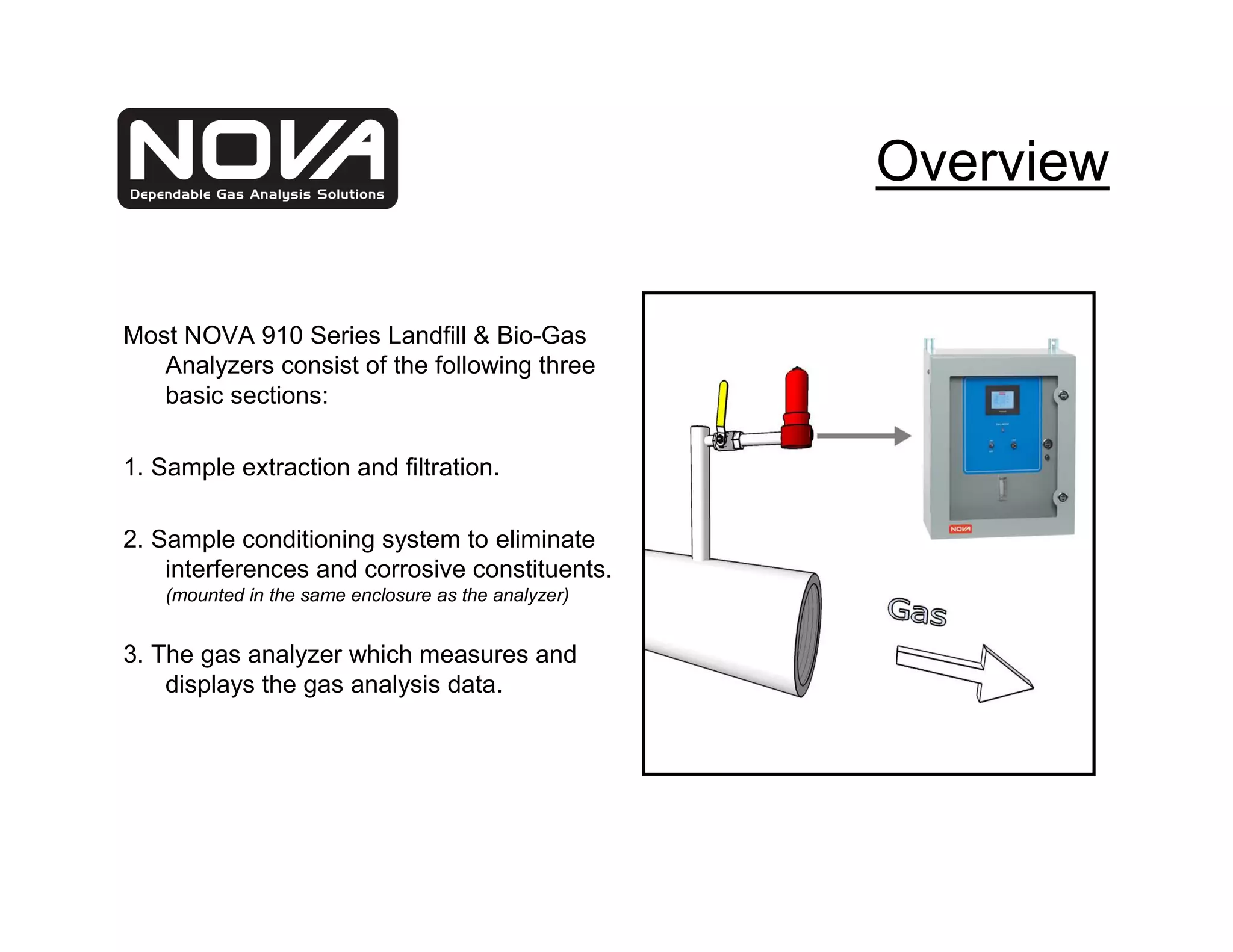

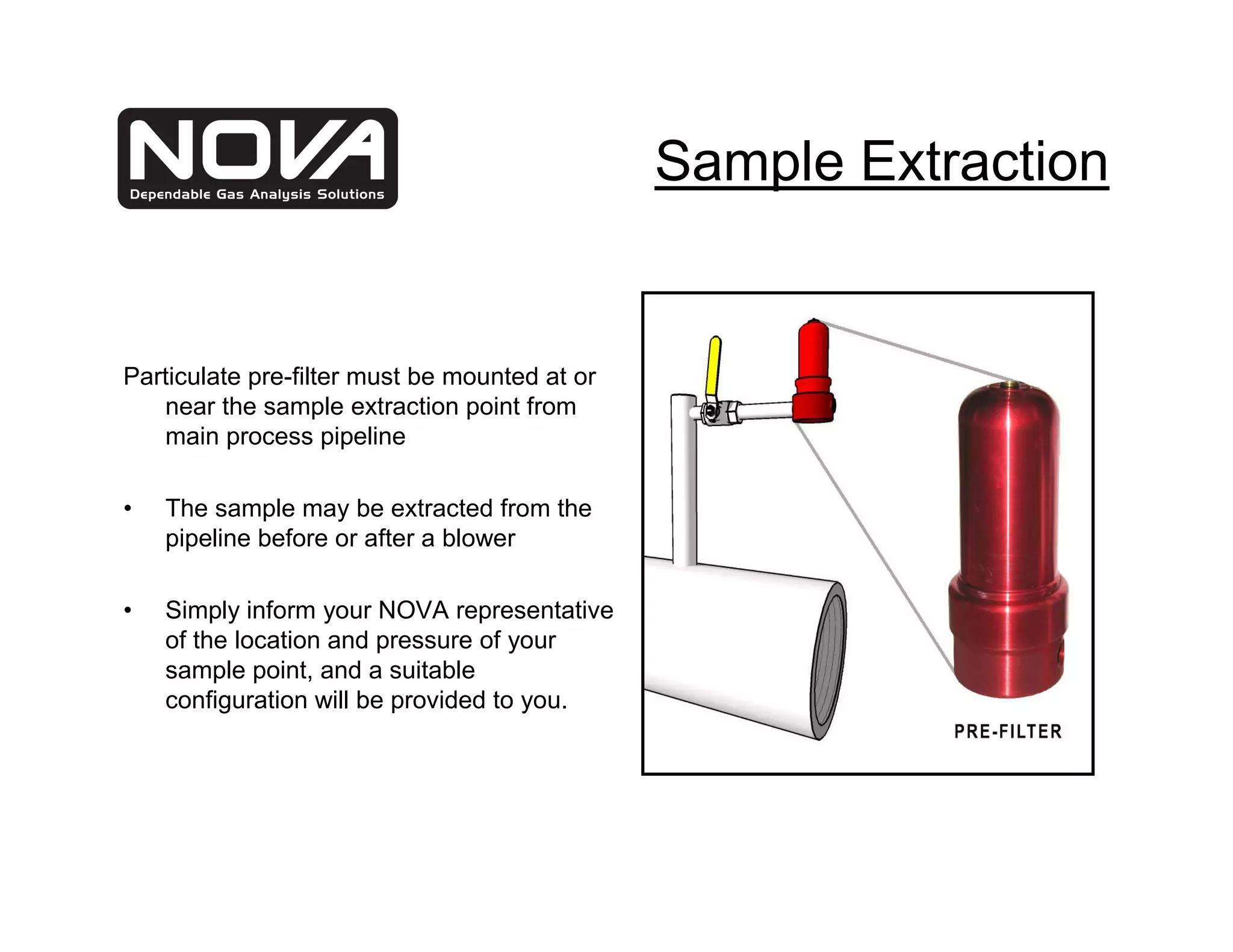

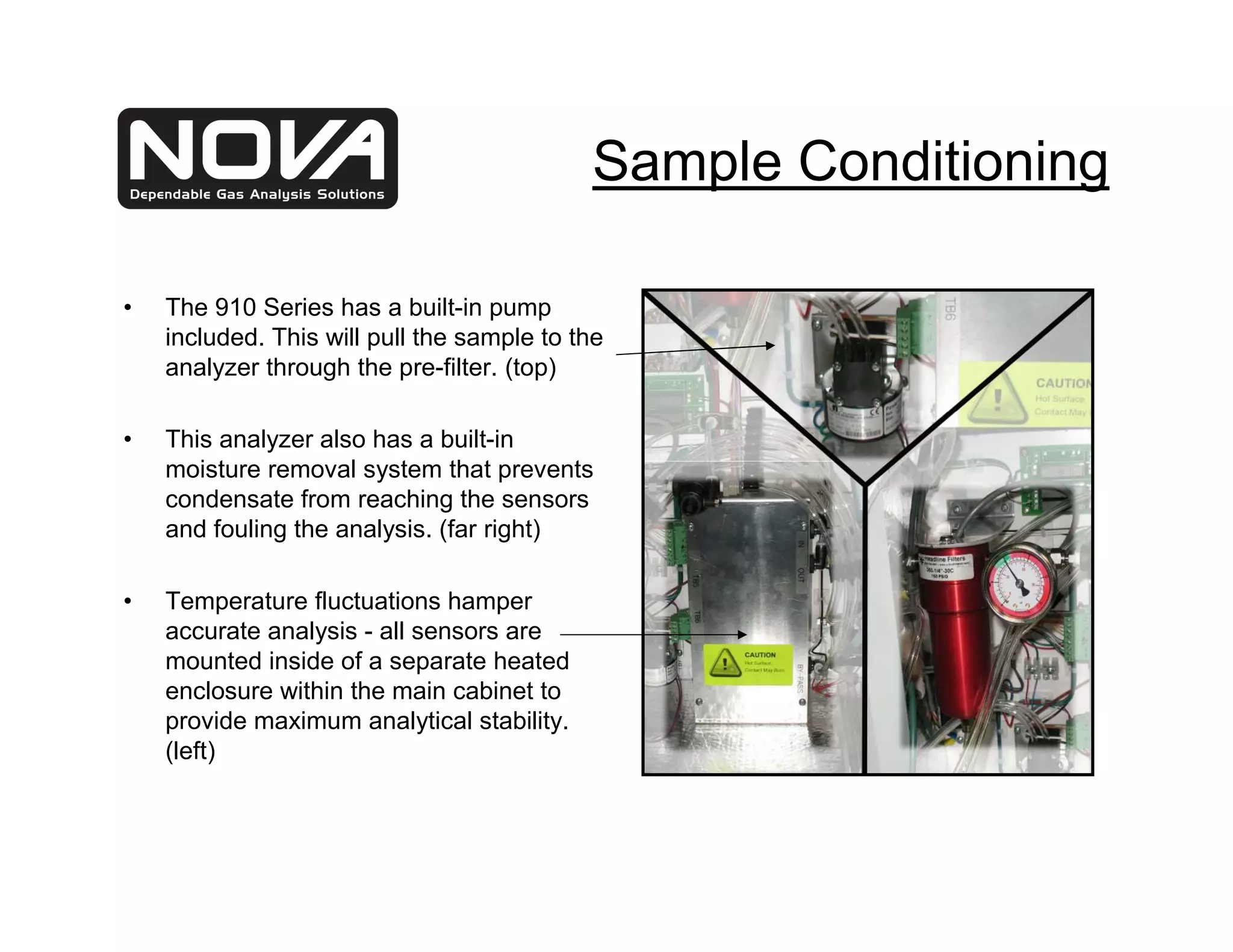

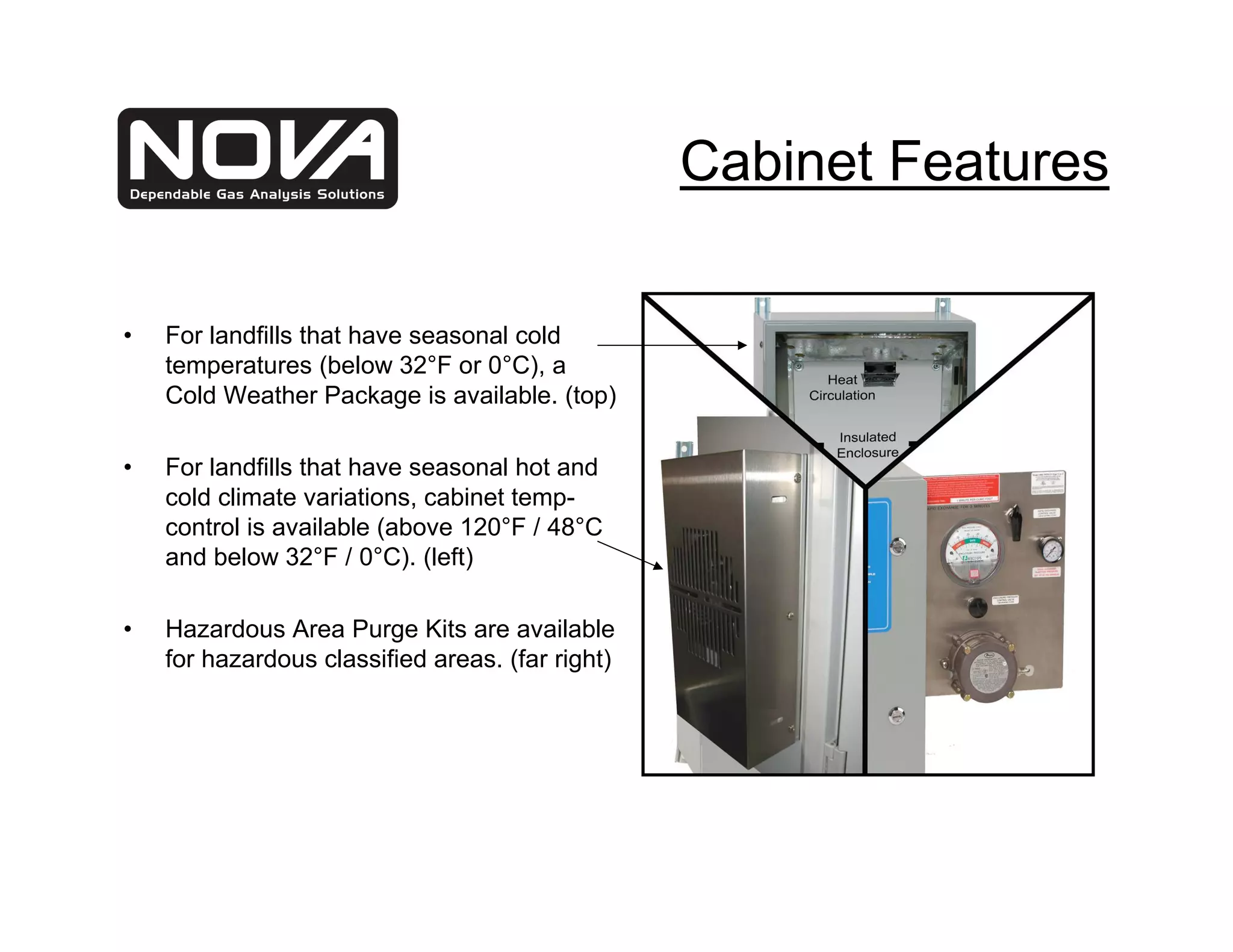

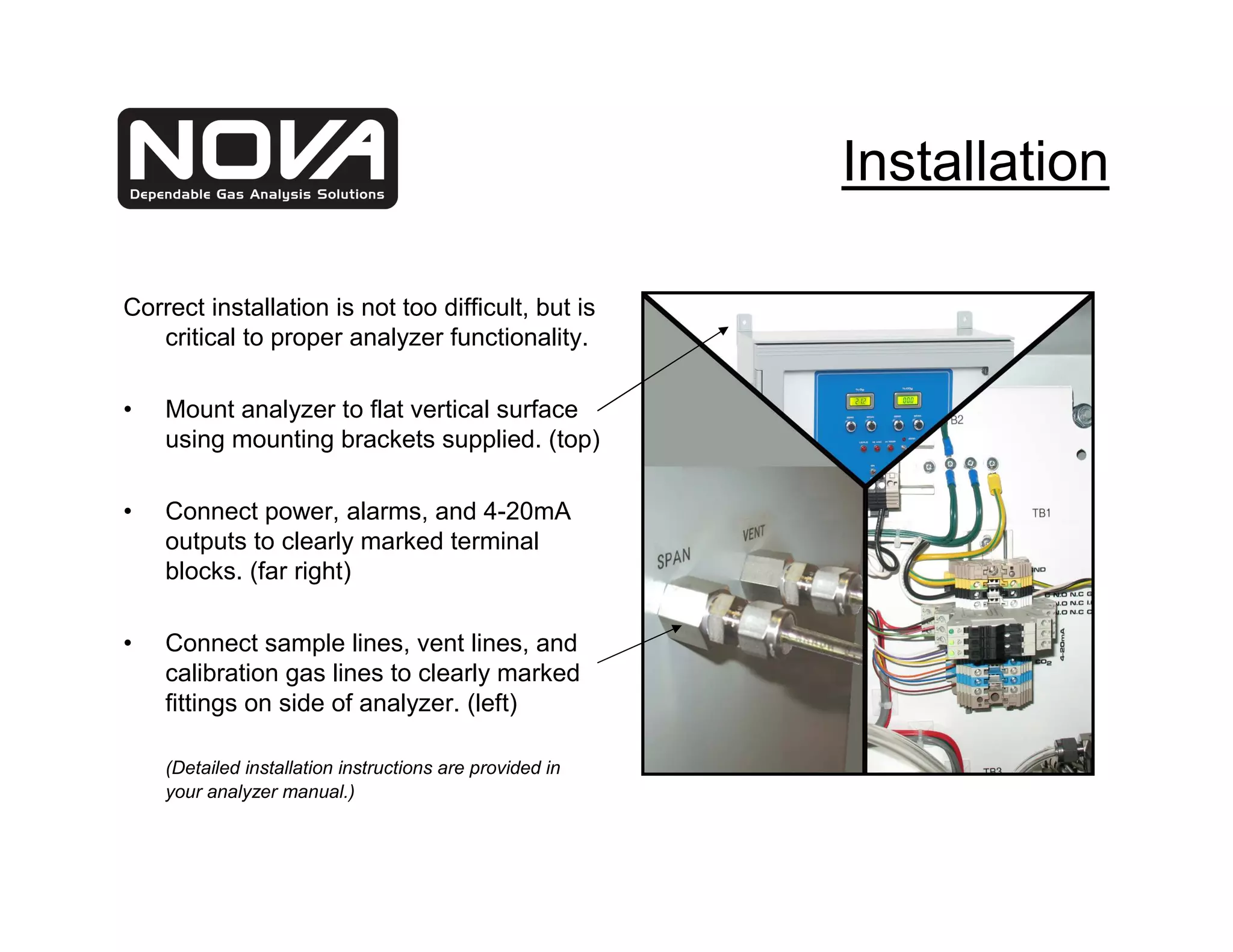

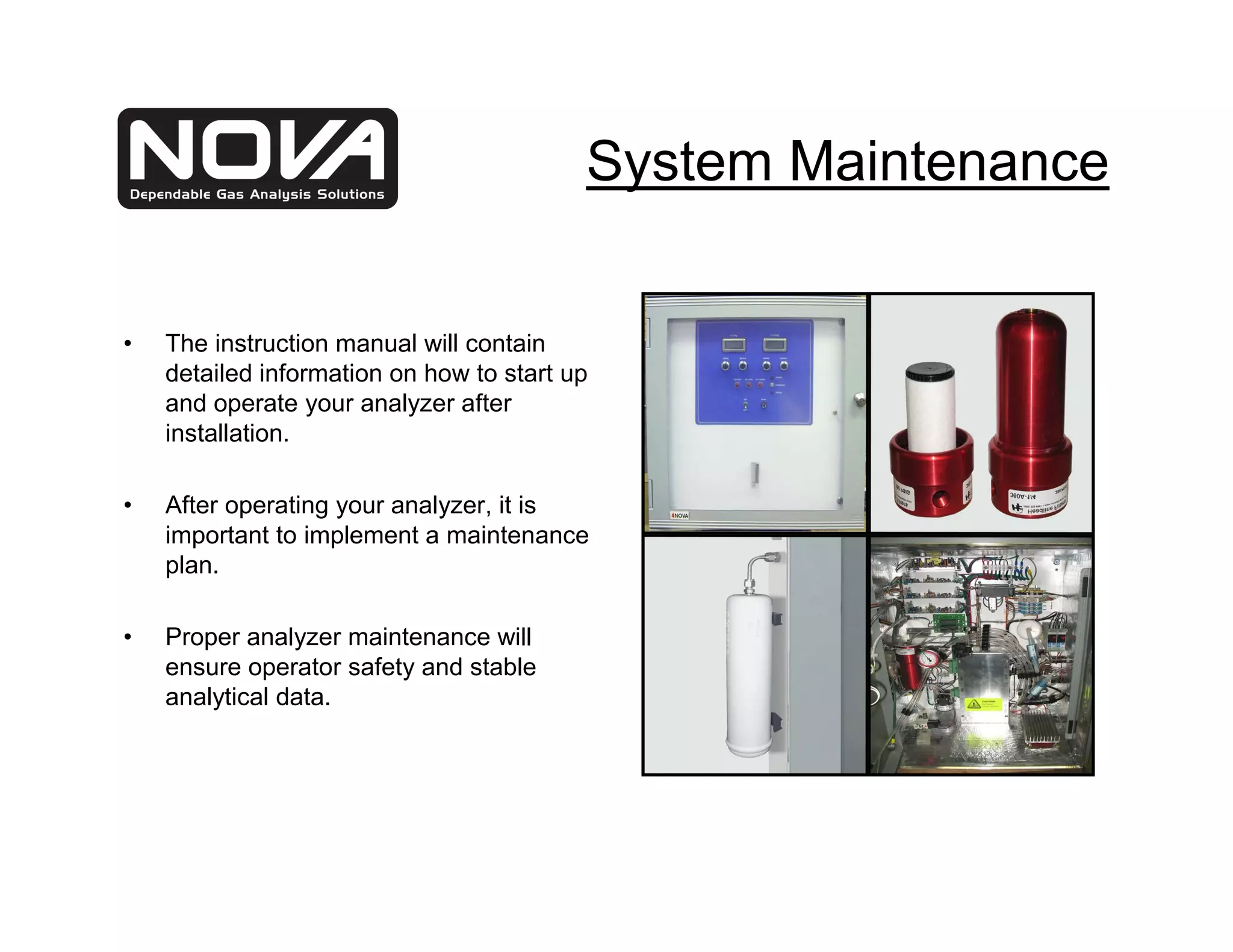

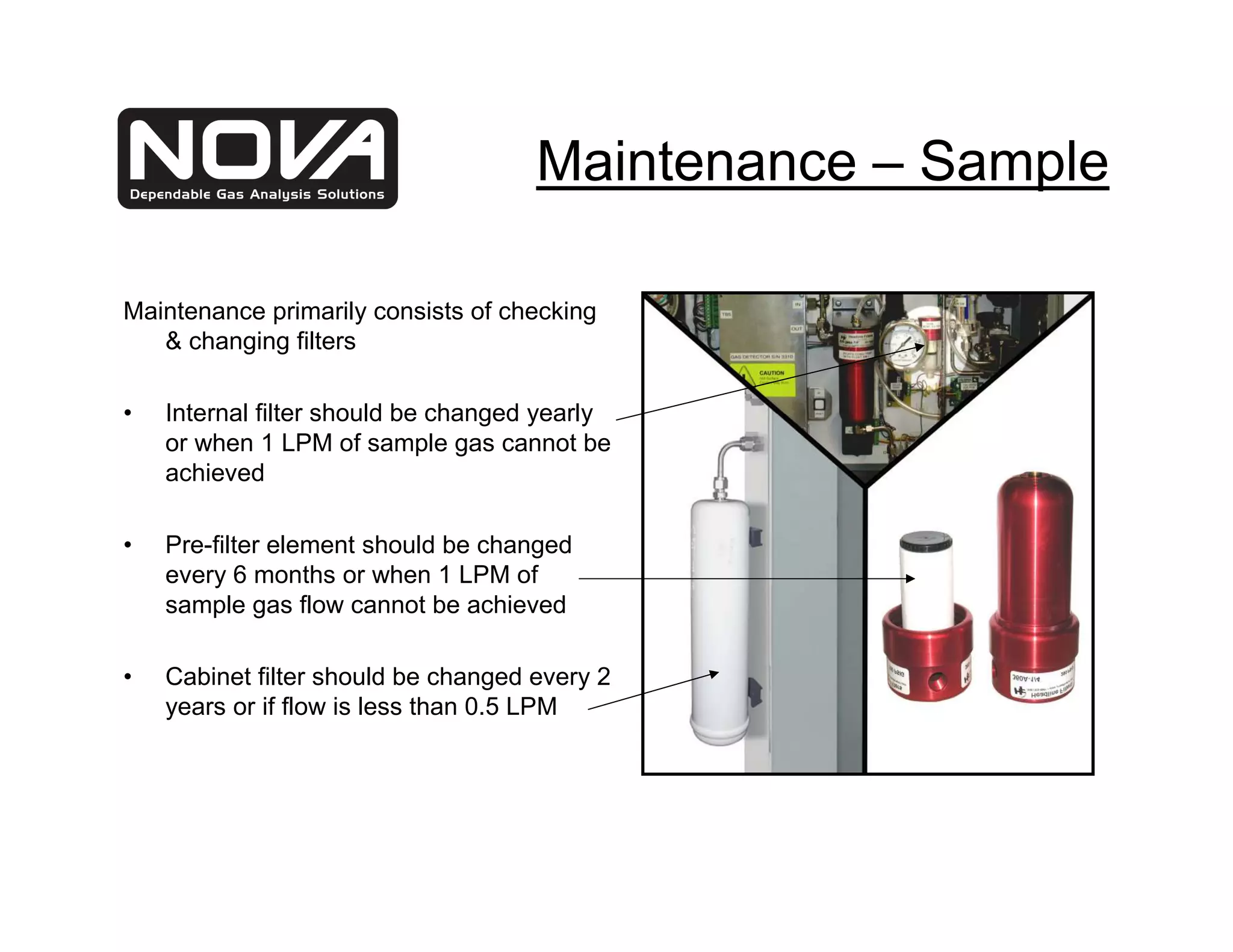

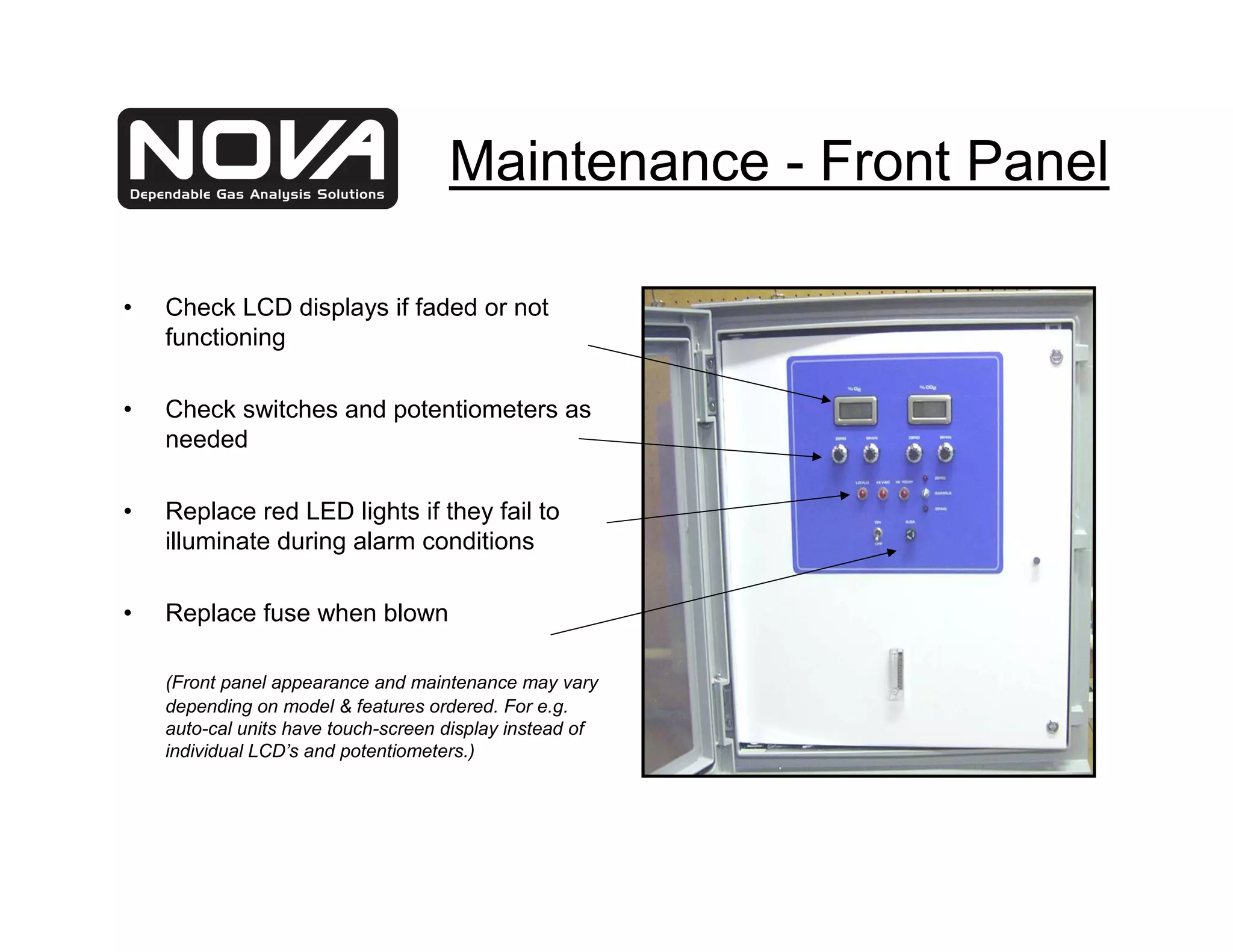

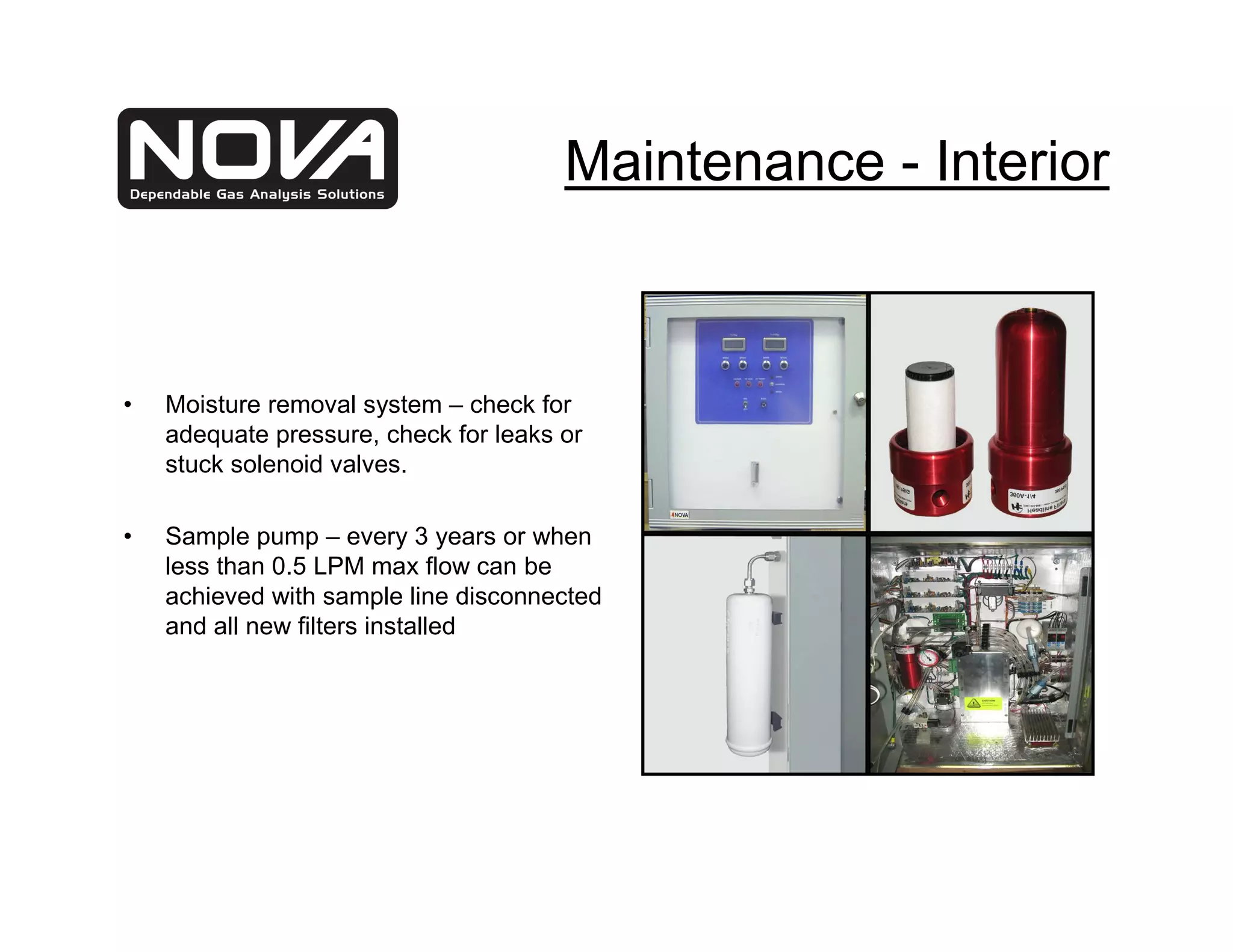

The document provides information on Nova Analytical Systems' 910 Series Continuous Landfill and Bio-Gas Analyzers. It discusses the key features of the analyzers including their ability to analyze multiple gases and continuously remove moisture from samples. It also describes the basic components of the analyzers including sample extraction and conditioning systems, as well as the gas analyzer itself. Finally, it offers recommendations for installation, operation, and preventative maintenance of the analyzers to ensure long life and stable performance.