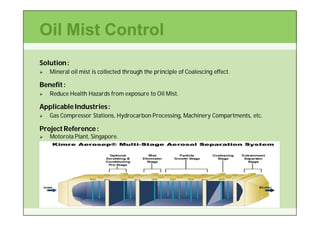

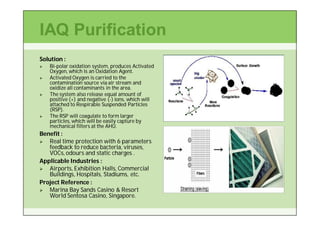

GENMECH Engineering provides clean air solutions for industrial applications. They specialize in air scrubbing, photolytic oxidation using UV-C light and ozone, and bi-polar ionization. They design systems to control industrial corrosion, odors, VOCs, oil mist, and improve indoor air quality. Their solutions help protect facilities, reduce health hazards and emissions, and manage airborne contaminants from various industrial processes.