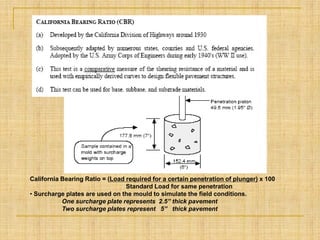

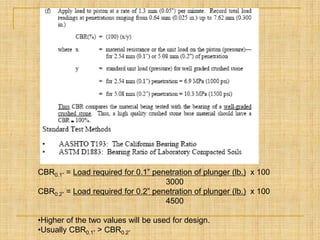

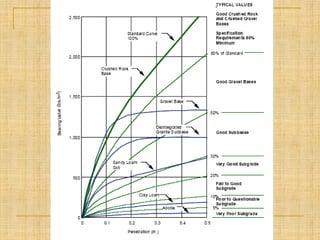

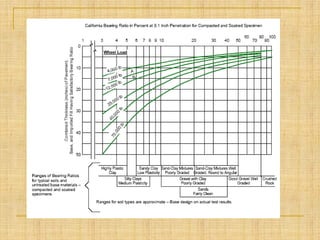

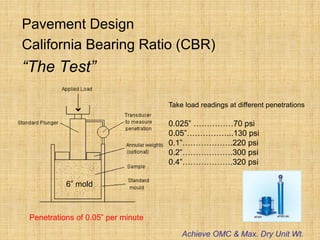

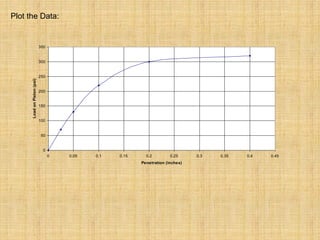

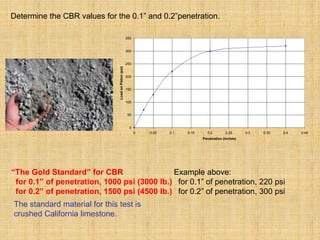

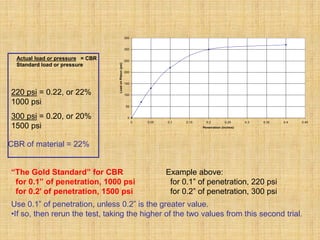

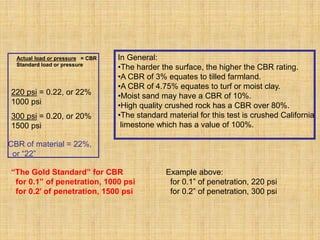

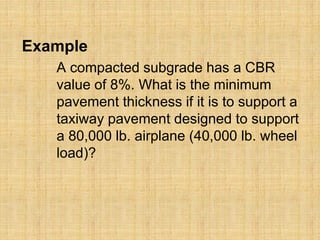

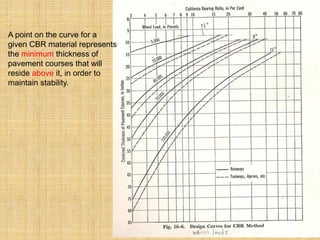

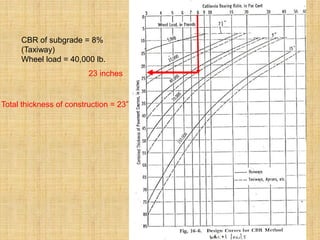

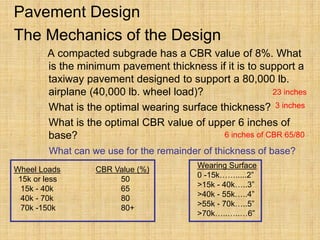

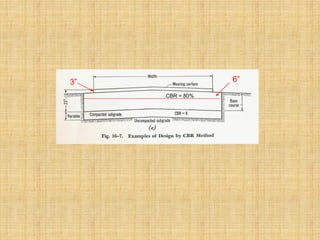

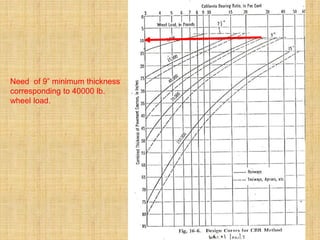

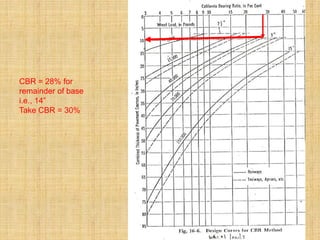

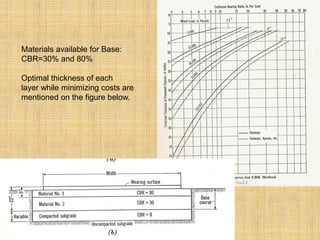

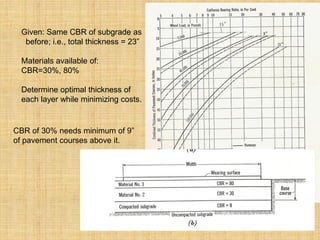

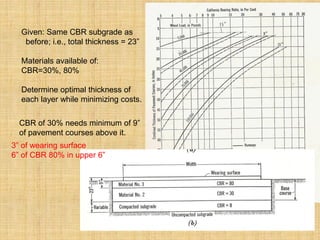

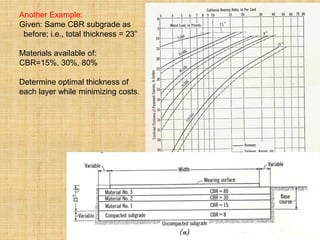

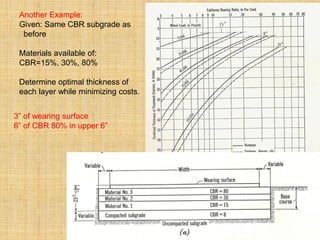

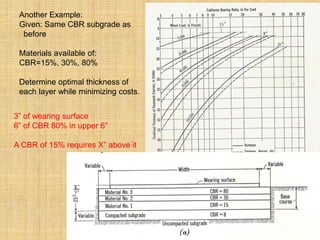

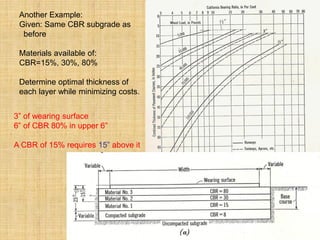

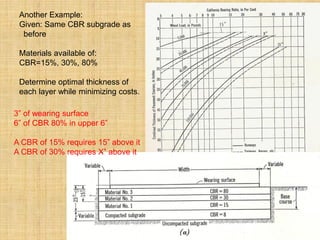

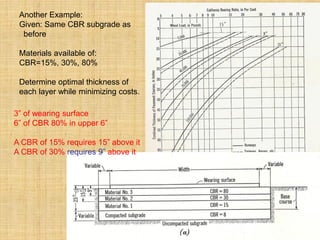

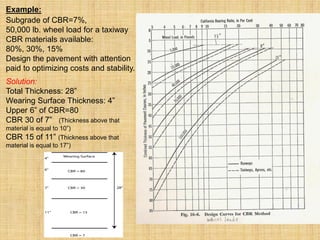

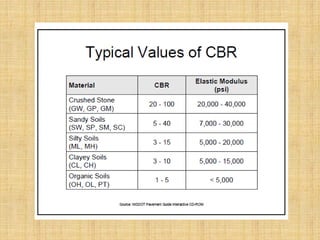

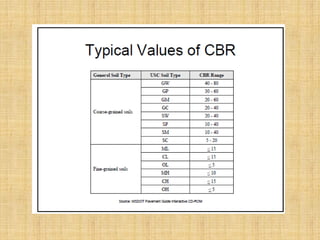

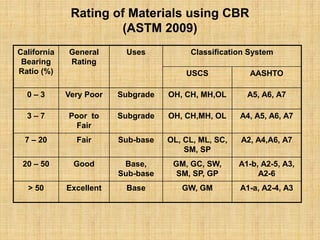

The California Bearing Ratio (CBR) test measures the mechanical strength of soils and pavement materials. It involves measuring the load or pressure required to penetrate a sample with a standard plunger at specific depths. The measured load is divided by the standard load on a crushed rock material to determine the CBR value. Higher CBR values indicate stronger, higher quality materials. CBR tests are used to design pavement structures and determine thicknesses of pavement layers needed to support anticipated traffic loads.