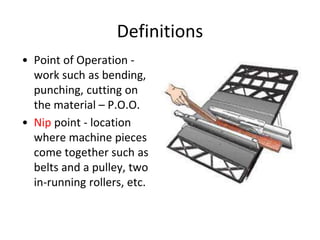

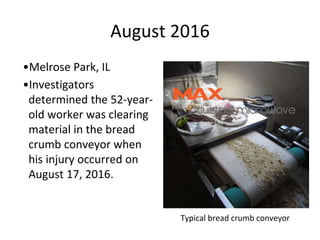

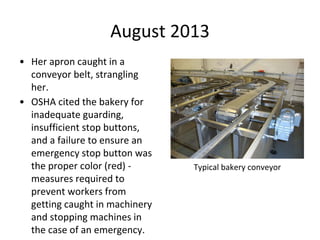

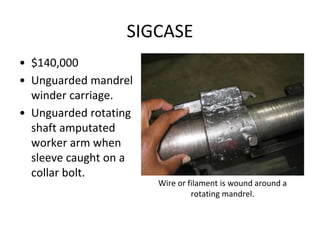

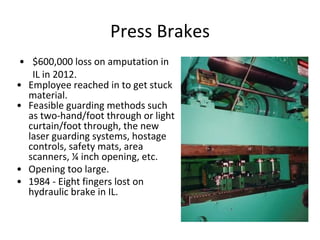

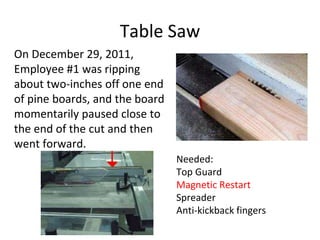

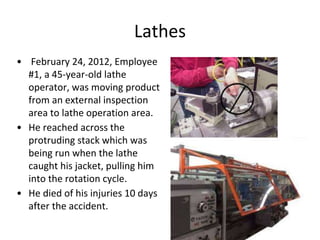

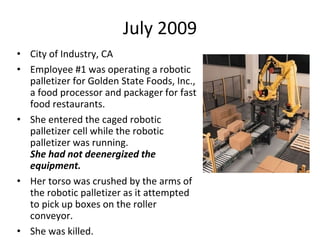

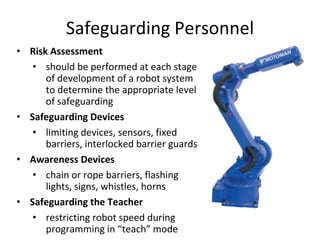

This document provides an overview of machine guarding requirements and hazards. It discusses various types of machine motions and operations that present hazards. It summarizes OSHA regulations regarding guarding requirements for specific machines like power presses, circular saws, lathes, and others. Case studies of injuries and accidents involving unguarded machines are presented to illustrate the importance of compliance. Proper machine guarding principles and methods are outlined to help protect workers from serious injuries like amputations.

![208

225

273

504

1343

219(d)(1)

215(a)(4)

215(b)(9)

212(a)(3)(ii)

212(a)(1)

Machinery & Machine Guarding

[1910.211 – .219]

2

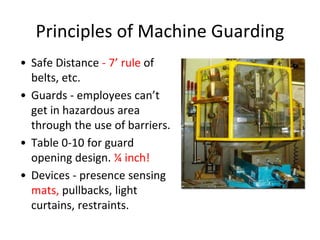

GENERAL REQUIREMENTS– TYPES OF GUARDING METHODS

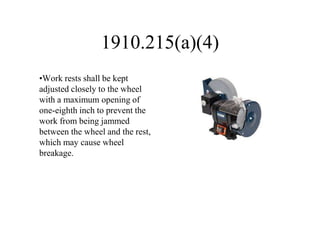

ABRASIVE WHEEL – WORK RESTS

POWER TRANSMISSION – GUARDING FOR PULLEYS

GENERAL REQUIREMENTS – POINT OF OPERATION

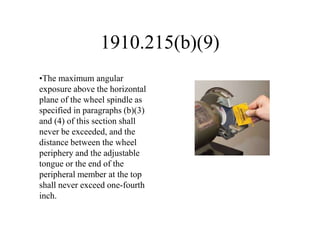

ABRASIVE WHEEL– TONGUE GUARDS

SUBPARTO](https://image.slidesharecdn.com/gimachineguardingandrobotsafety2018511-180725115554/85/511-machine-guarding-2-320.jpg)