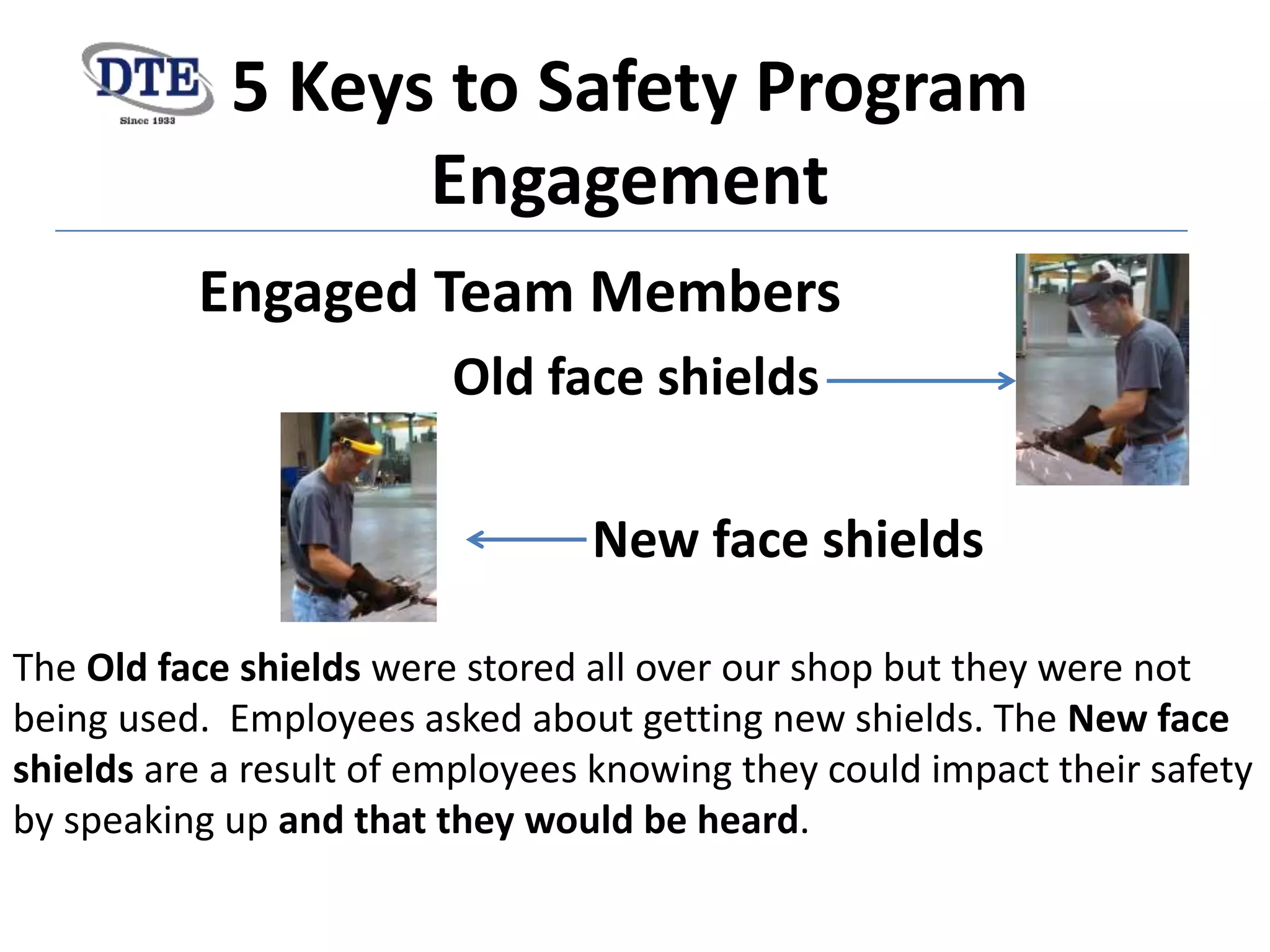

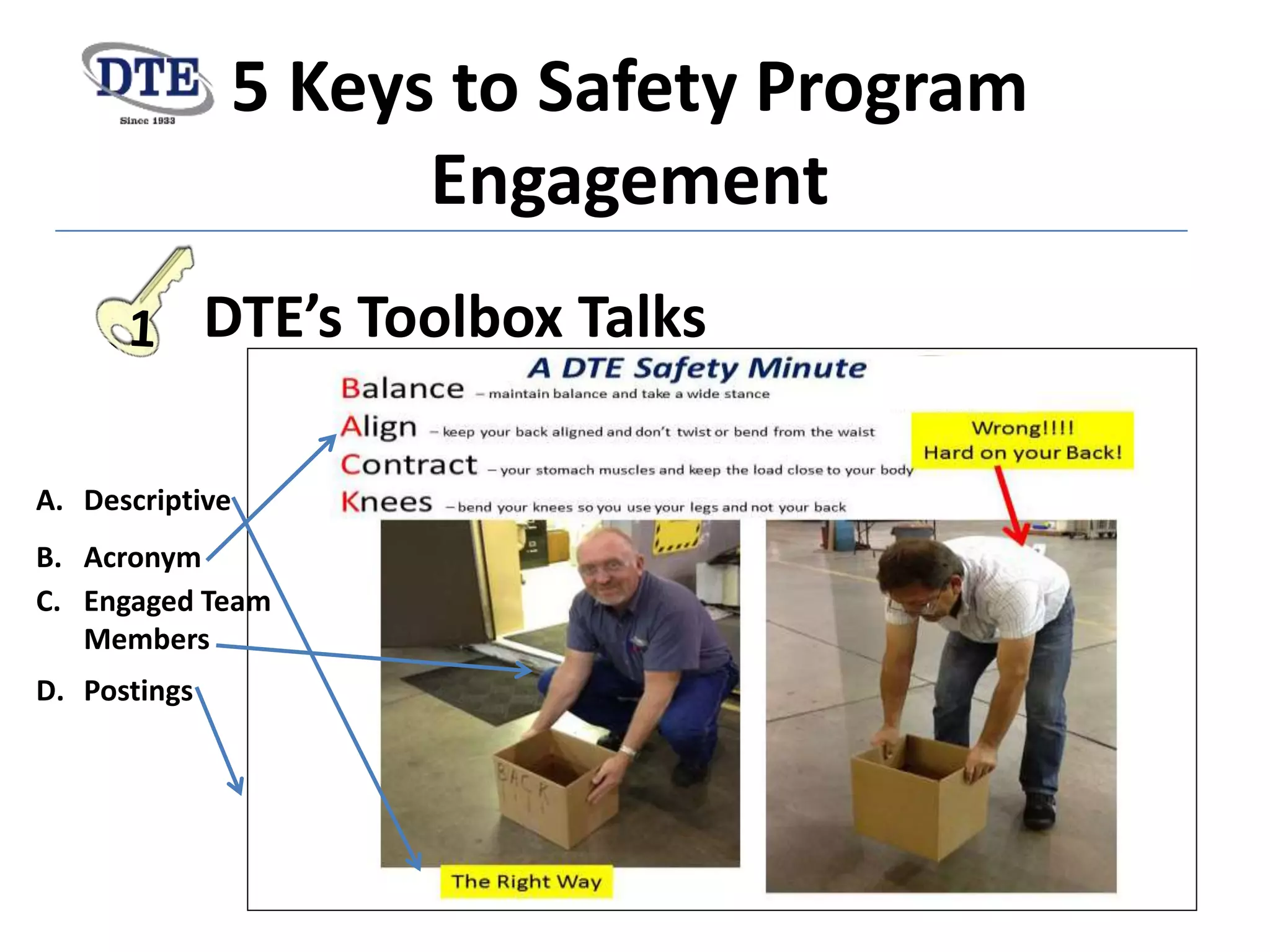

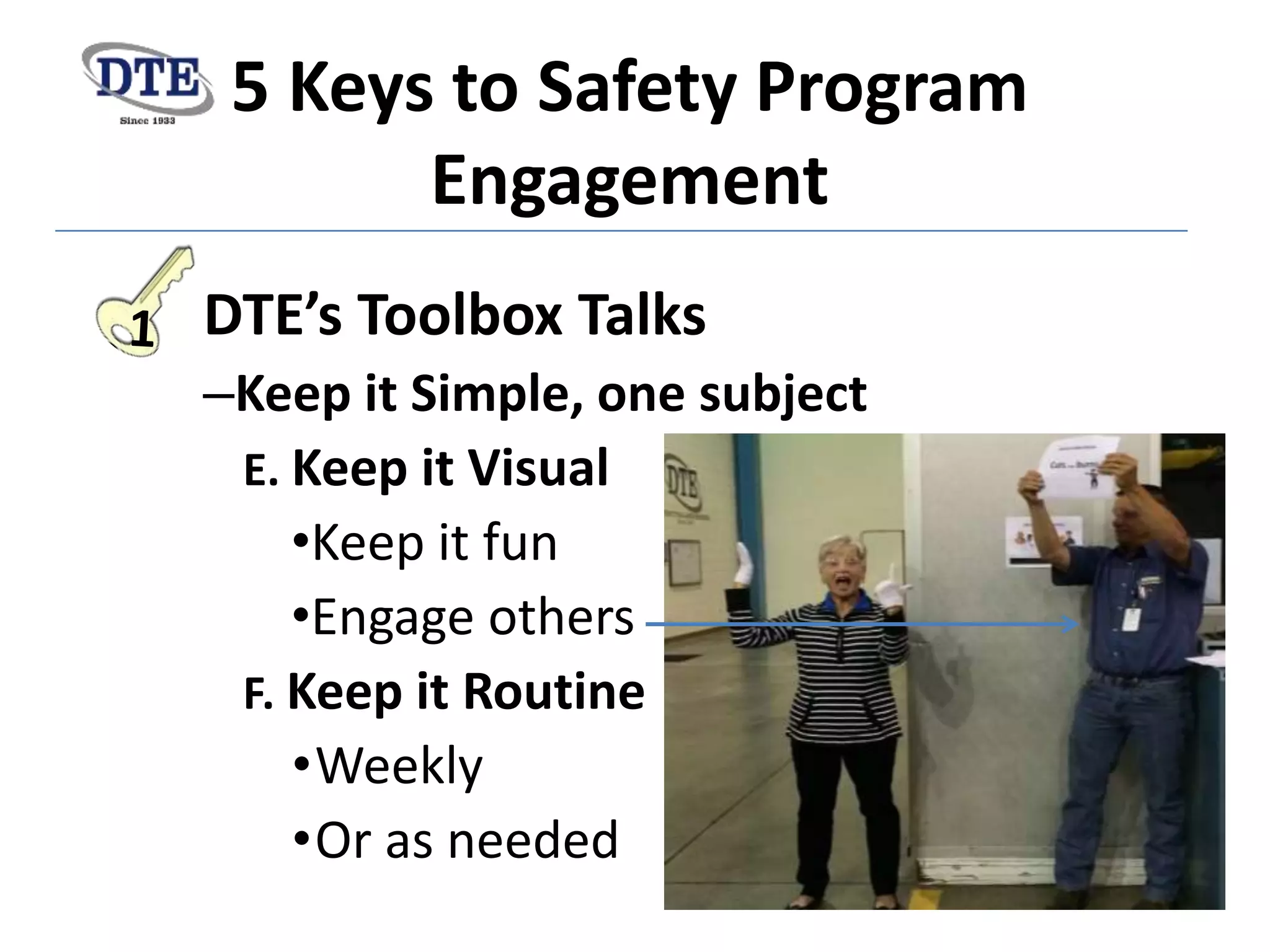

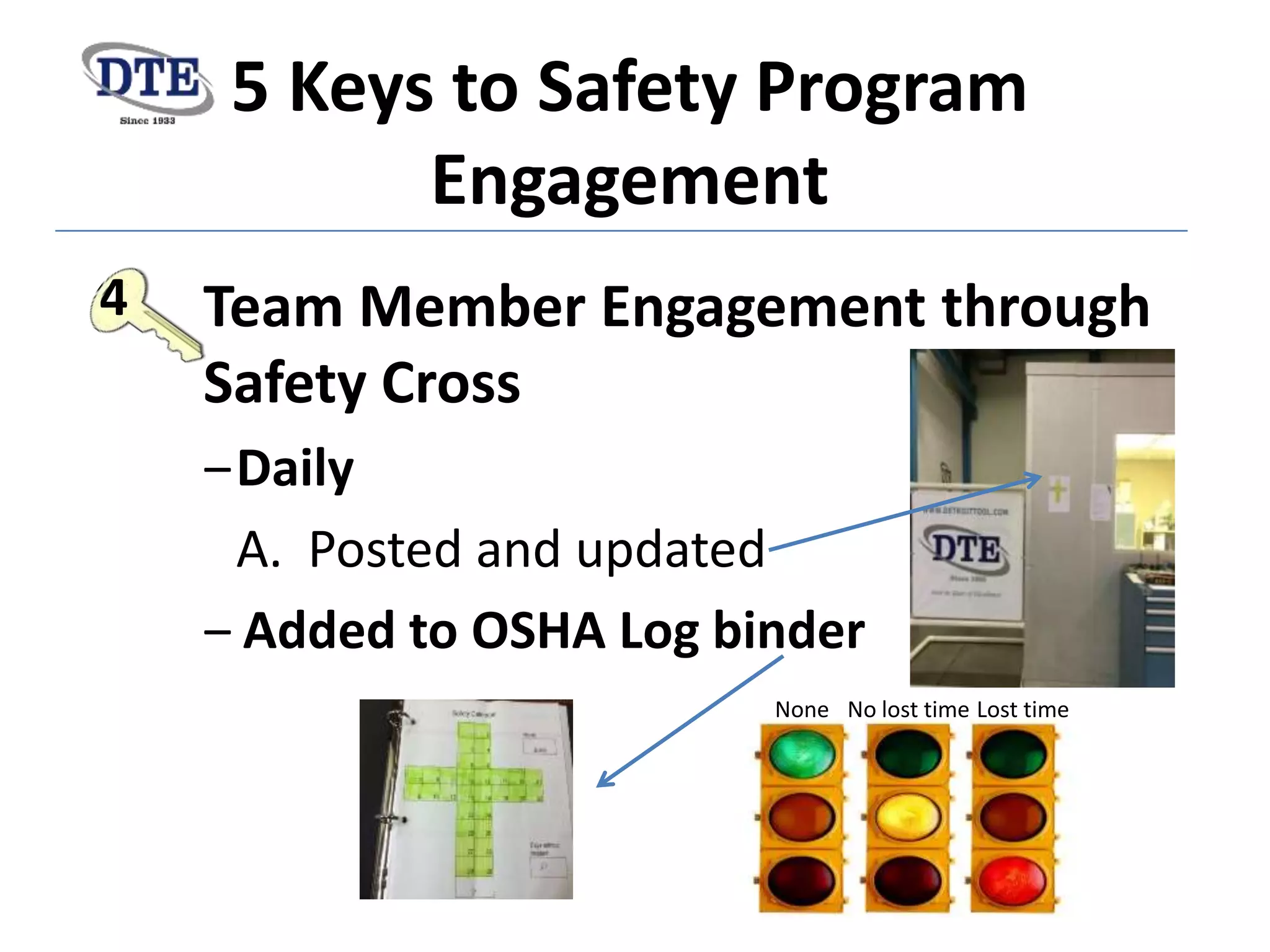

The document outlines five keys to enhance employee engagement in safety programs, emphasizing the importance of regular communication and positive reinforcement. It includes strategies like toolbox talks, safety committee meetings, and visuals to foster a safety-conscious culture. Key takeaways include the need for employee feedback and participation to create an effective safety environment.