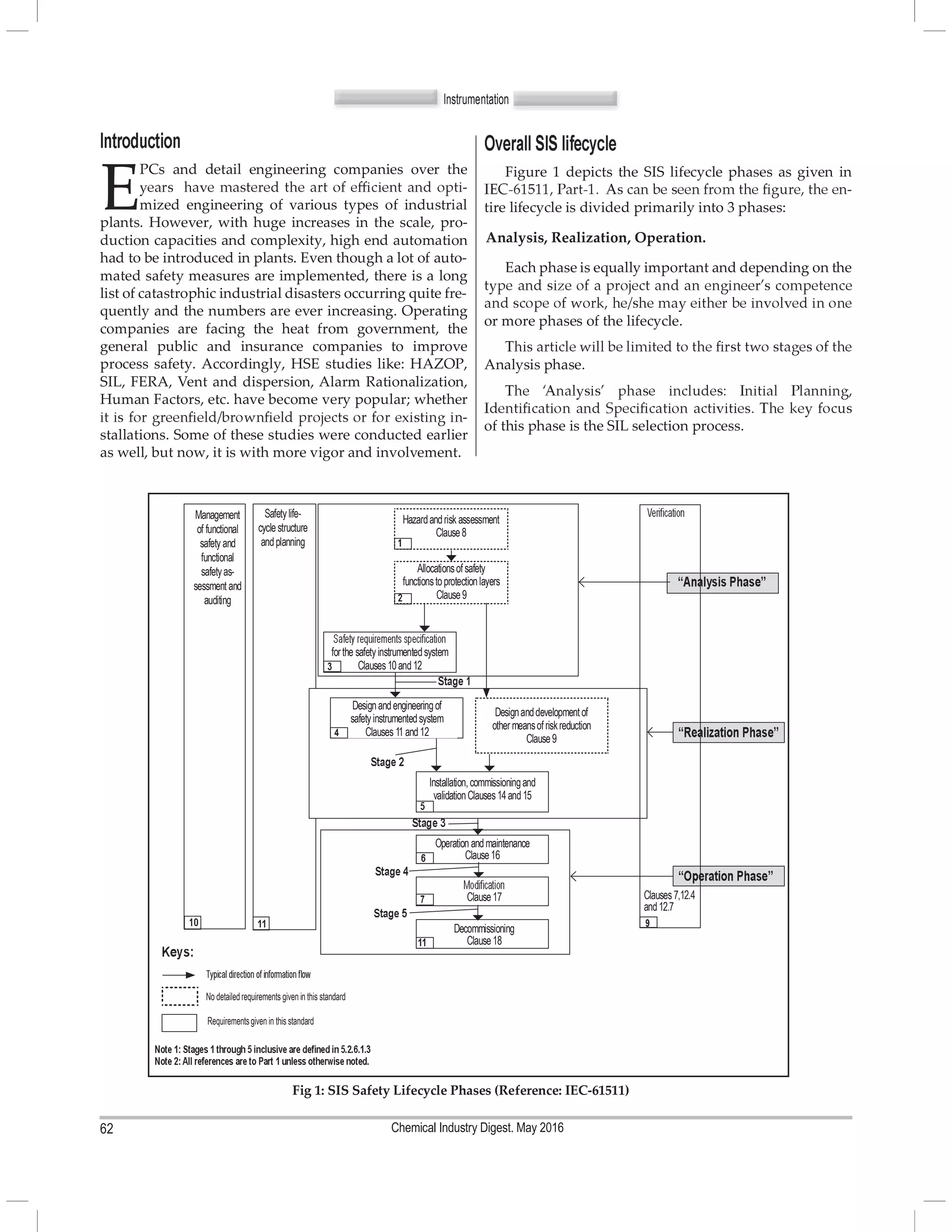

The document discusses safety instrumented systems (SIS) in engineering, procurement, and construction (EPC) project lifecycles. It describes the three phases of the SIS lifecycle: analysis, realization, and operation. The analysis phase begins with conceptual process design and ends with hazard and risk assessment and SIL selection. Key steps in the analysis phase include developing piping and instrumentation diagrams, conducting a HAZOP study to identify hazards, and performing a SIL selection study to determine the required safety integrity level for any safety instrumented functions. The analysis phase outputs documentation used as input for the realization phase of detailed design and installation. The document stresses the importance of properly planning and executing the analysis phase to avoid bypassing