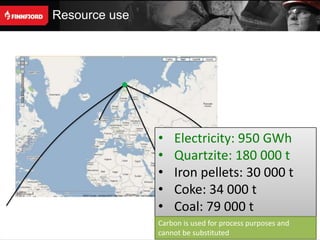

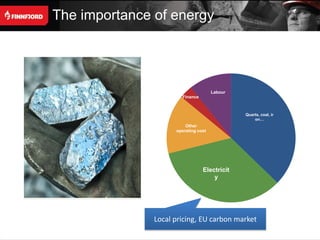

Finnfjord AS is a ferrosilicon manufacturing plant located in Finnsnes, Norway. It produces 100,000 tons of ferrosilicon and 15,000 tons of silica dust annually, using 950 GWh of electricity, 180,000 tons of quartzite, 30,000 tons of iron pellets, 34,000 tons of coke, and 79,000 tons of coal as resources. The plant employs 120 skilled workers. Finnfjord seeks to improve resource efficiency by recovering waste heat from furnaces to produce steam for industrial processes and district heating, as well as generating 340 GWh of electricity annually. This could reduce the plant's electricity consumption and associated CO2 emissions by up to