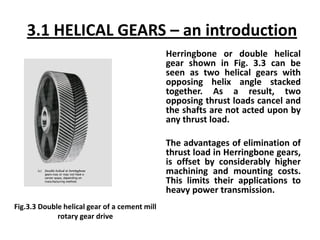

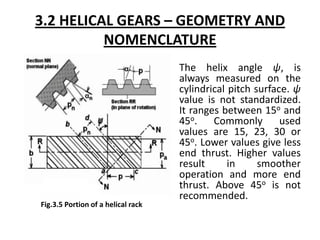

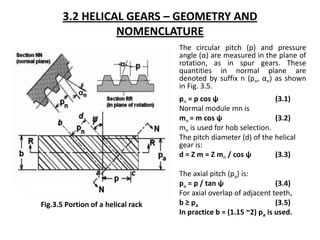

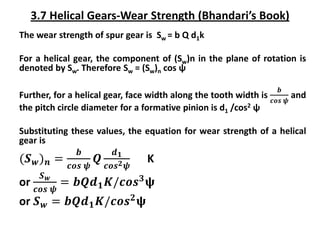

Helical gears transmit power between parallel shafts with teeth inclined to the axis, providing smoother operation than spur gears. Herringbone gears eliminate thrust load but have higher costs. Helical tooth shape is an involute helicoid. Geometry is defined including helix angle, circular/normal pitch, pressure angle, pitch diameter. Force analysis shows resultant load perpendicular to tooth. Bending stress is calculated in the normal plane using an equivalent number of teeth. Dynamic load and wear strength formulas account for helix angle effects. Buckinghams formulas give incremental dynamic load and design load. Wear strength depends on face width, pitch diameter, material properties and helix angle.

![3.7 Helical Gears-Wear Strength (Bhandari’s Book) Contd.

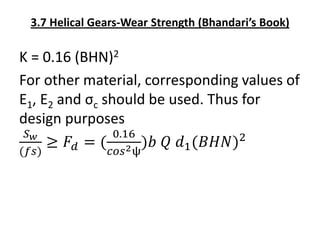

The pressure angle αn = 20o is in a plane normal to the tooth

element. Thus the K factor is given by

𝐾 =

1

1.4

[𝜎𝐶2 sin 𝛼𝑛 cos 𝛼𝑛

1

𝐸1

+

1

𝐸2

]

σc = Surface endurance strength (N/mm2)

E1, E2 = modulii of elasticity of materials for pinion and gear,

respectively, (N/mm2)

αn = pressure angle in a plane normal to the tooth element (20o)

For gears made of steel E1, E2 = 206000 N/mm2, and

αn = 20o

σc = 2.65 (BHN) N/mm2

Substituting these value

K = 0.16 (BHN)2](https://image.slidesharecdn.com/307027778-helical-gears-240125130727-a3bed3ec/85/307027778-Helical-Gears-pdf-17-320.jpg)