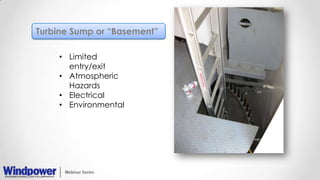

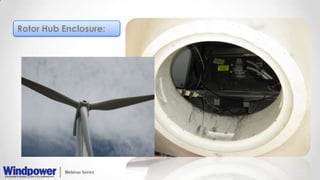

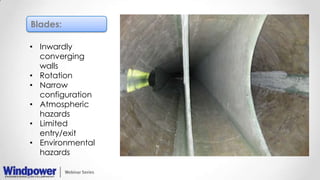

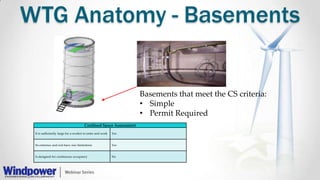

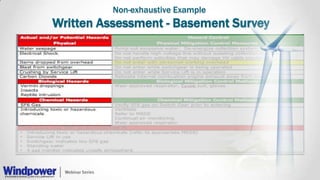

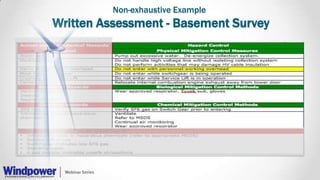

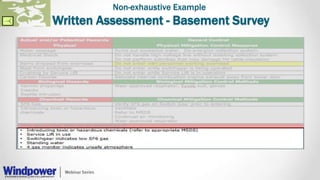

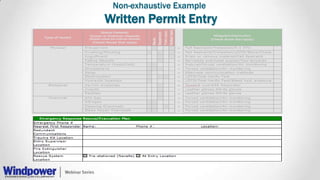

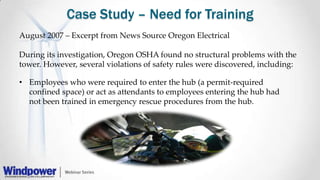

This webinar discusses compliance and safety regarding work in confined spaces for the windpower industry. It defines enclosed and permit-required confined spaces and outlines the hazards they present. Employers have duties to evaluate spaces, develop a written program, provide training, coordinate entry and ensure rescue procedures. The presentation examines common confined spaces in wind turbines like basements and hubs. It provides examples of hazard assessments, permits and safety requirements. Incidents demonstrate the need for proper training in rescue from confined spaces. Resources for more information are also shared.