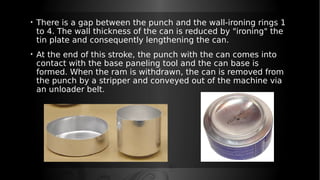

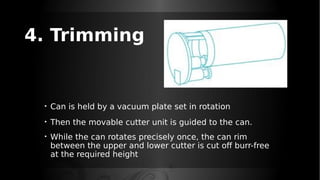

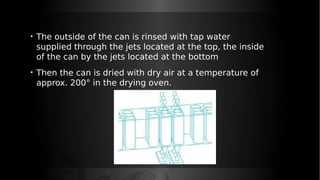

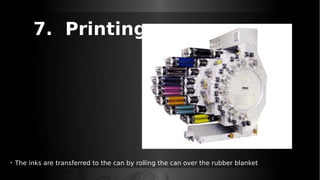

The document provides information about beverage cans and their manufacturing process. It discusses that beverage cans are aluminum containers that hold drinks like soda. The manufacturing process involves 14 main steps: 1) uncoiling aluminum sheet, 2) cupping, 3) wall-ironing and end forming, 4) trimming, 5) washing, 6) outside coating, 7) printing, 8) drying, 9) internal coating, 10) necking, 11) flanging, 12) end coating, 13) testing for defects, and 14) palletizing into stacks for transportation. Beverage cans are produced at high speeds through these automated steps to form the aluminum containers from coiled sheets.

![Thank you for

listening!! =]](https://image.slidesharecdn.com/259899745-beverage-can-manufacturing-process-230517235520-f76437b3/85/259899745-Beverage-Can-Manufacturing-Process-pdf-38-320.jpg)