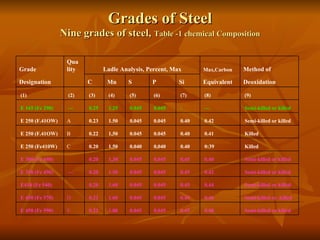

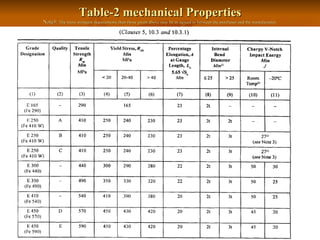

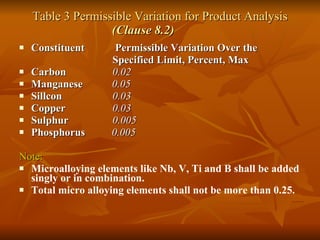

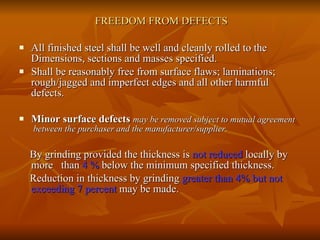

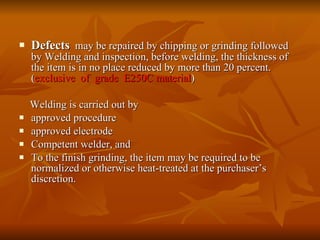

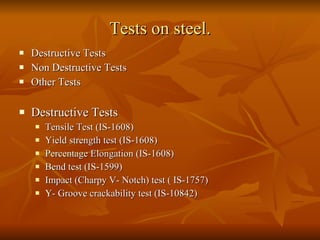

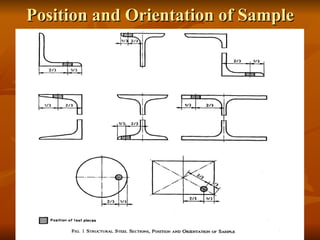

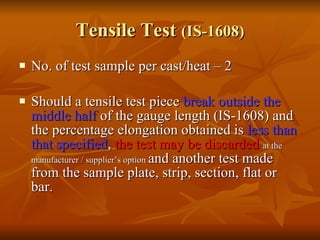

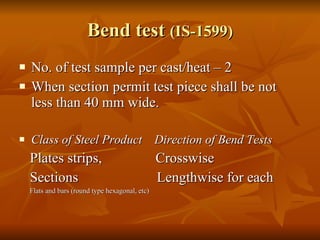

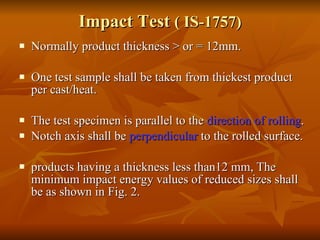

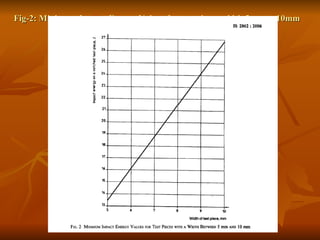

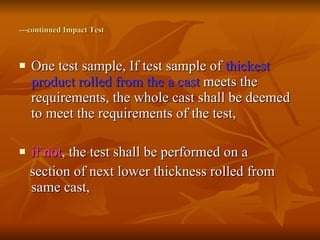

The document outlines the requirements for nine grades of hot rolled low, medium, and high tensile structural steel according to the Indian Standard 2062:2006. It specifies chemical composition limits and mechanical properties for each grade. It also describes testing requirements, including tensile testing, bend testing, and impact testing to ensure the steel meets specifications. Defect and freedom from defect standards are provided as well as permissible variations in chemical analysis and testing positions.