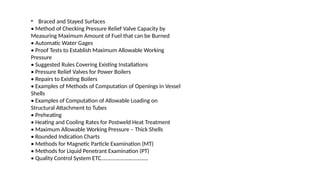

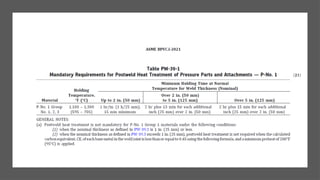

The document provides an introduction to ASME Section I, which outlines rules for the construction of power boilers, emphasizing safety and historical context. It details the section's organizational structure, scope, major parts regarding various types of boilers, and the construction process, including materials, design, welding, and inspection requirements. The document serves as a guide for understanding the standards and practices necessary for safe boiler design and operation.