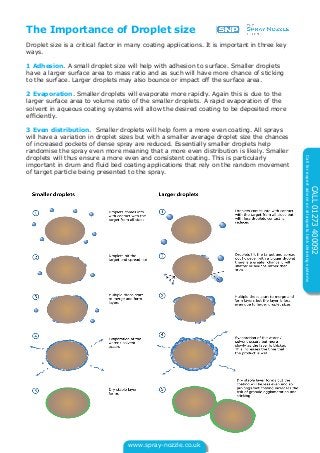

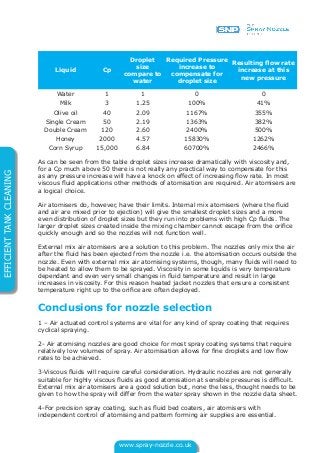

The document discusses various spray coating applications in food processing, categorizing them into aqueous, heated liquid, and bonded coatings, and details delivery methods such as continuous and drum coatings. It emphasizes the significance of droplet size on adhesion, evaporation, and even distribution, suggesting techniques to achieve consistent spray patterns and cope with variable runs and viscous fluids. Additionally, it highlights the importance of nozzle selection, particularly the use of air atomisers for precision applications where viscosity poses challenges.