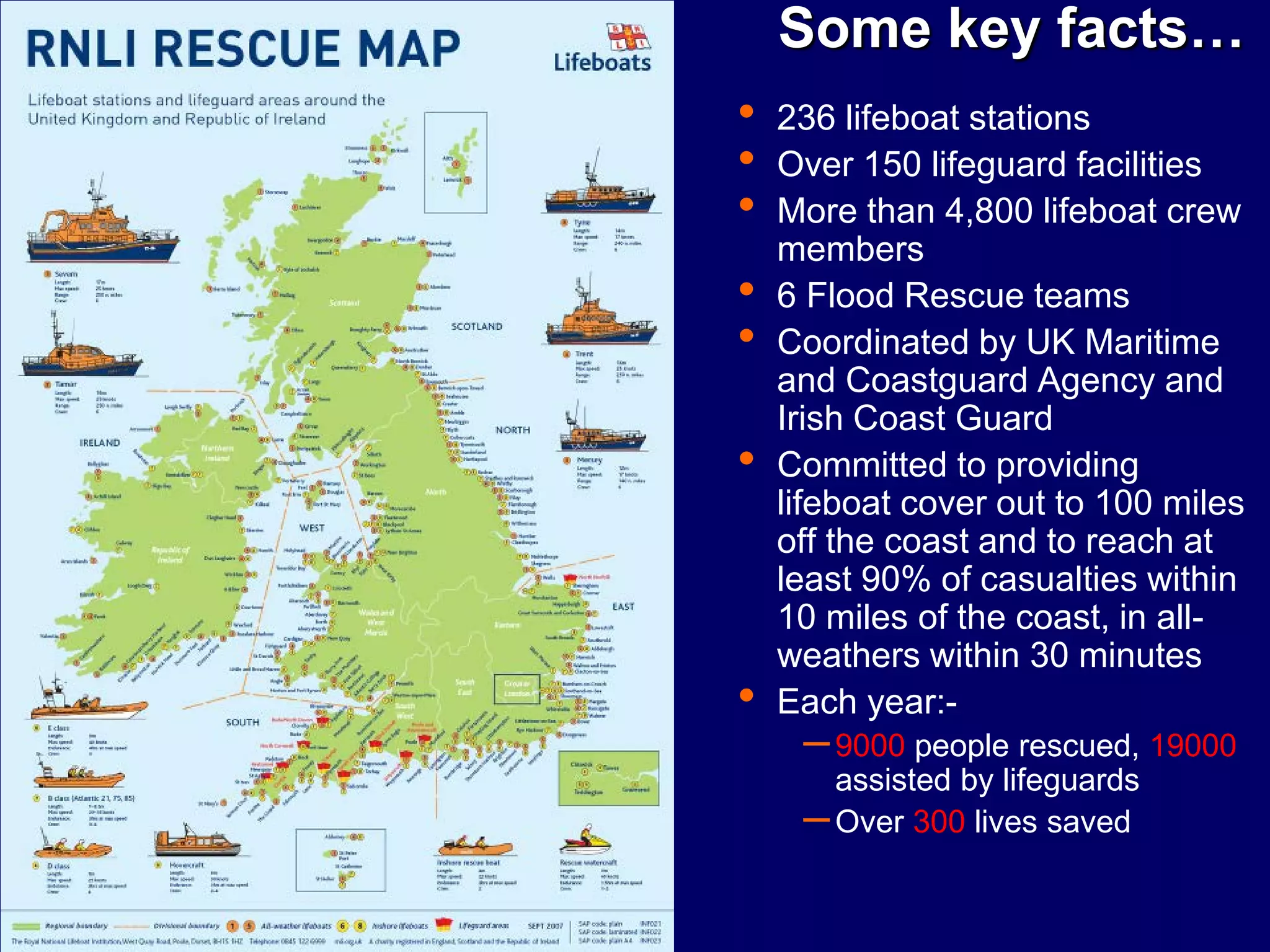

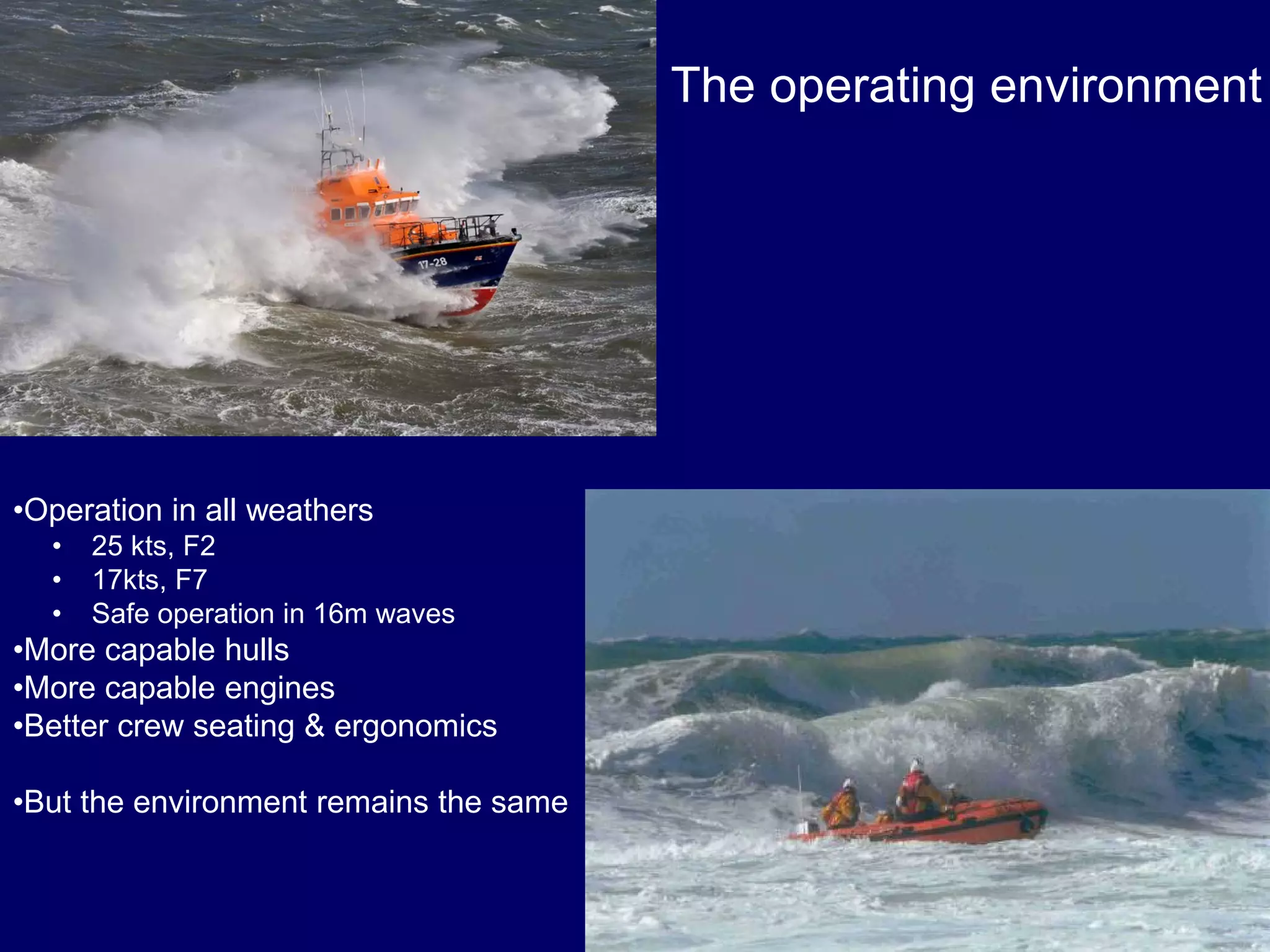

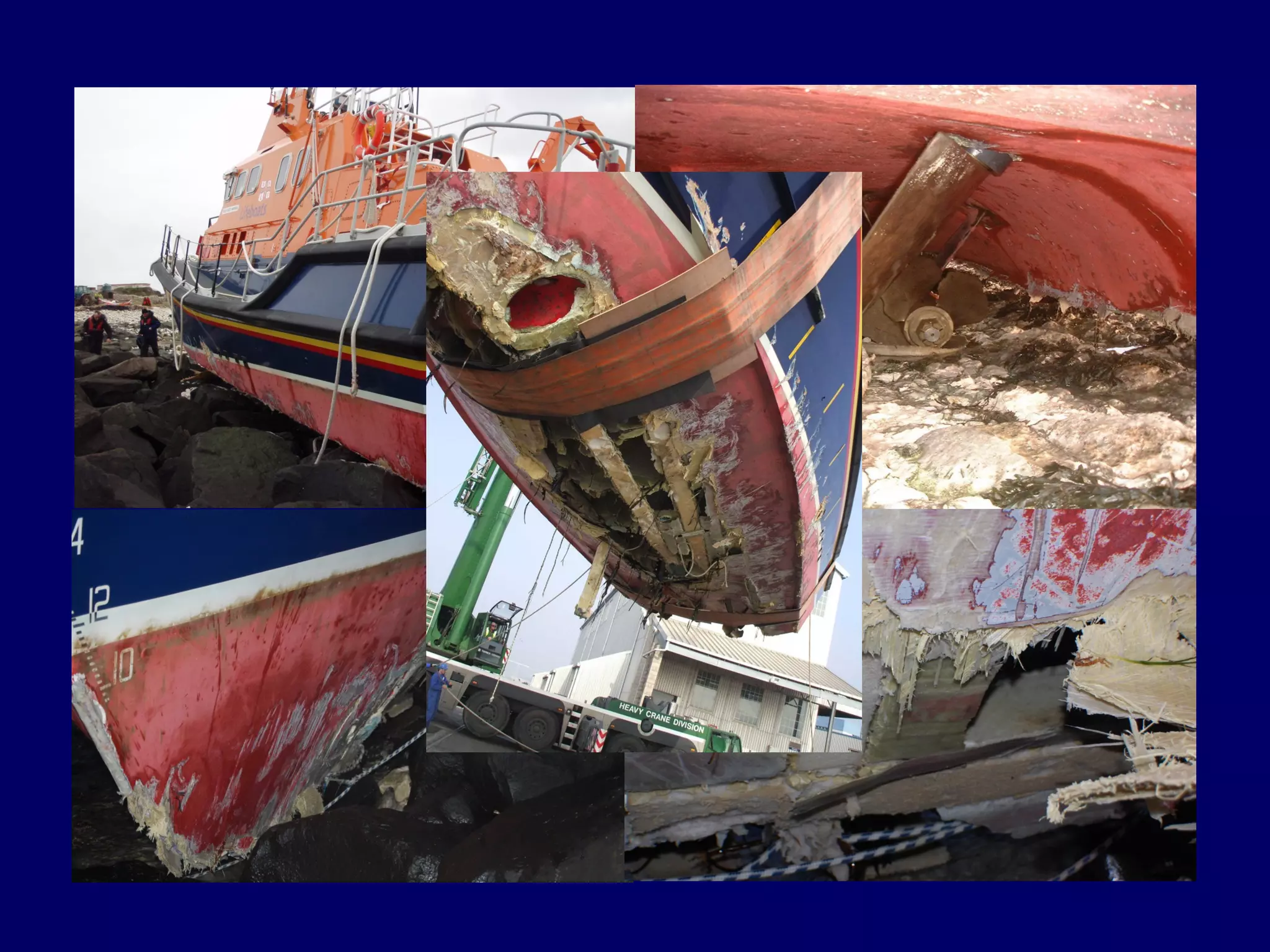

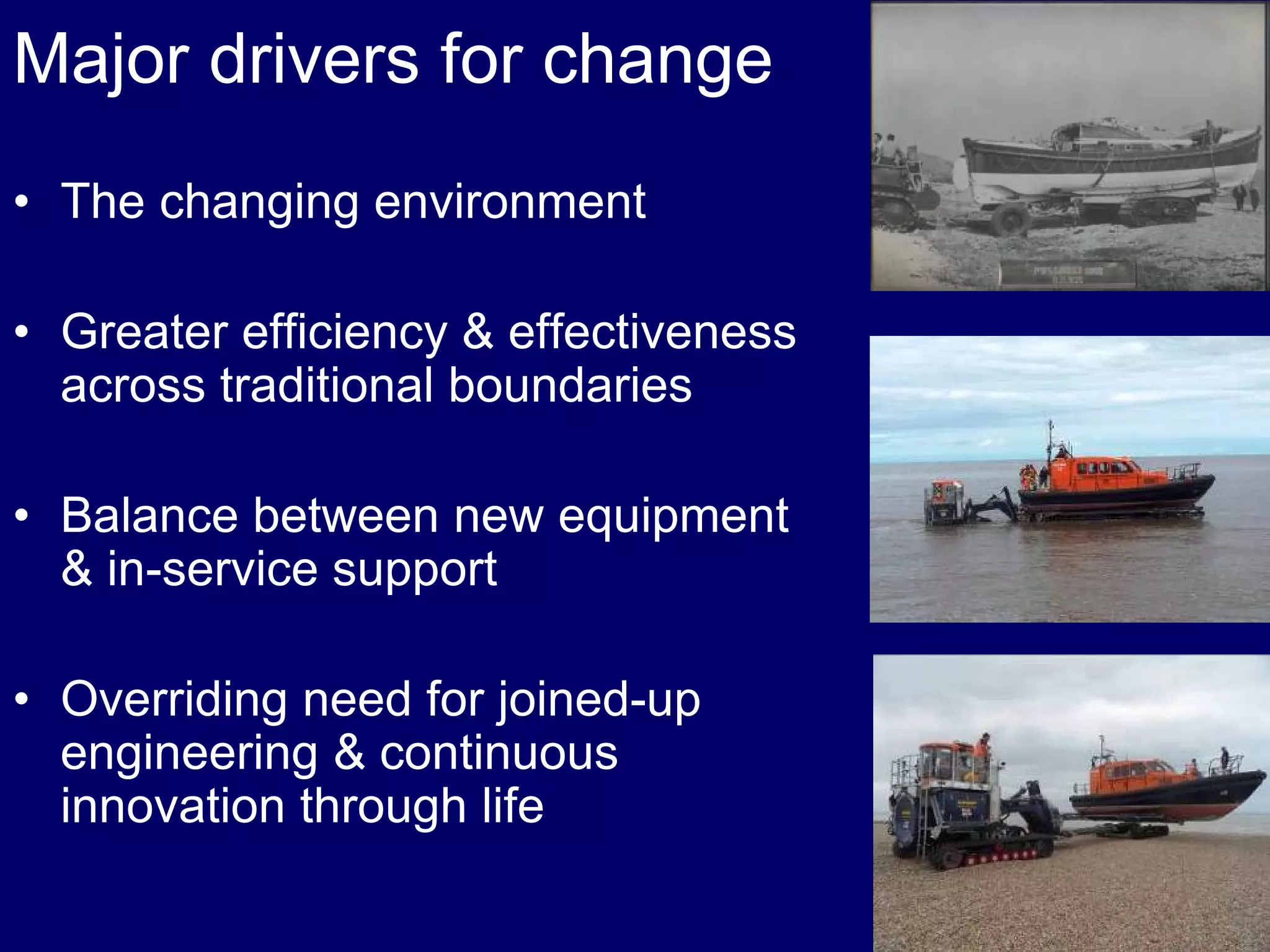

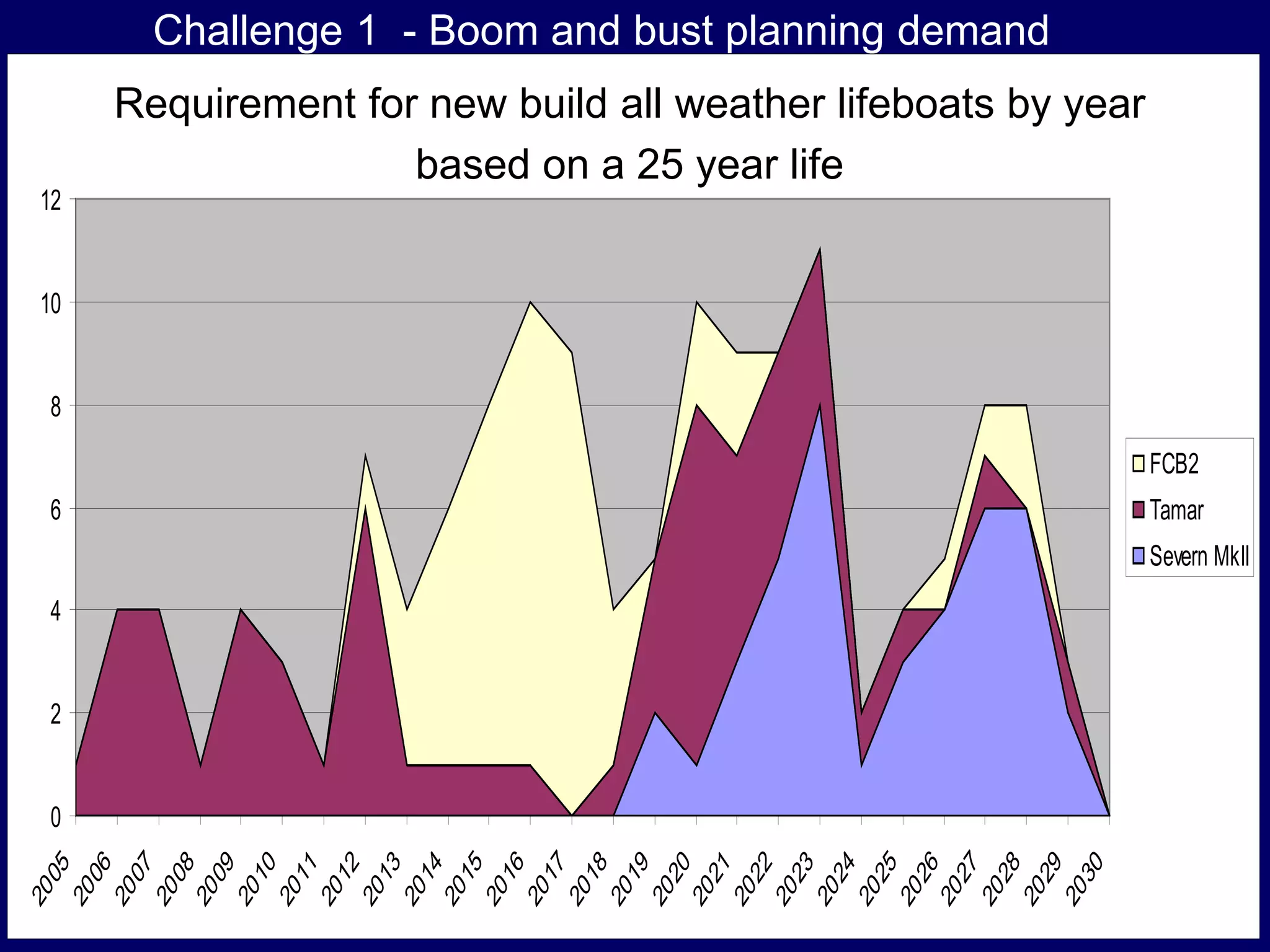

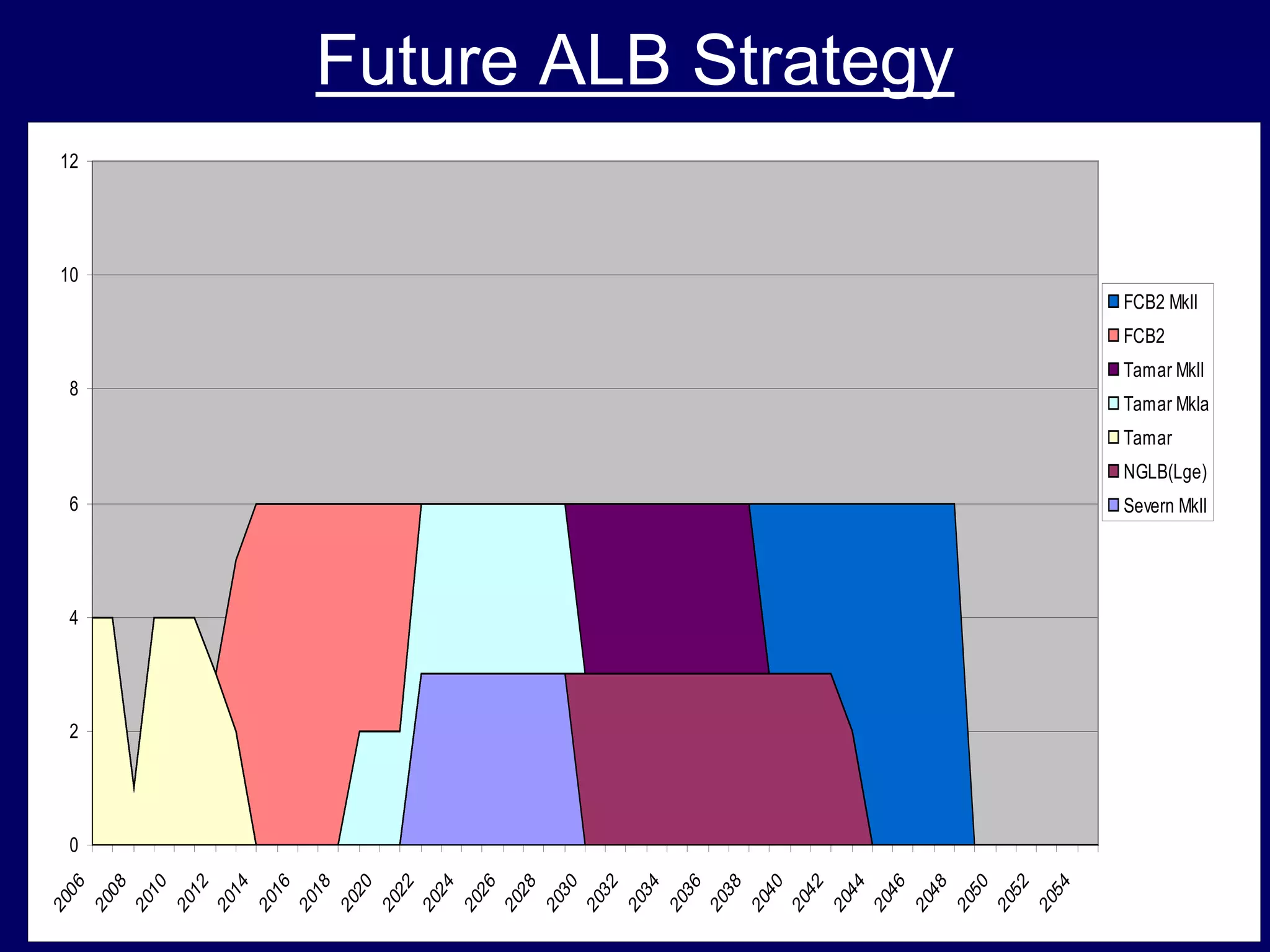

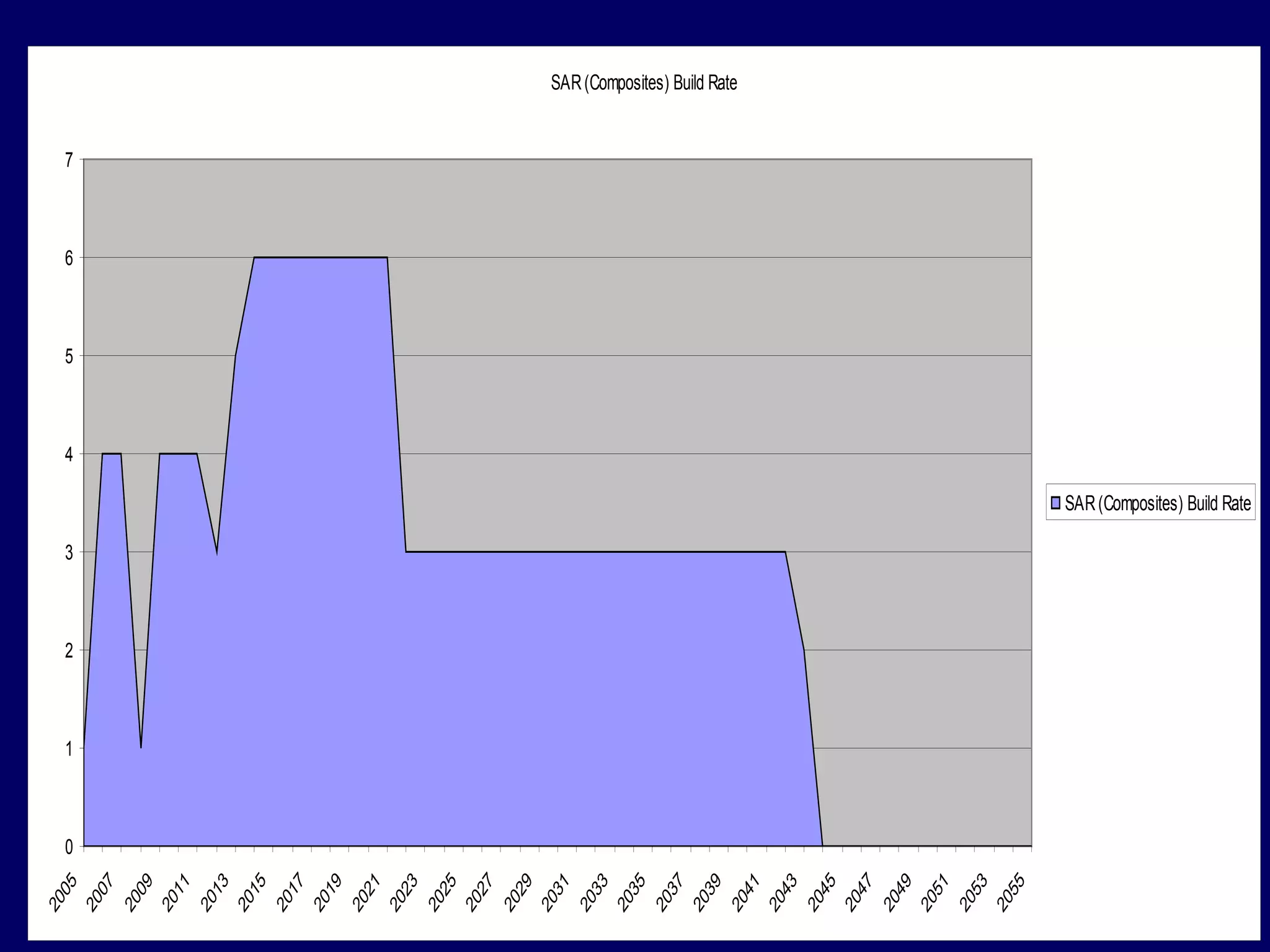

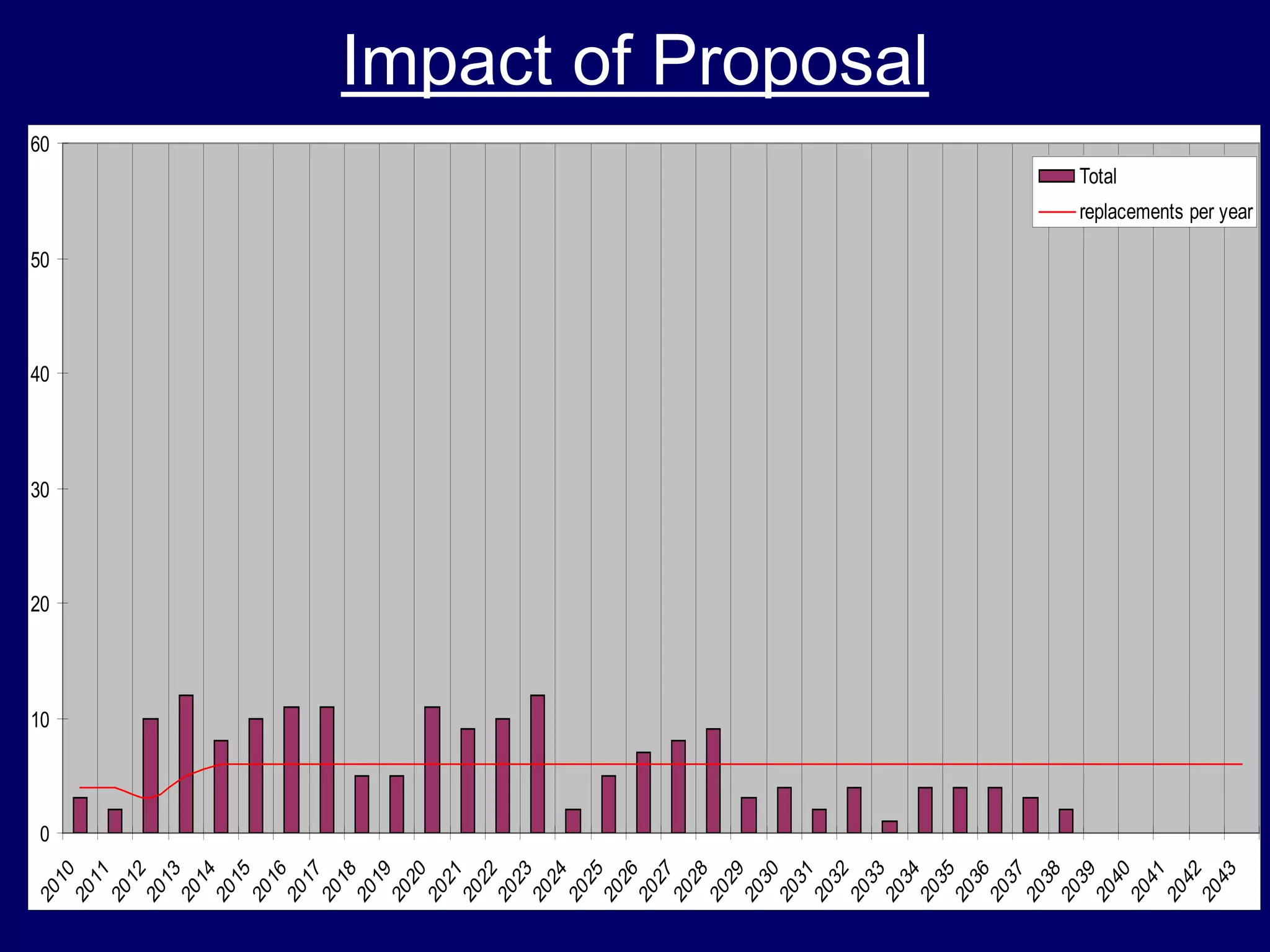

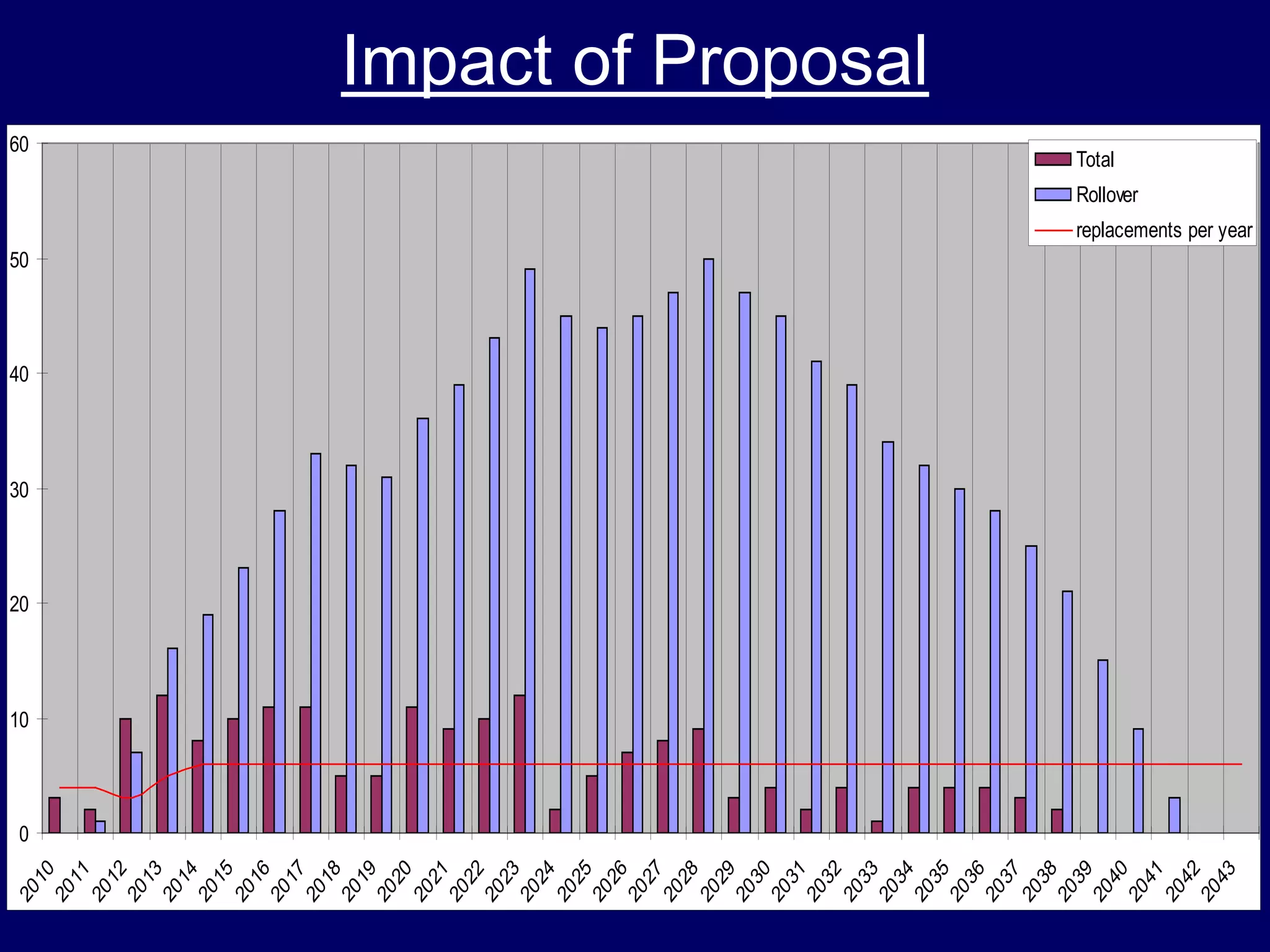

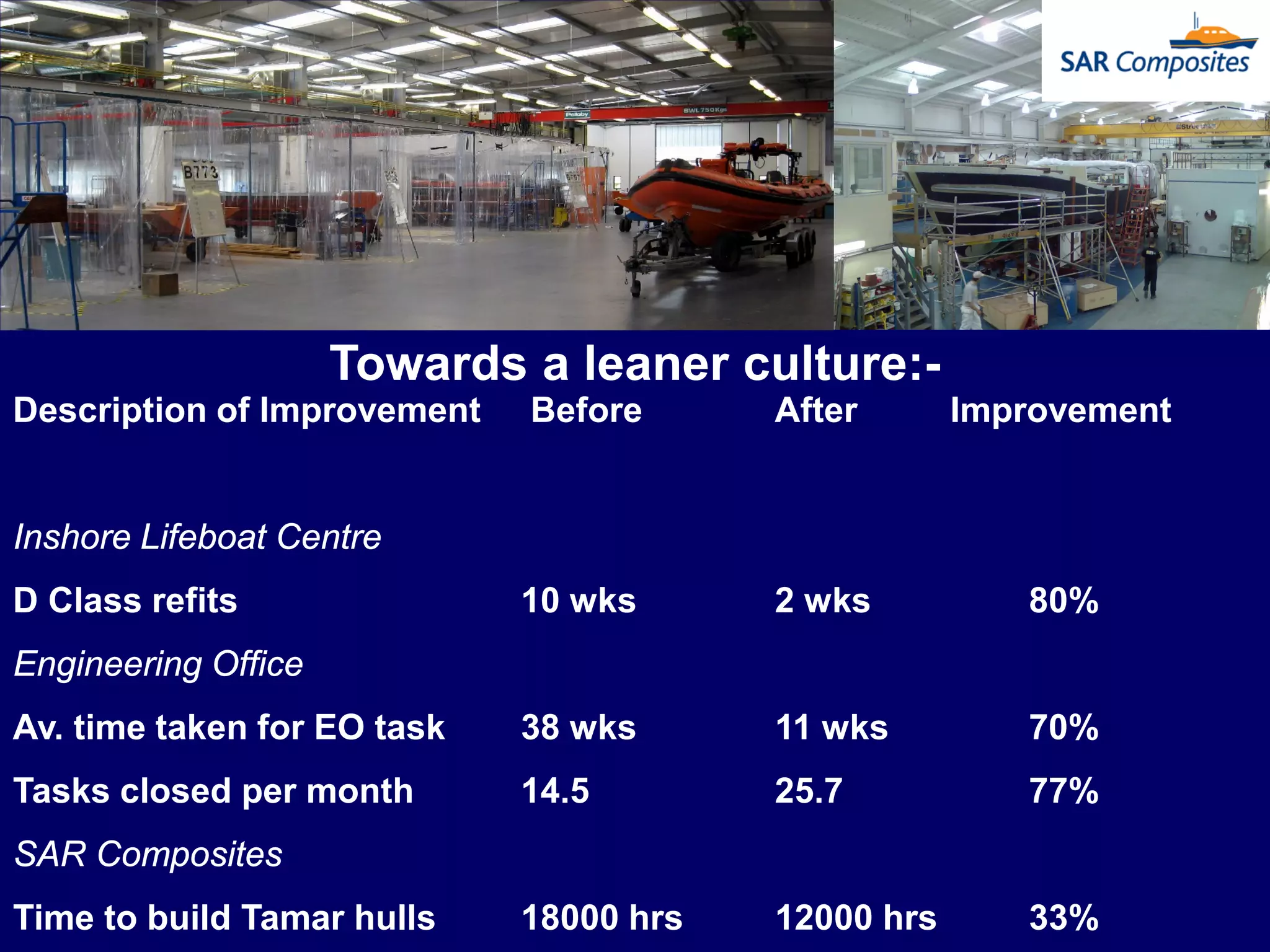

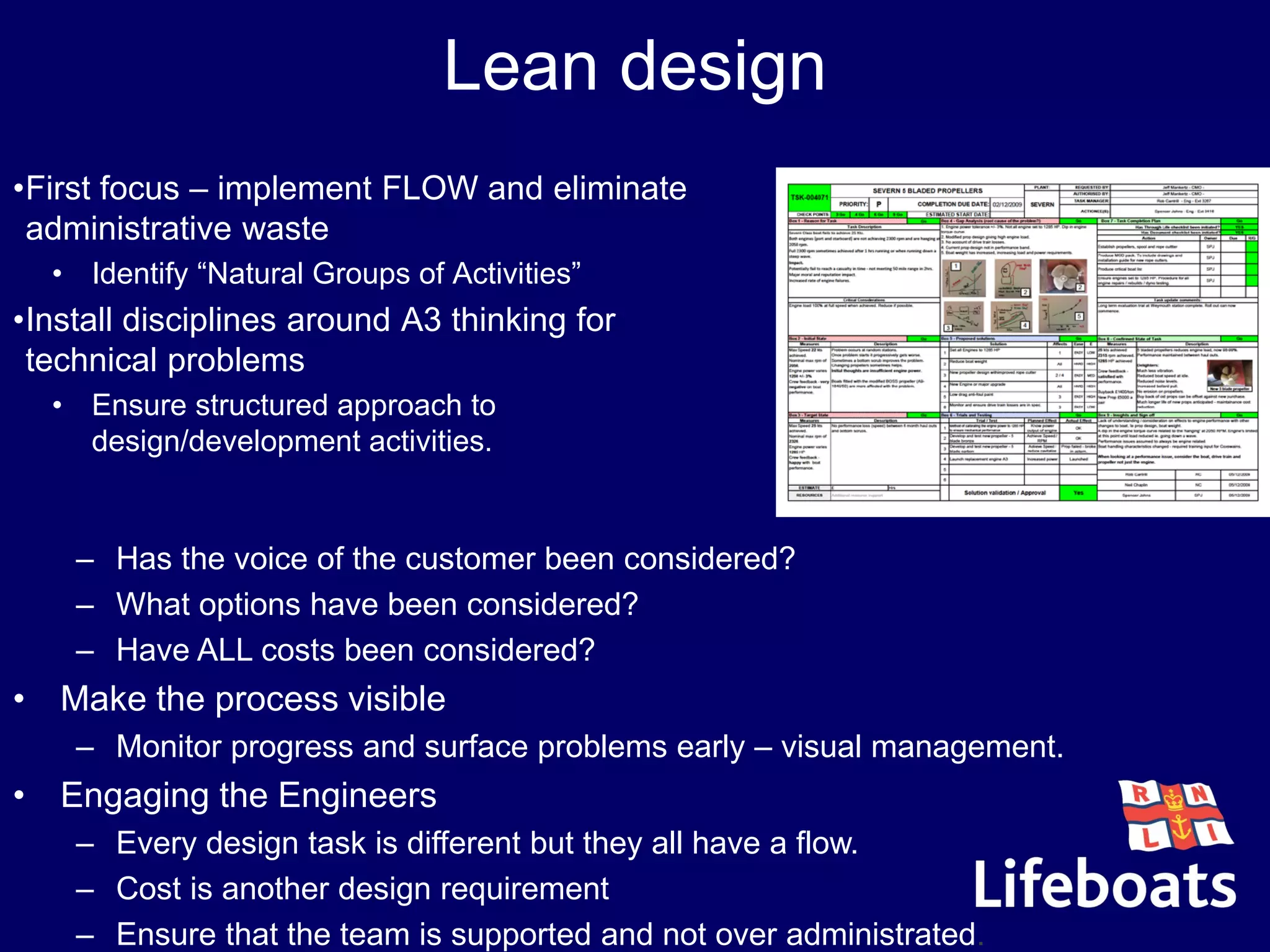

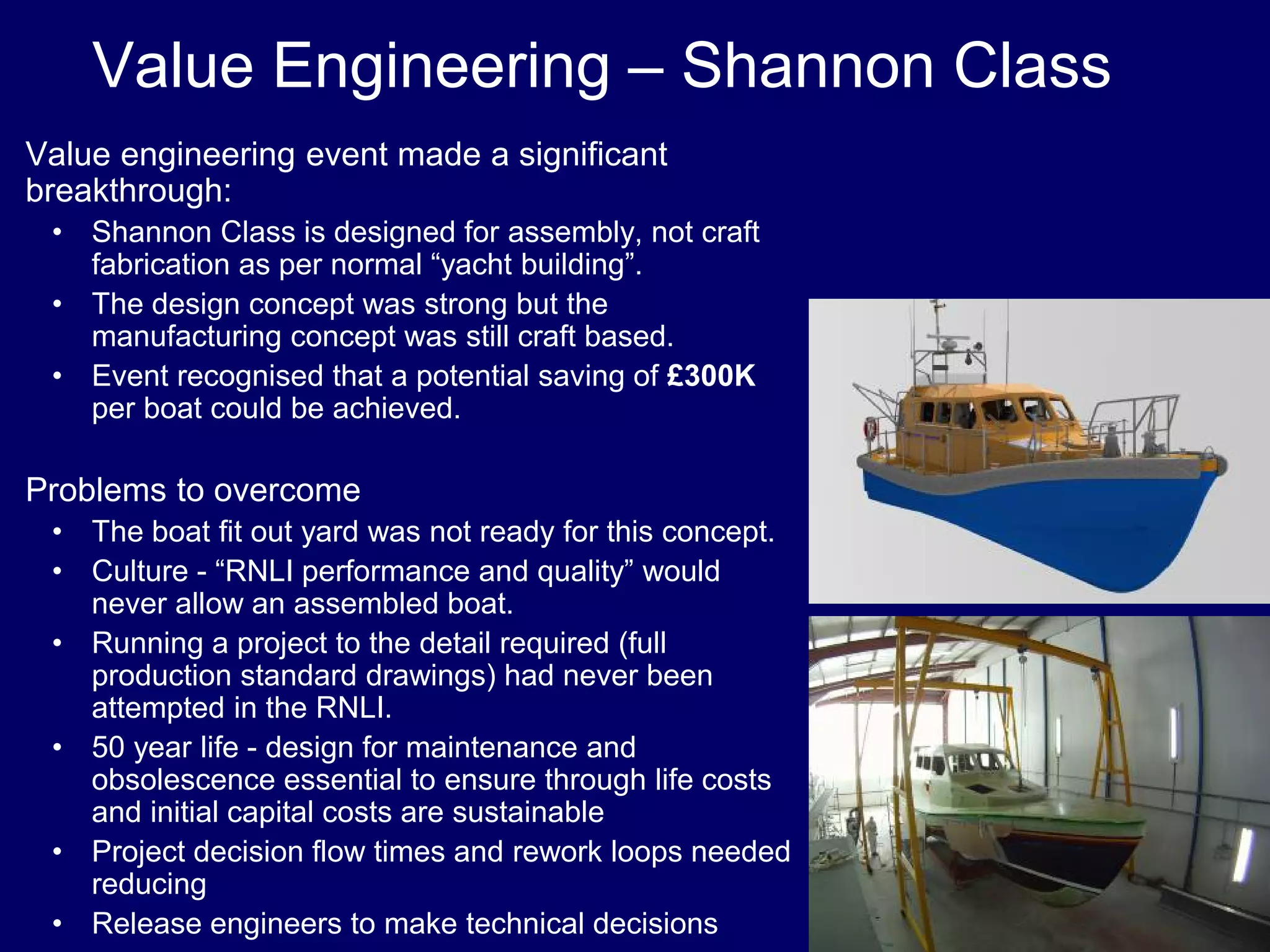

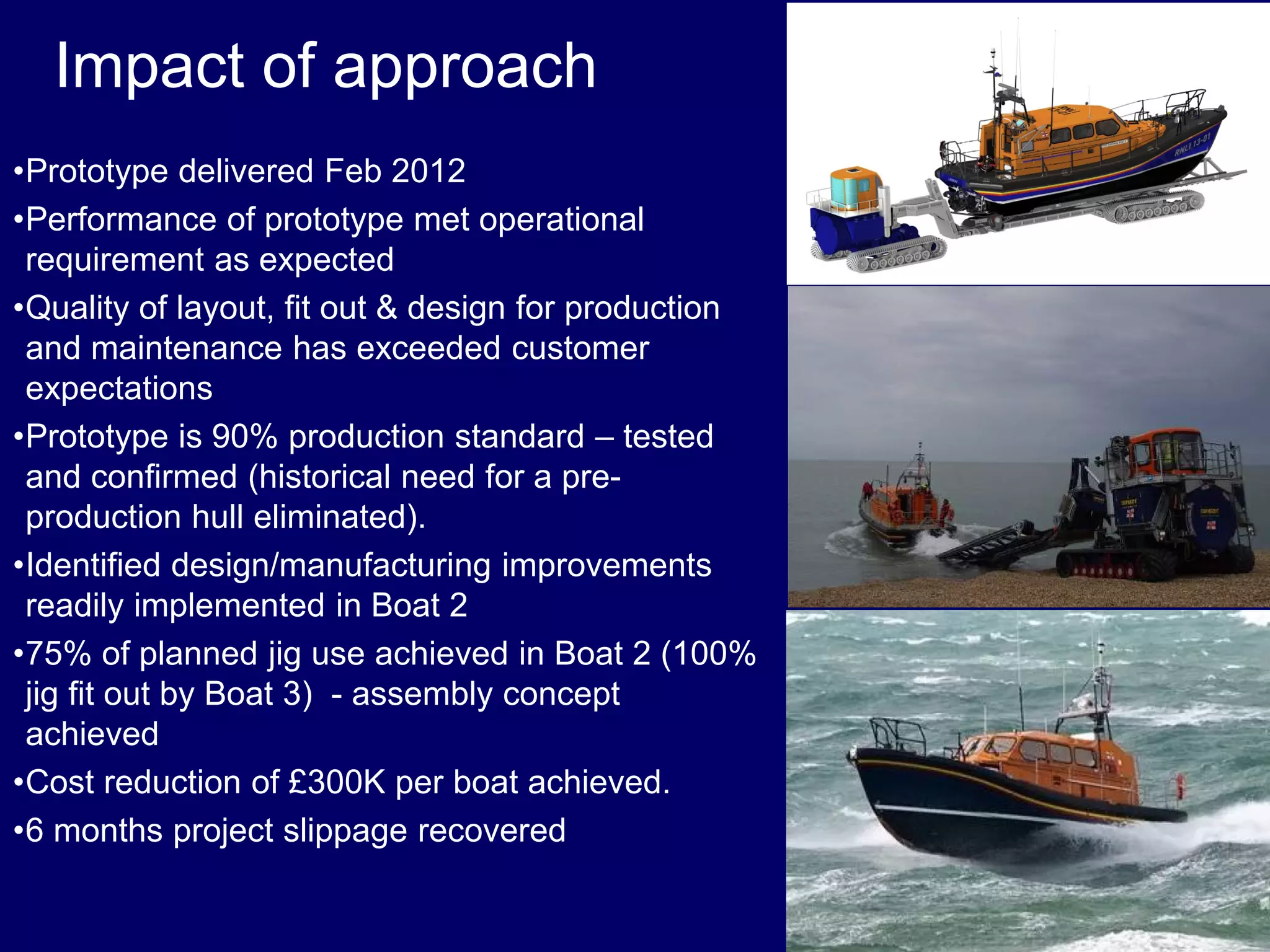

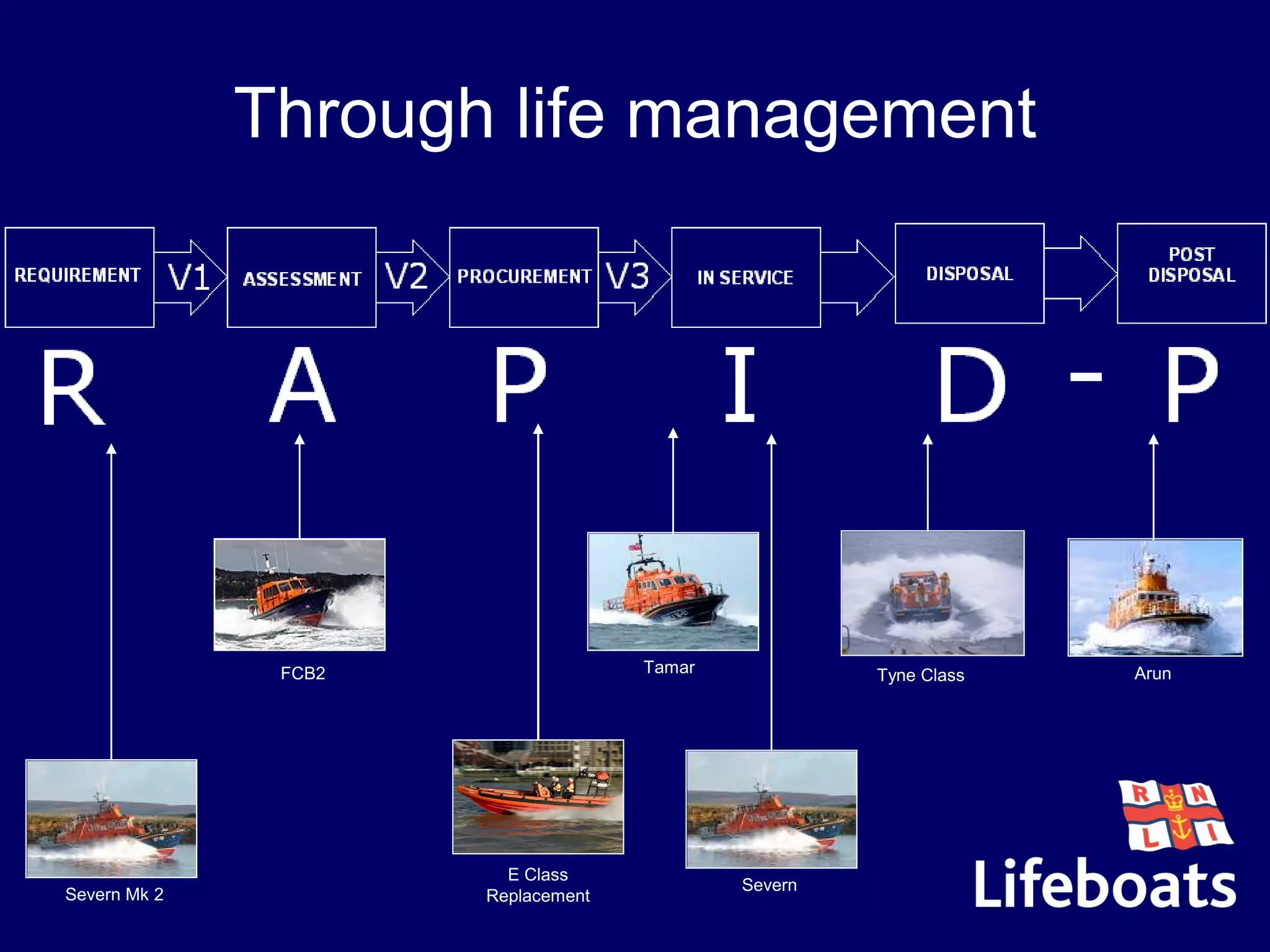

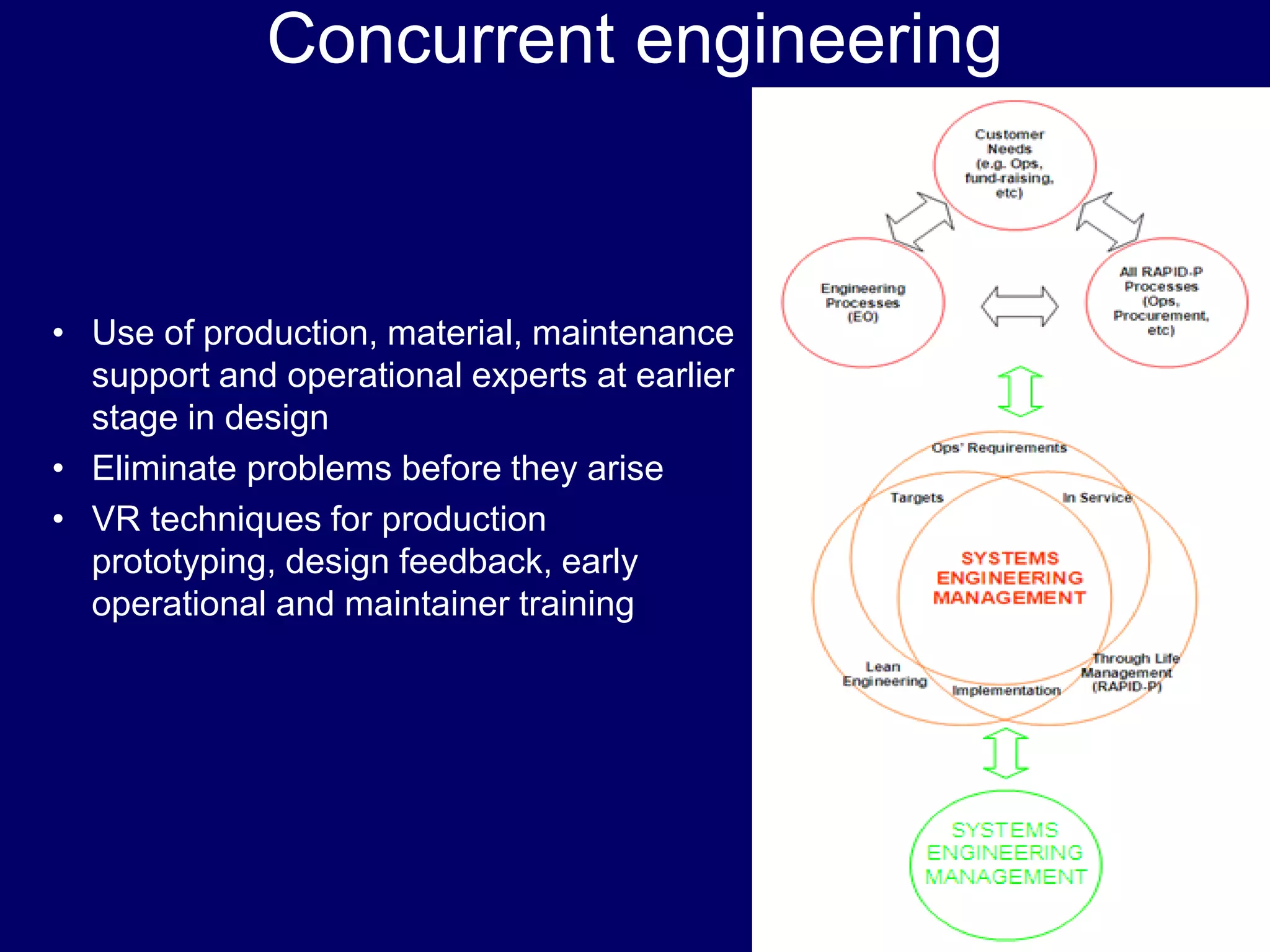

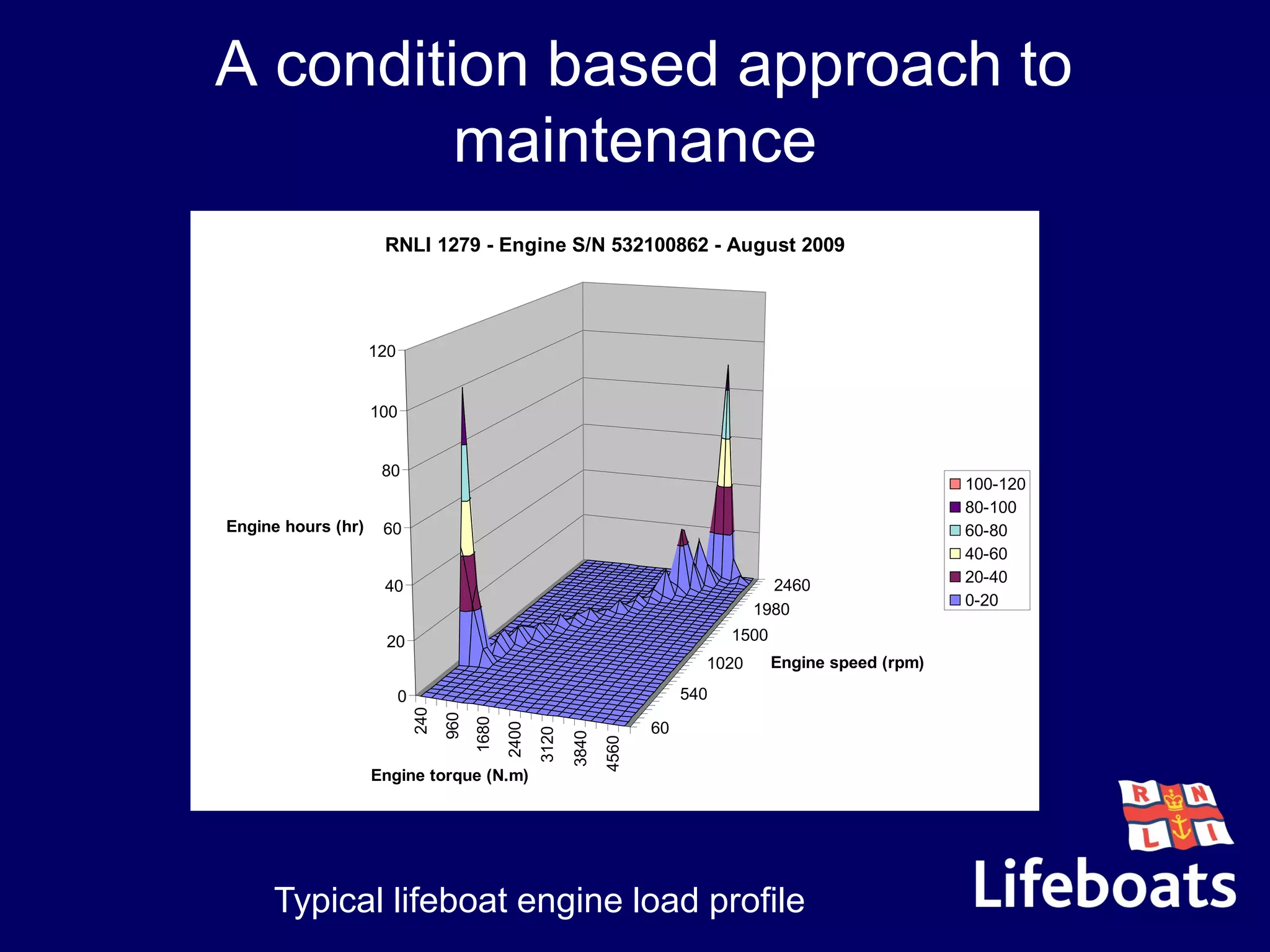

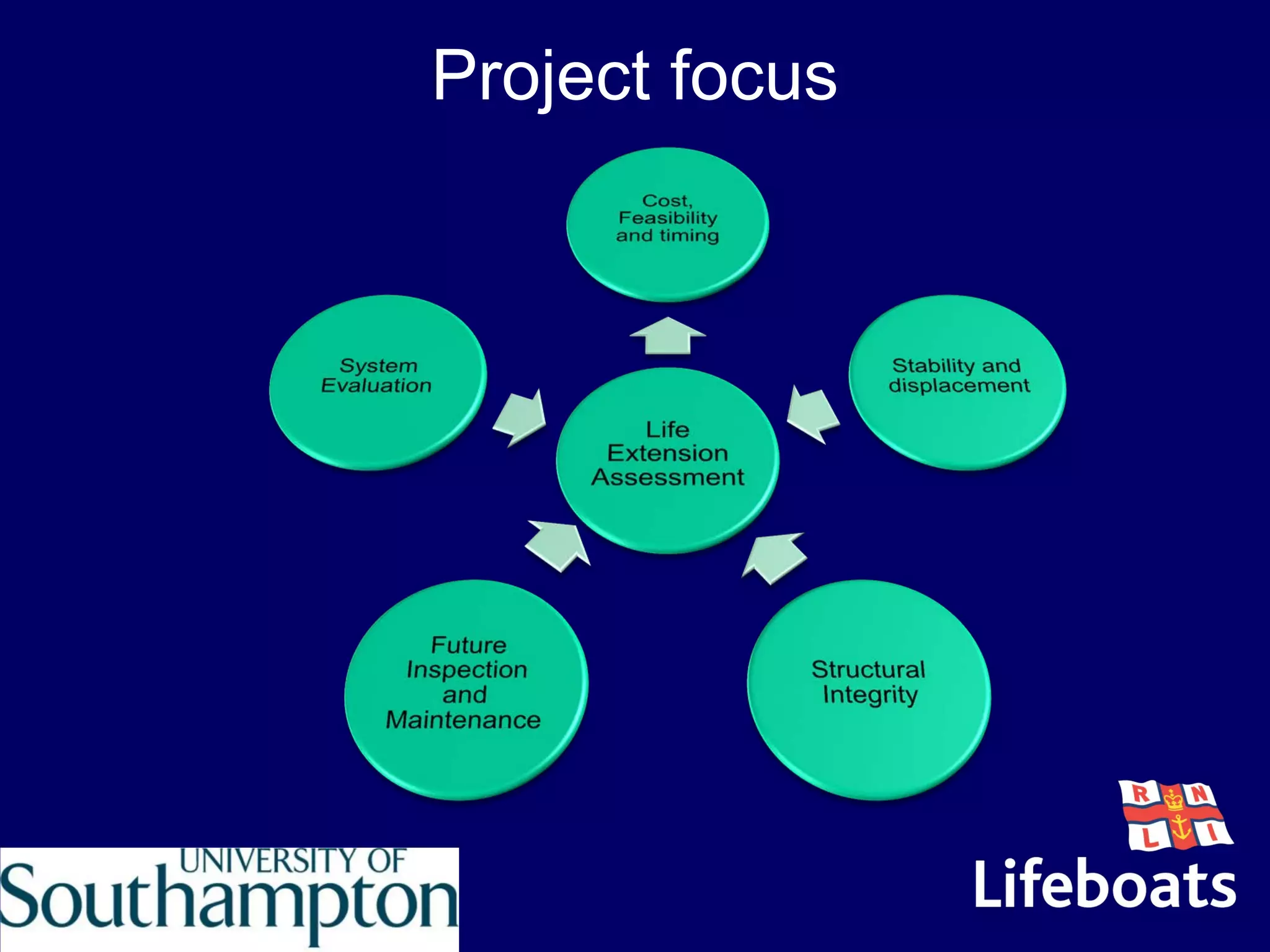

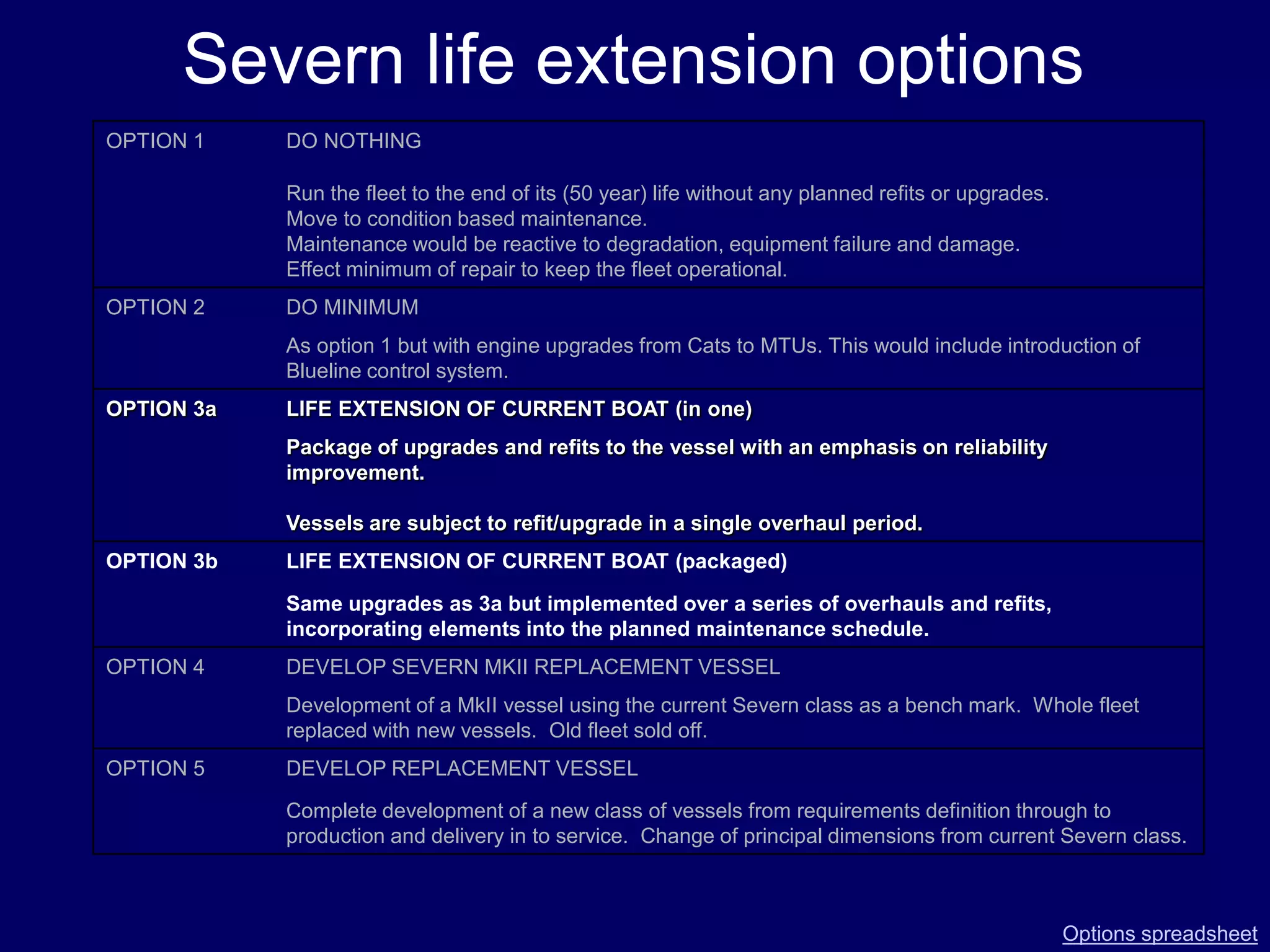

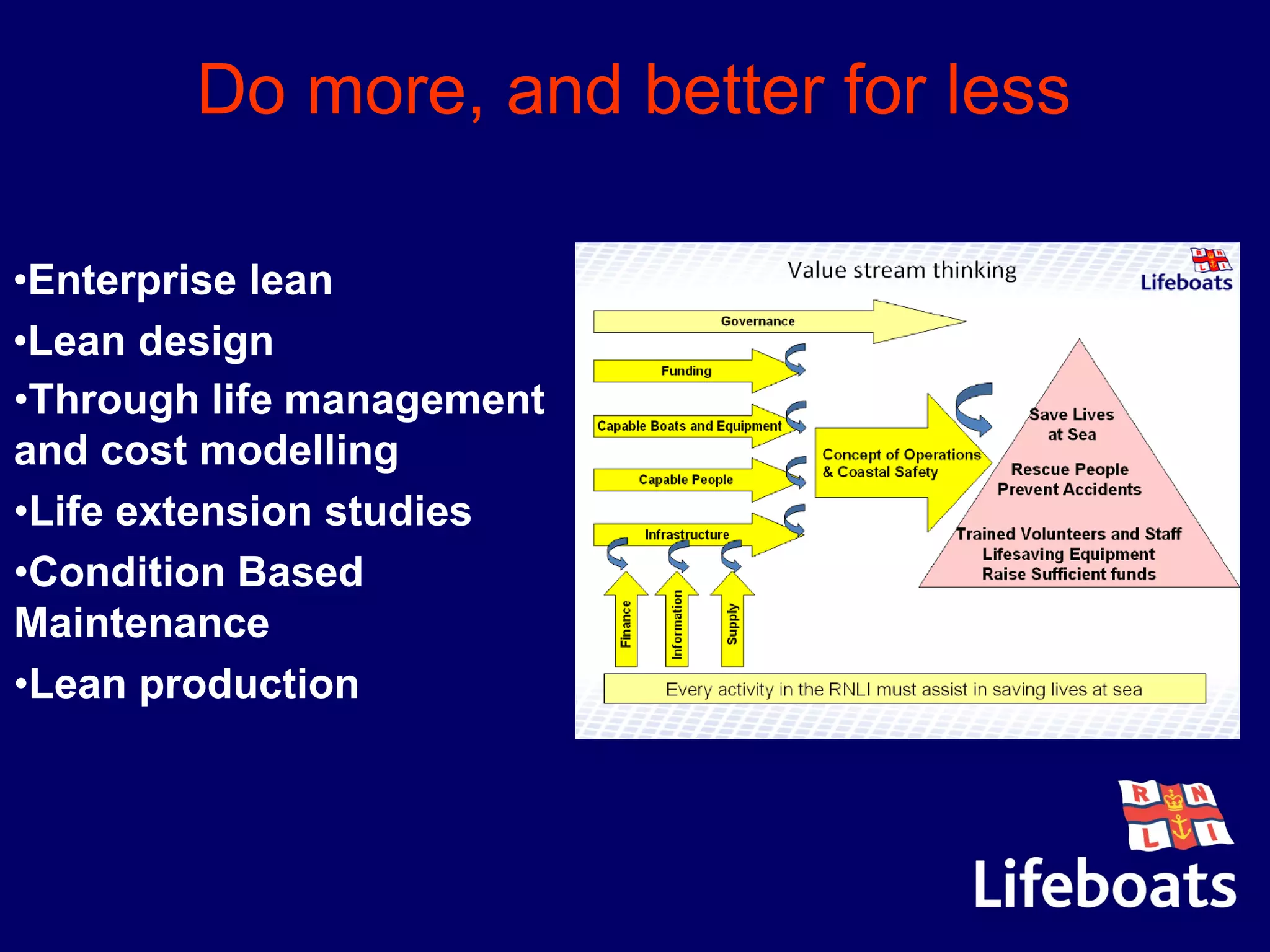

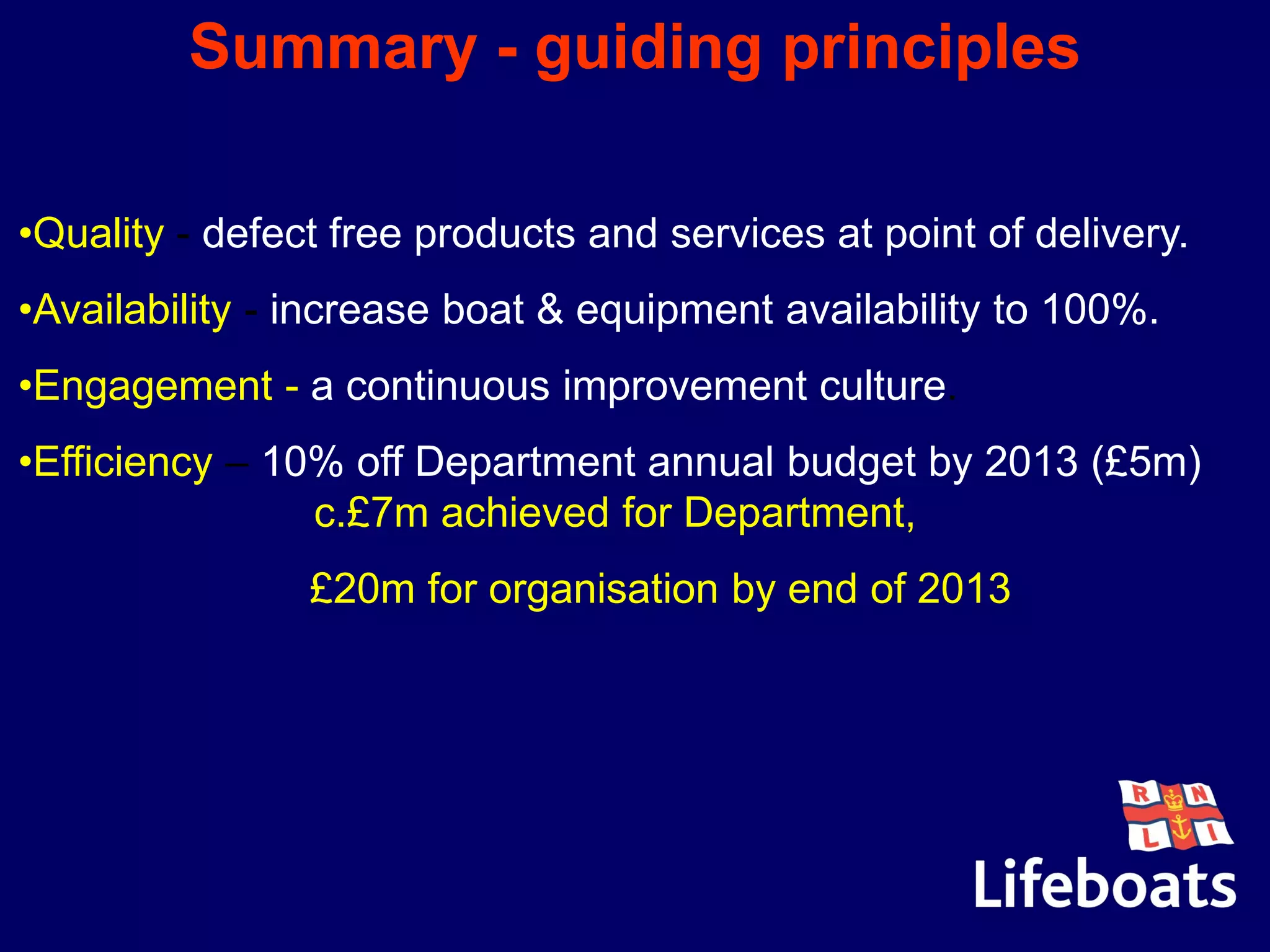

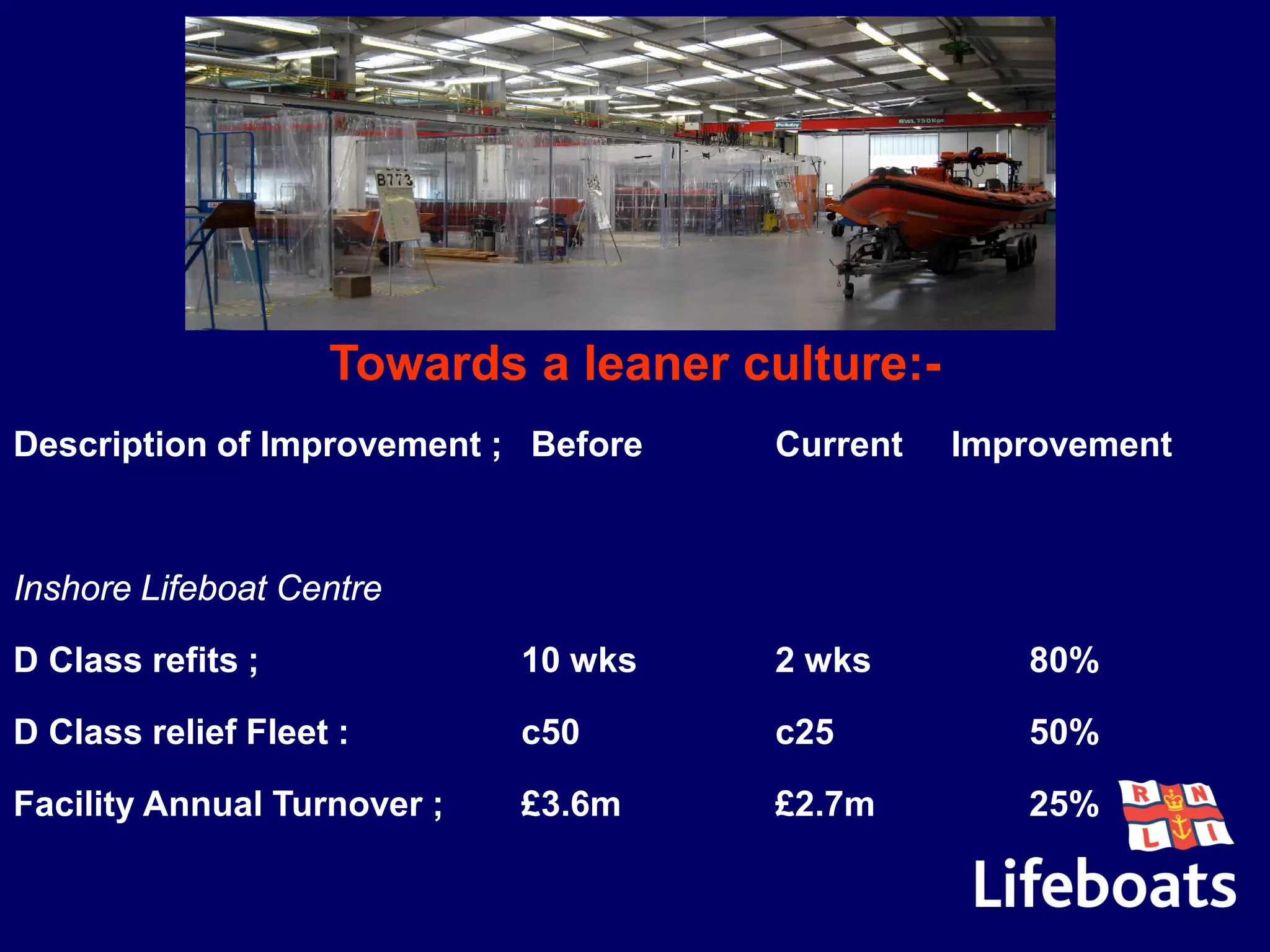

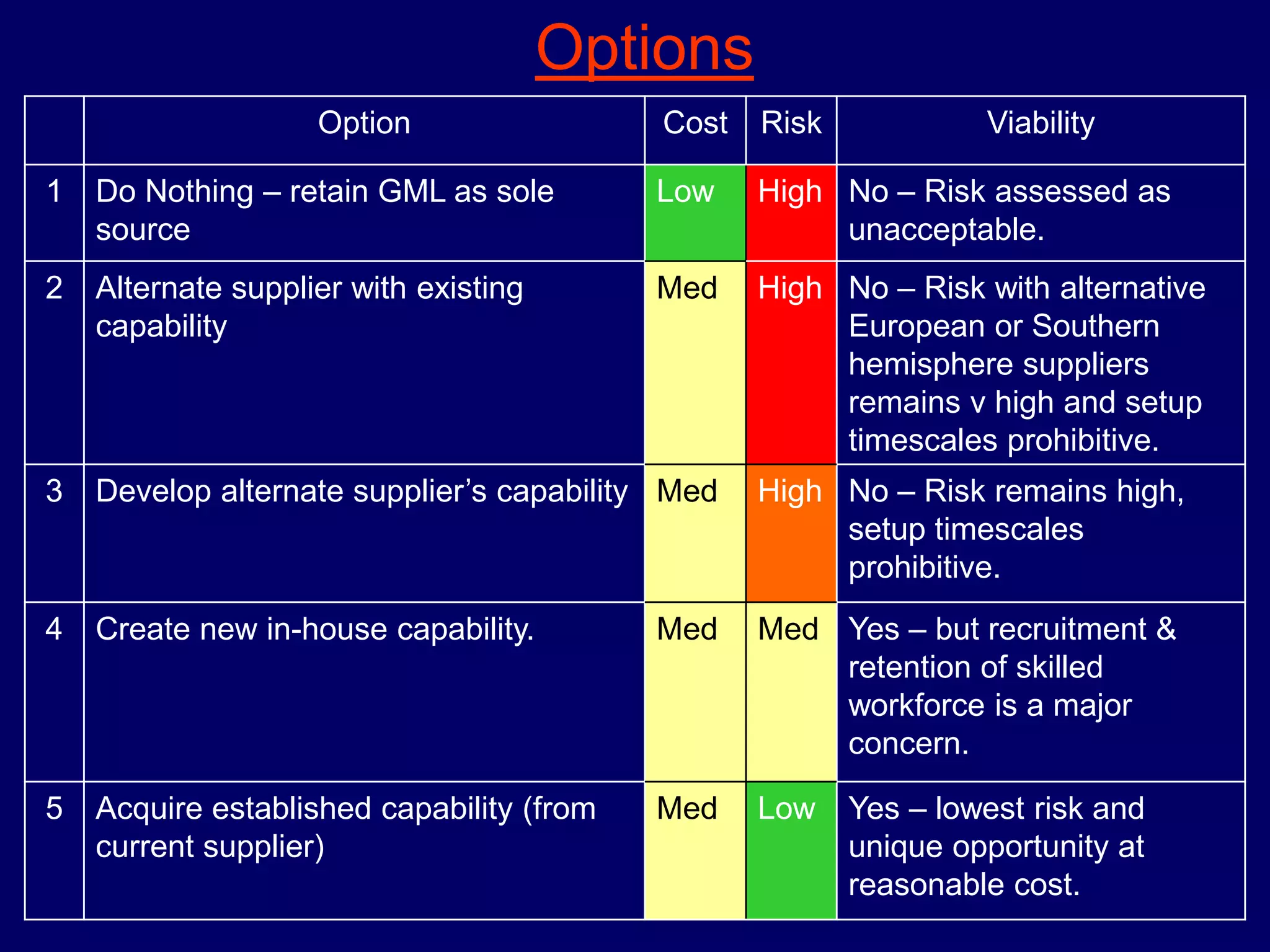

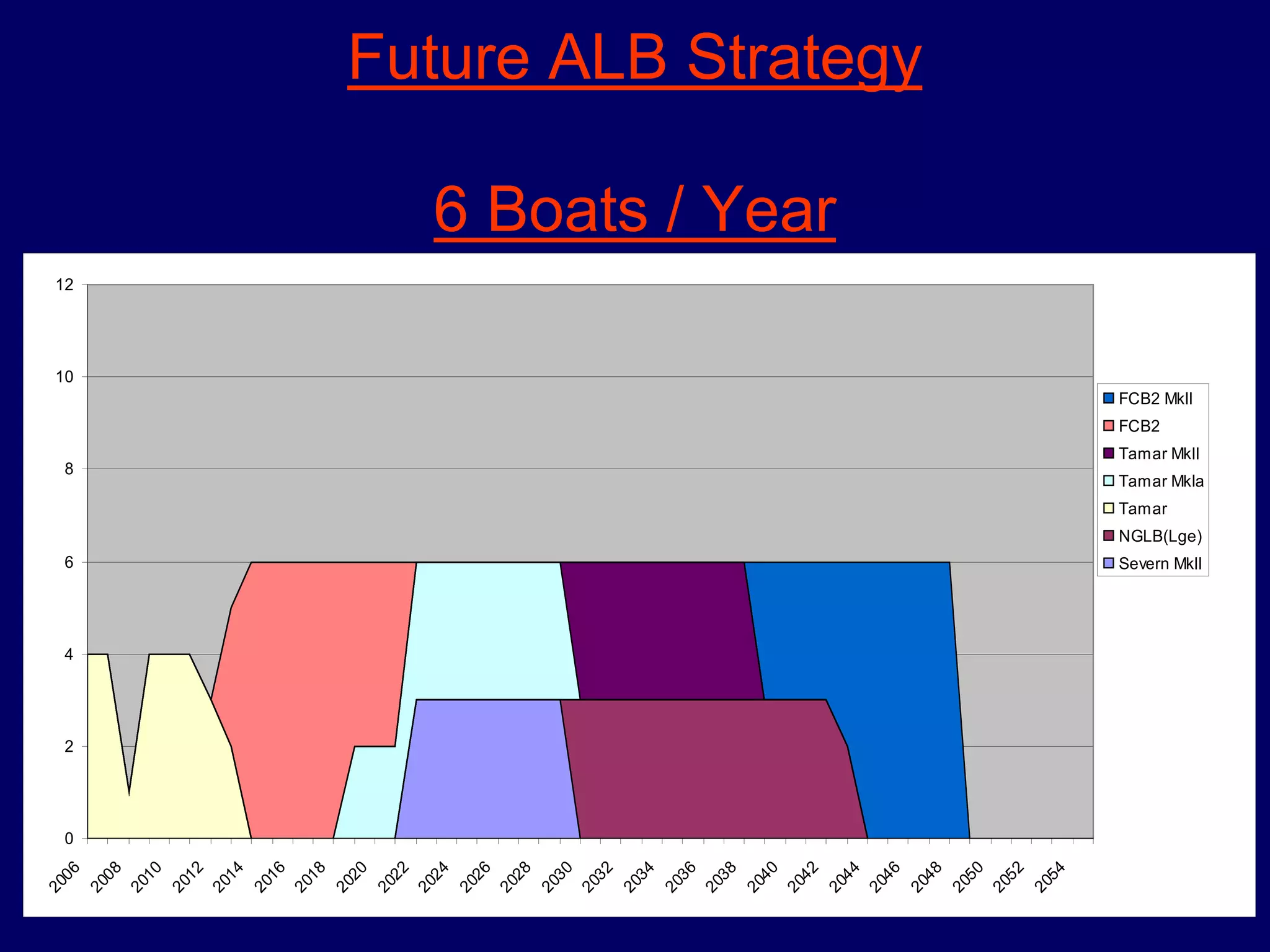

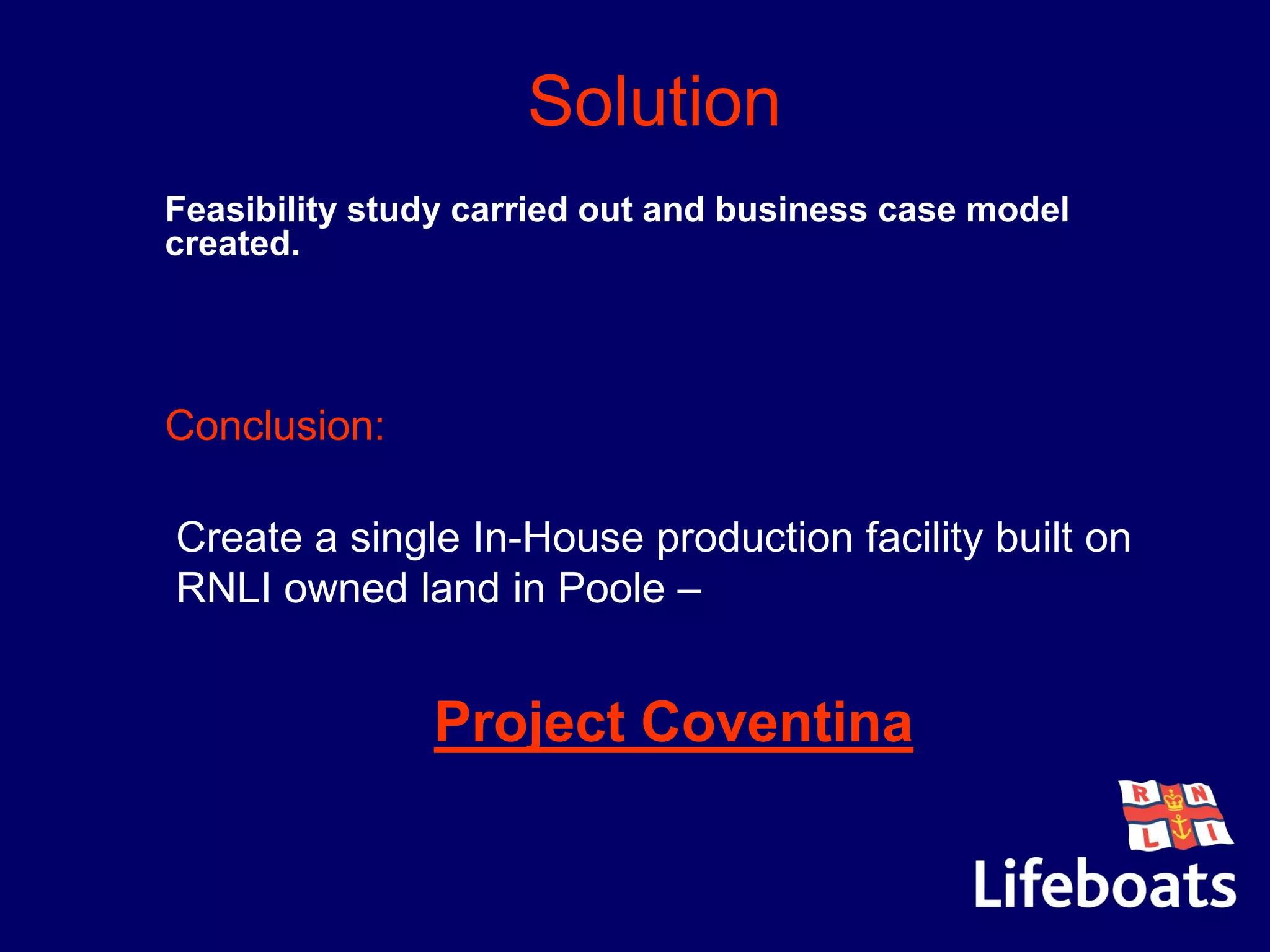

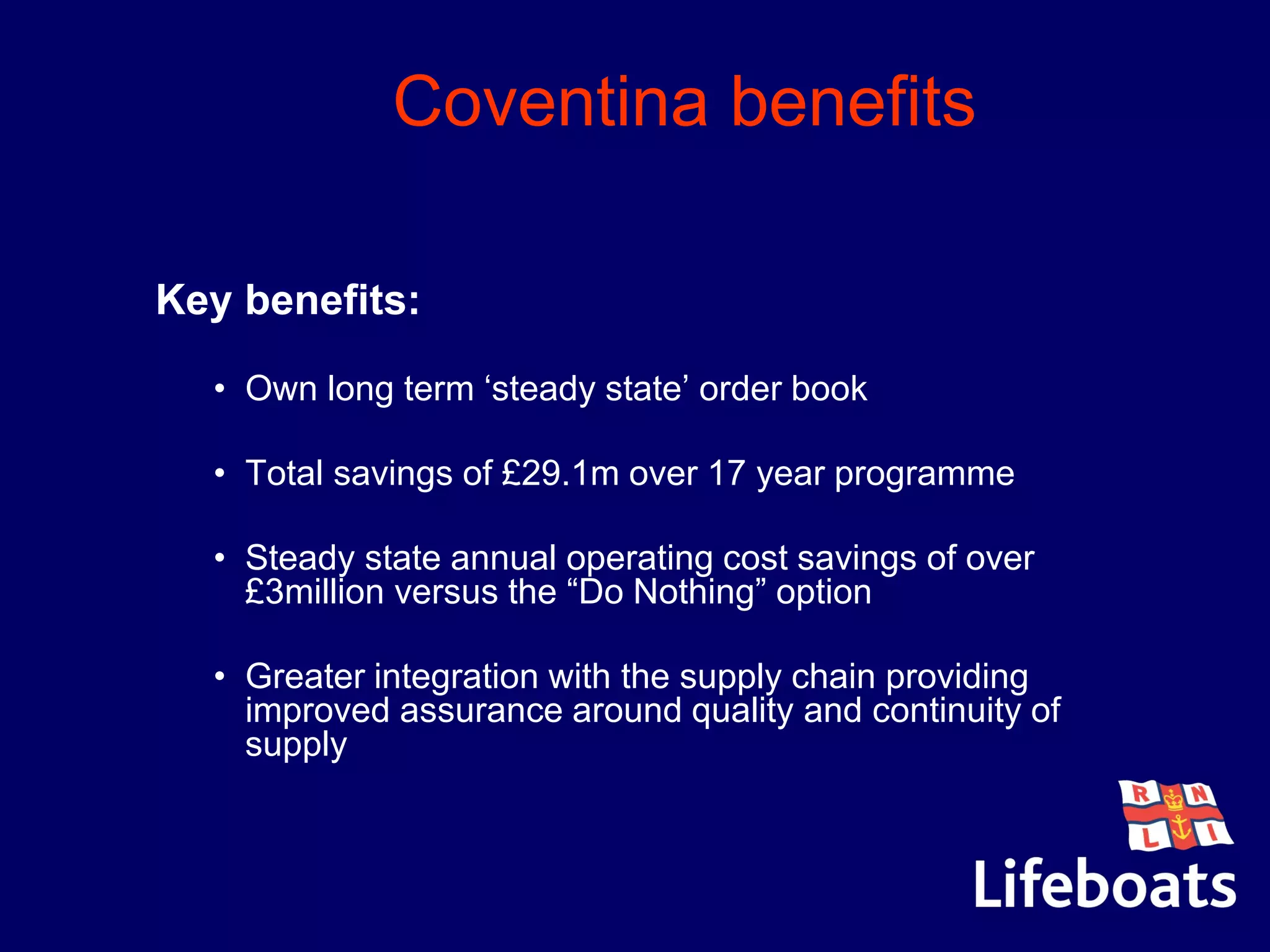

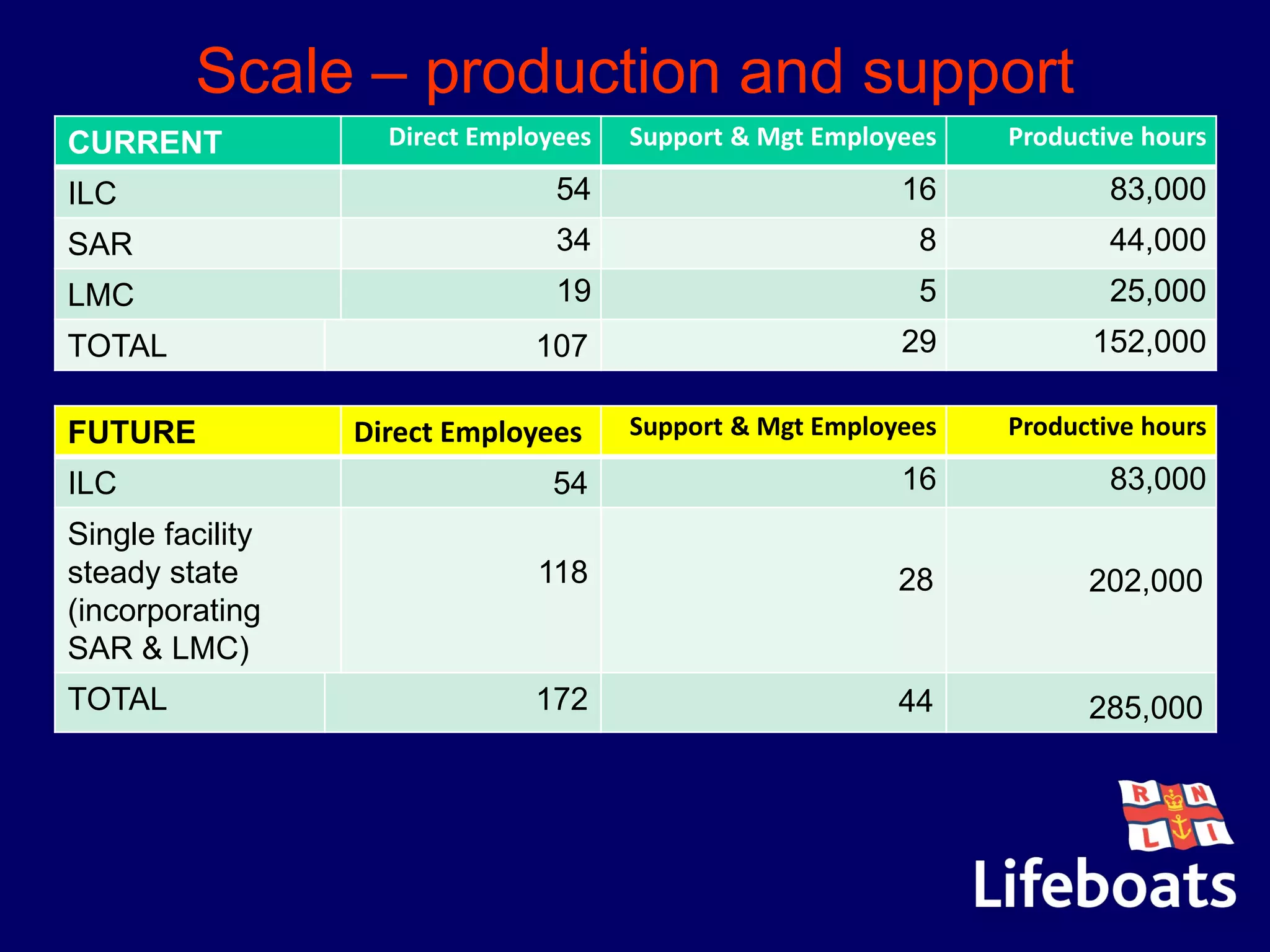

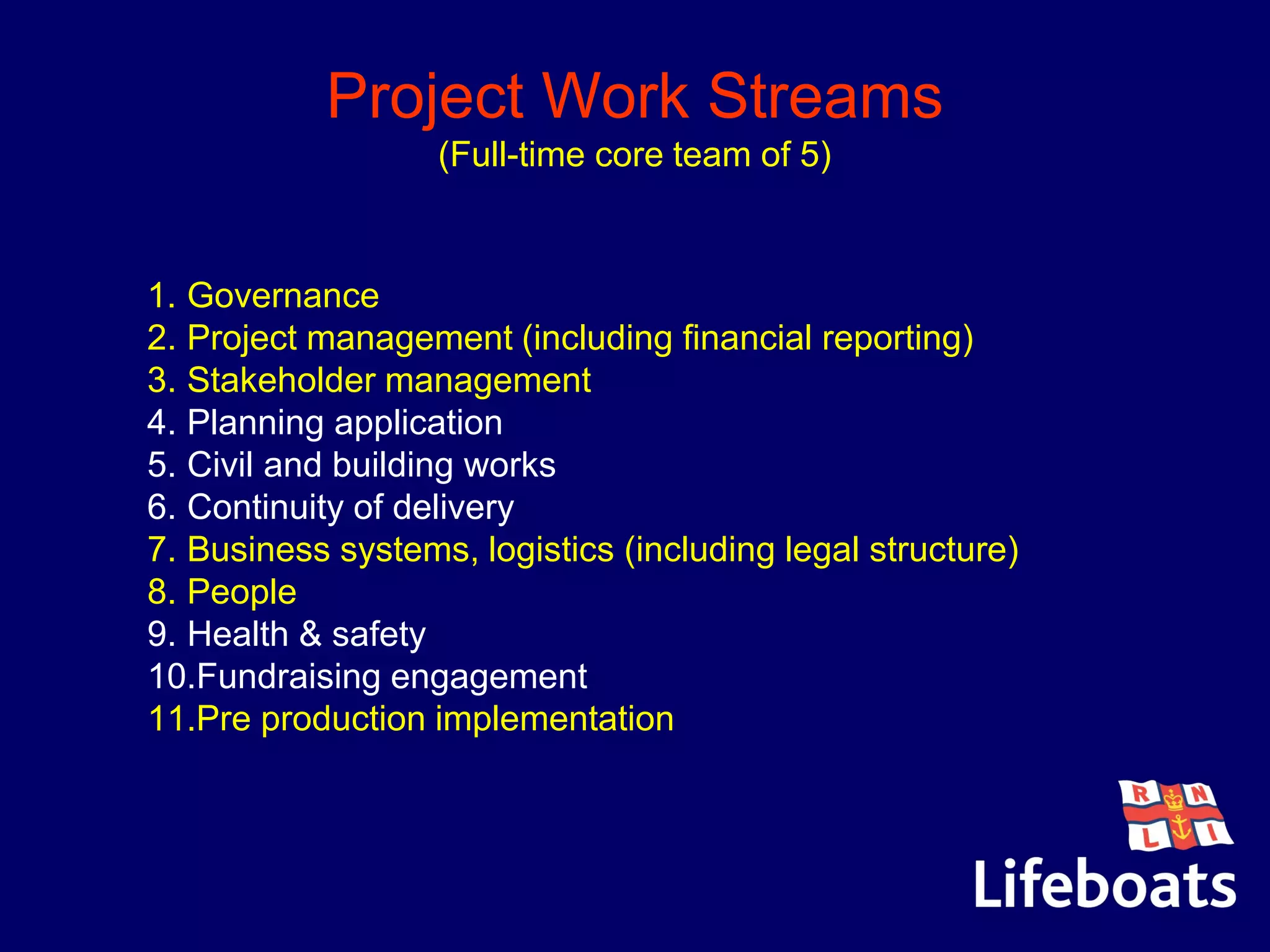

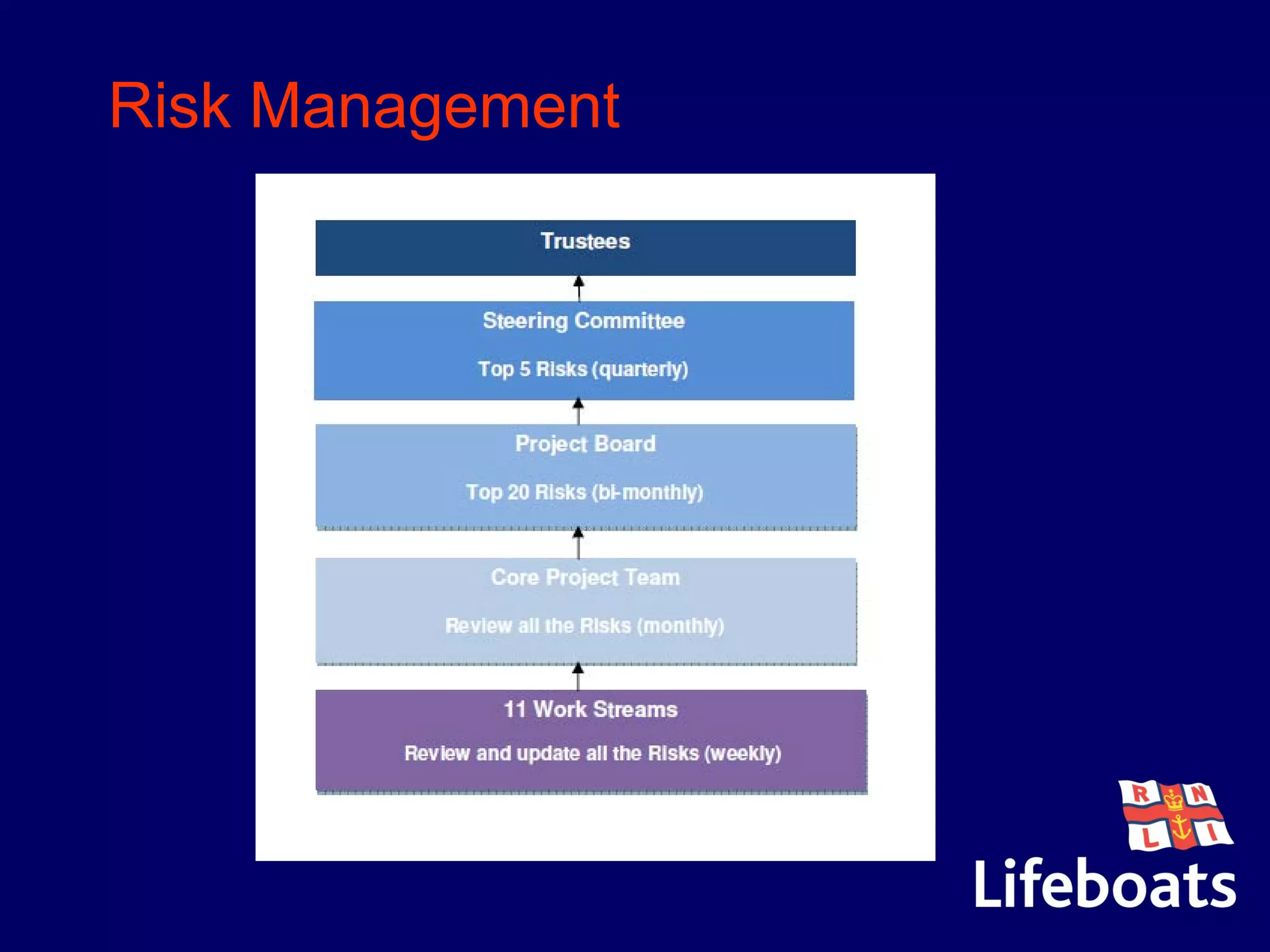

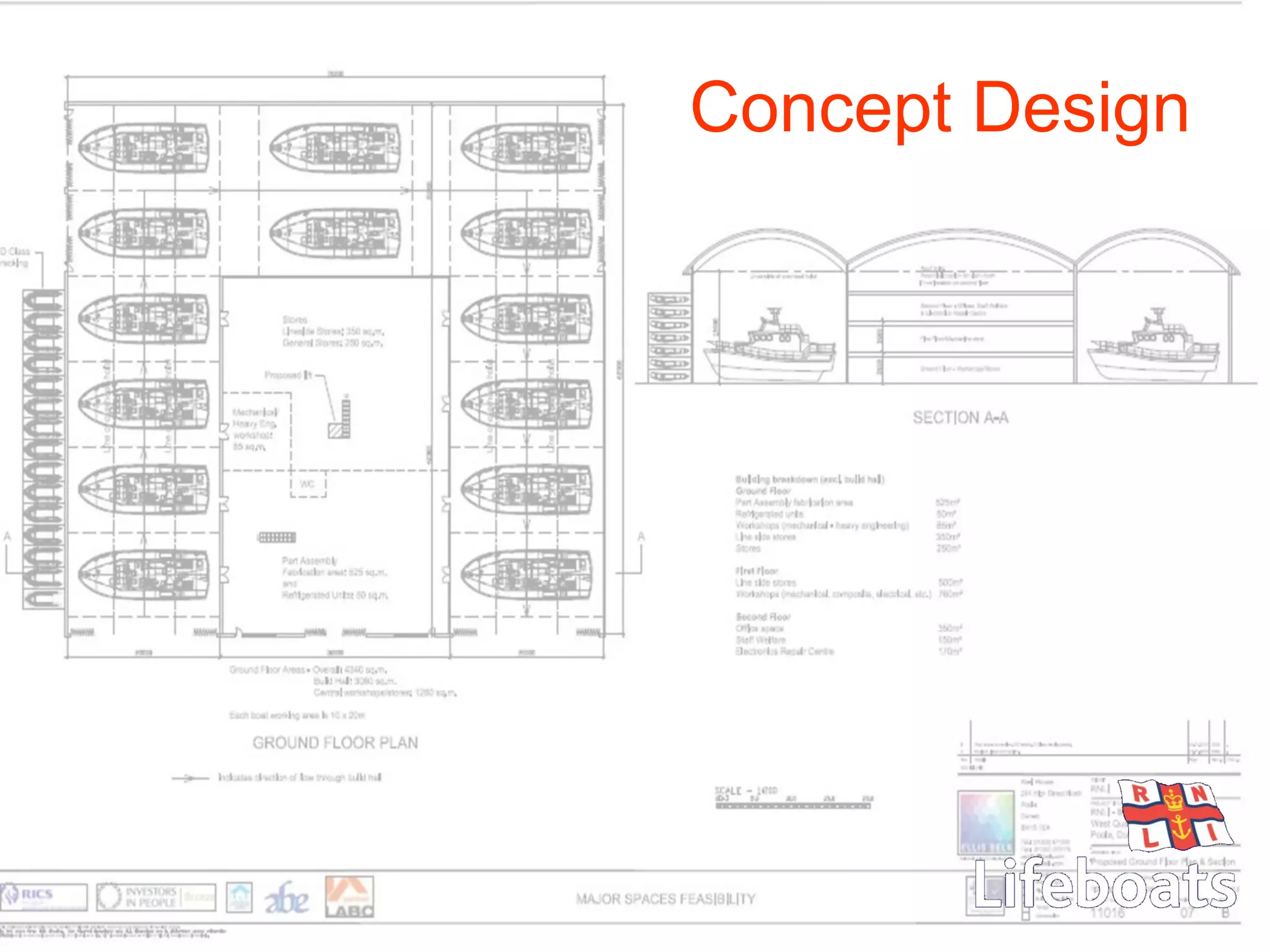

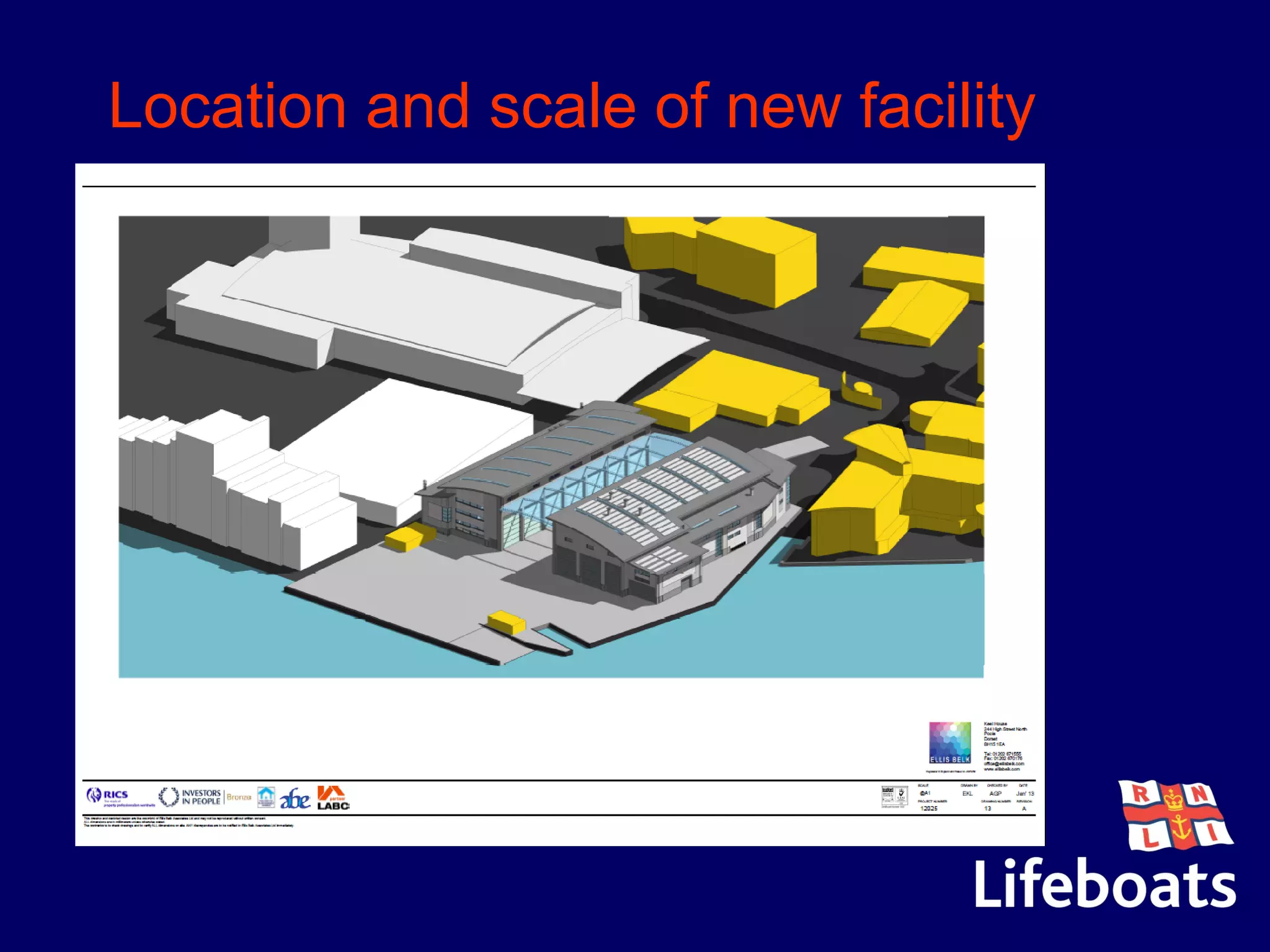

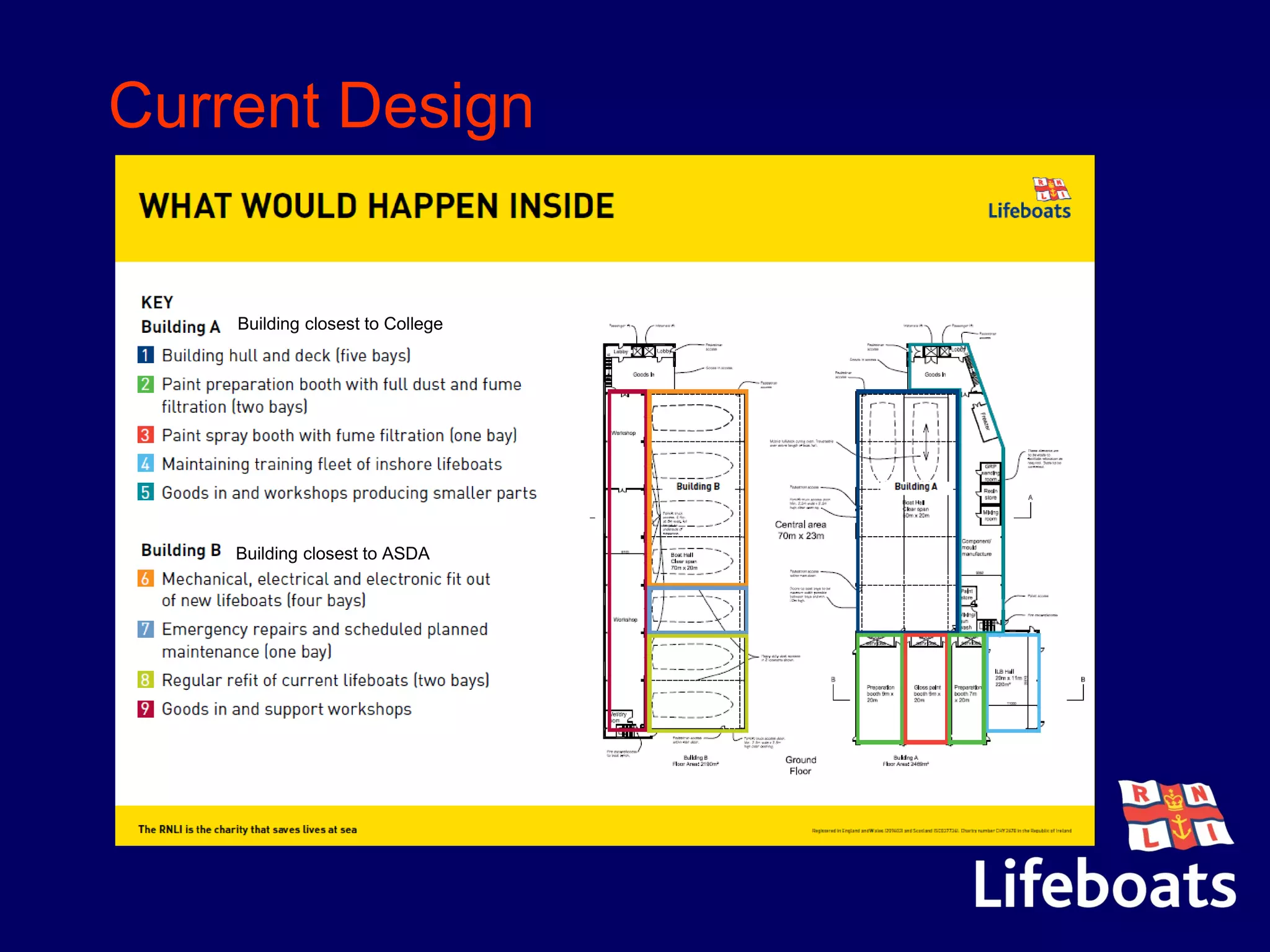

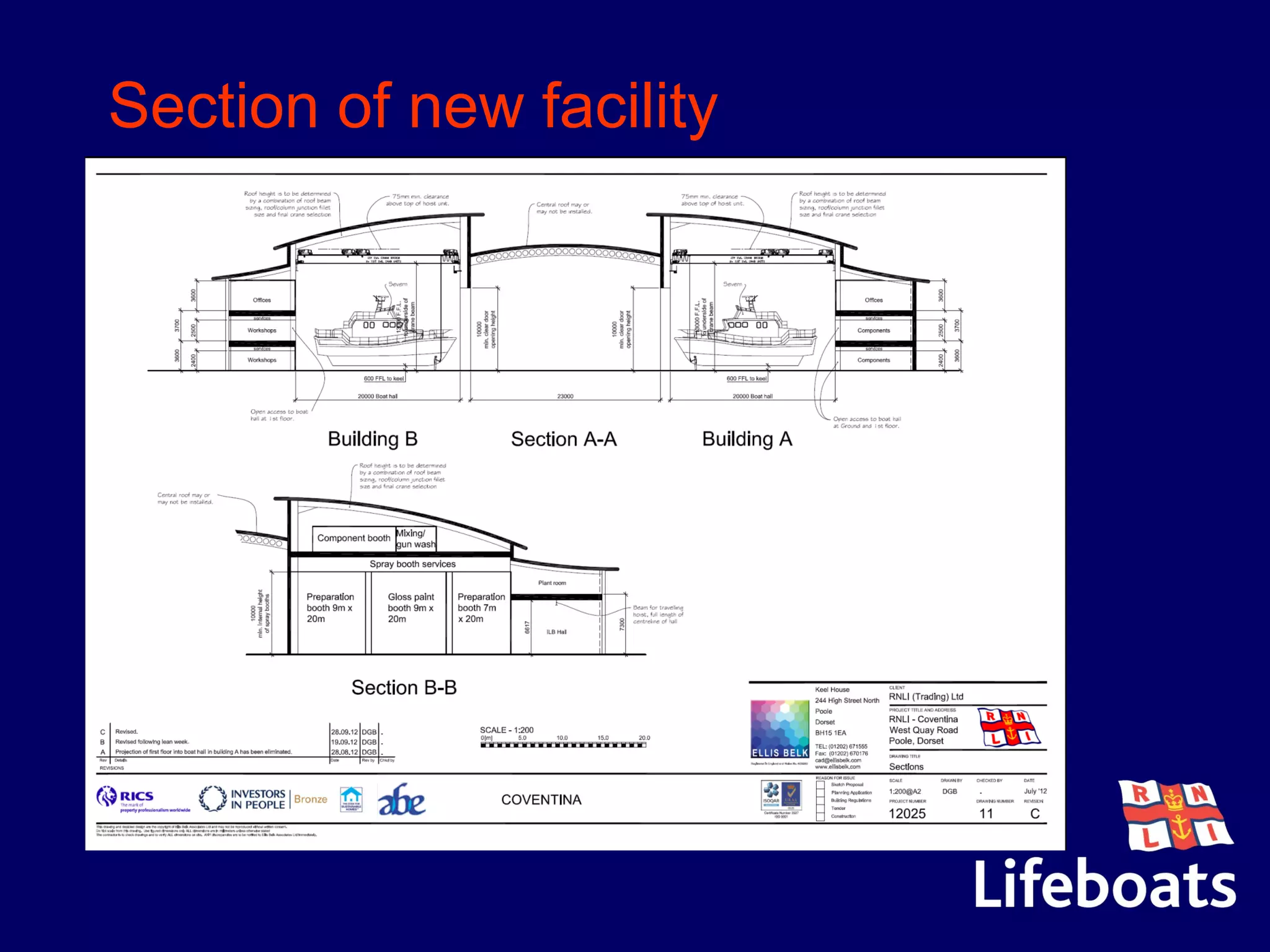

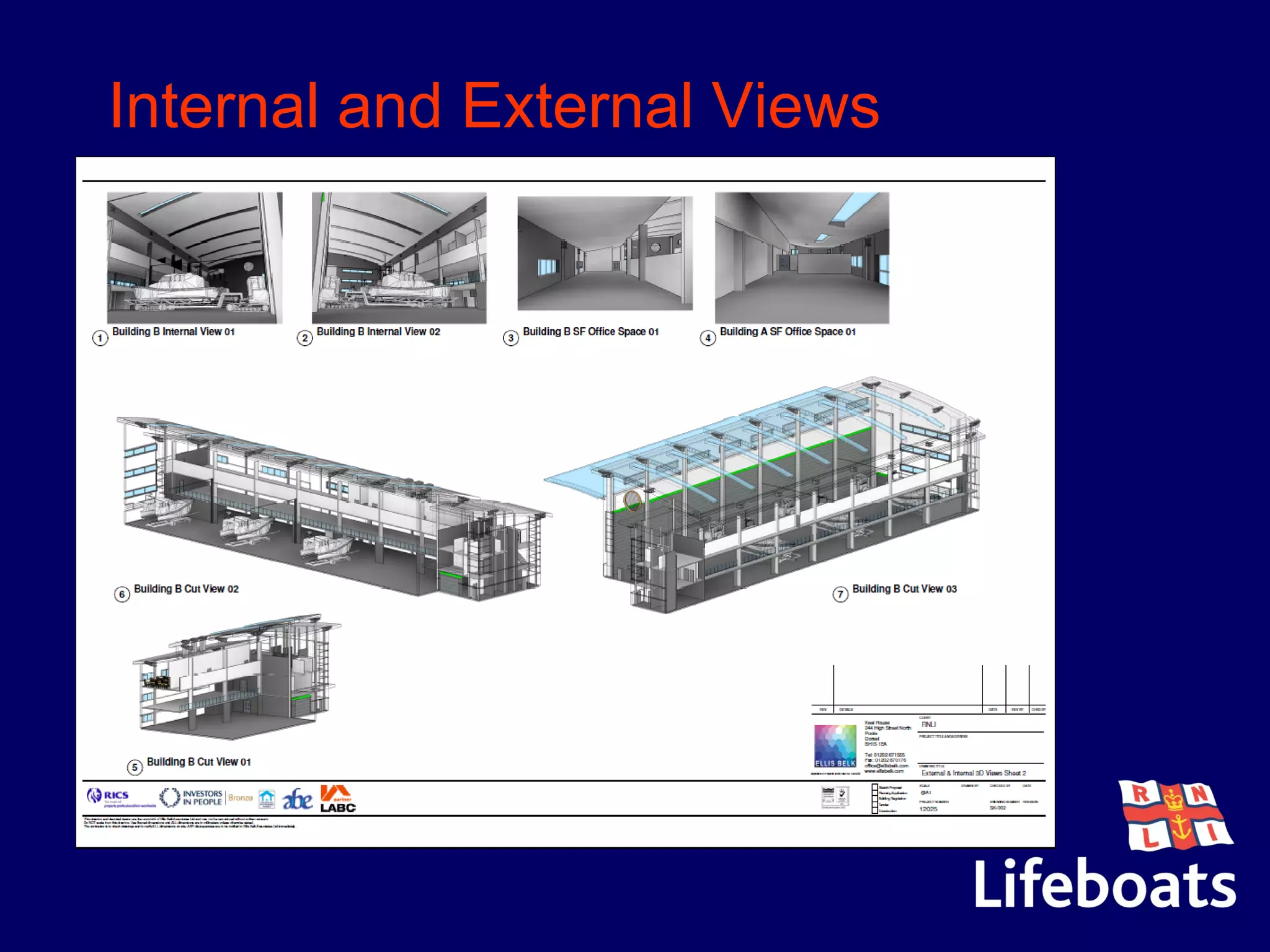

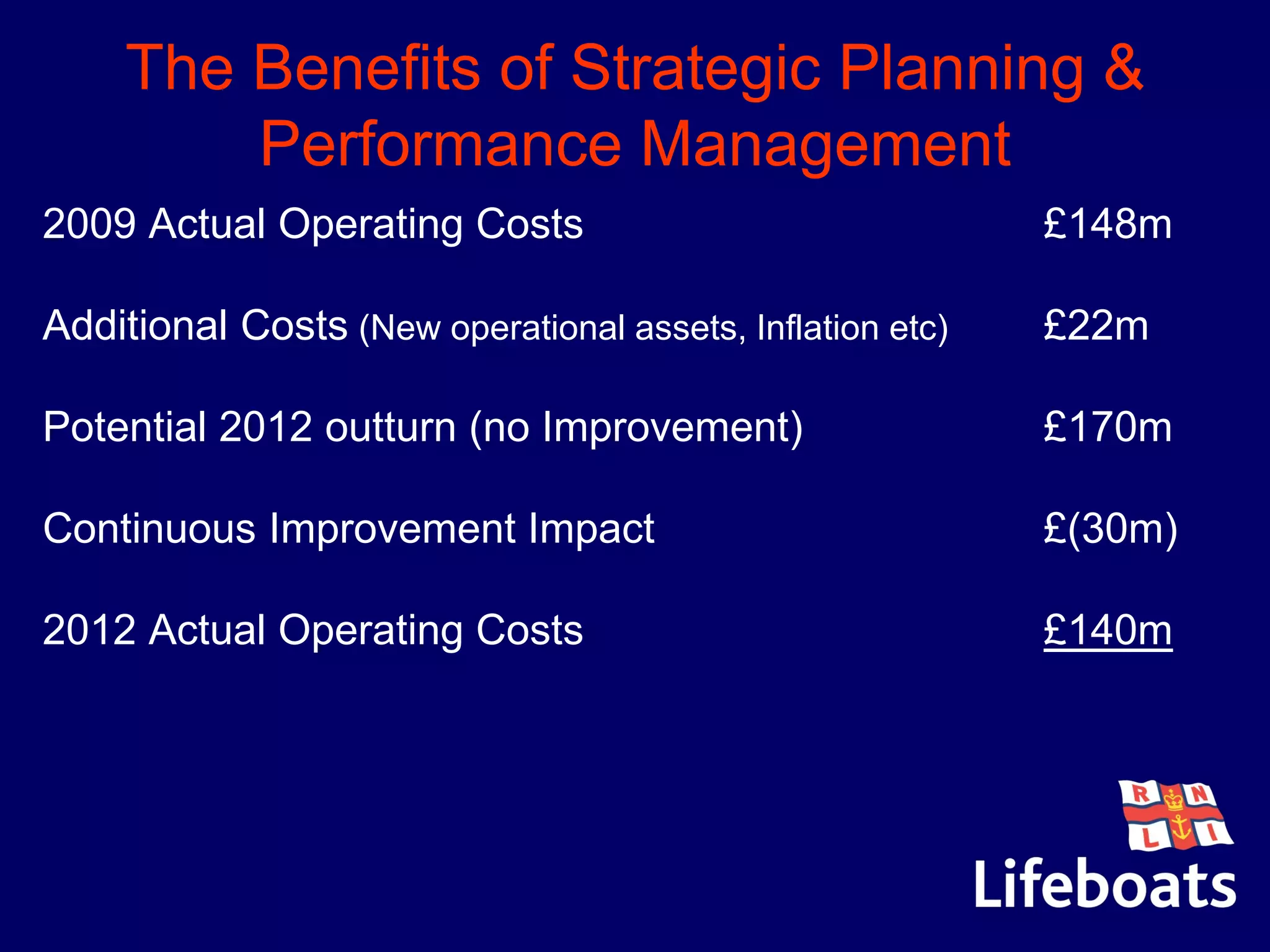

The presentation discusses the challenges of project management in the RNLI, focusing on issues such as demand planning, budget efficiency during a recession, and sustainability. It outlines the RNLI's unique structure as a volunteer-funded organization dedicated to delivering effective lifesaving services, while emphasizing the need for continuous improvement and innovation in design and maintenance. Key strategies include adopting lean practices, condition-based maintenance, and integrating design and production to enhance reliability and cost-effectiveness.