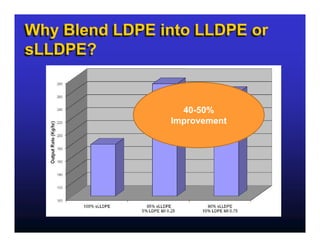

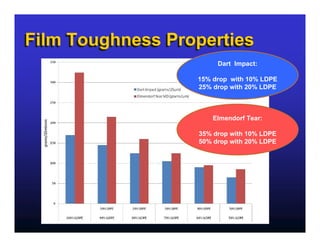

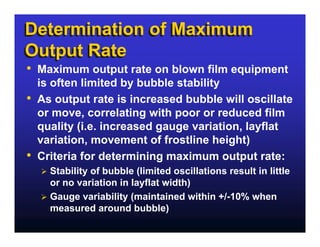

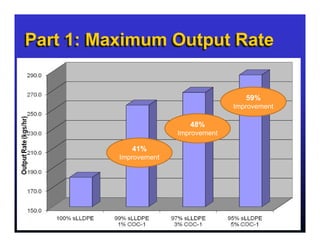

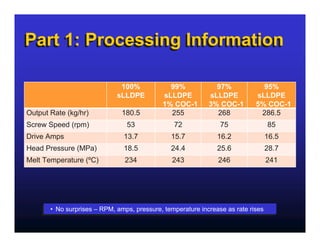

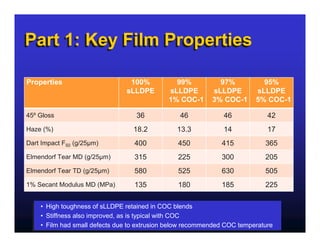

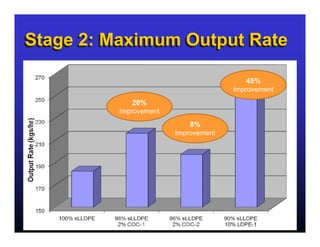

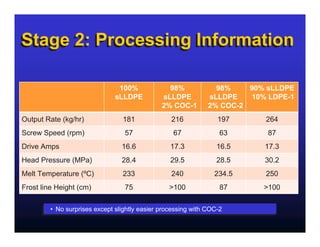

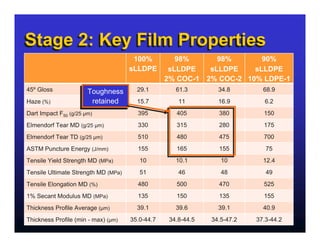

The document discusses a presentation on the blending of cyclic olefins in single-site LLDPE to enhance bubble stability and output rates in blown film extrusion, presented at the SPE International Polyolefins Conference. It details the experiments conducted, showing up to 59% improvement in maximum output rates and retention of film toughness properties due to the incorporation of cyclic olefin copolymers. The conclusions highlight the benefits of low-level blending with specific coc materials to achieve these results.