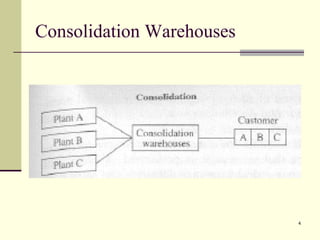

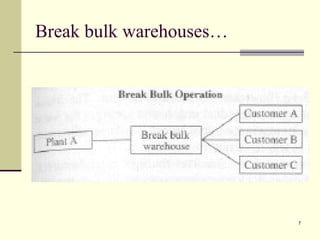

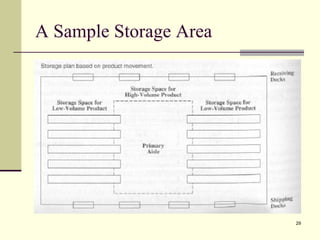

The document discusses various aspects of warehouse management. It describes warehouses as switching facilities rather than just storage facilities. It outlines benefits like consolidation, break bulk operations, processing/postponement, stockpiling, and service benefits like spot stocking, assortments, mixing, production support, and market presence. It also discusses design criteria like number of stories, height utilization, and product flow, as well as handling technology and storage plans as important operating principles.