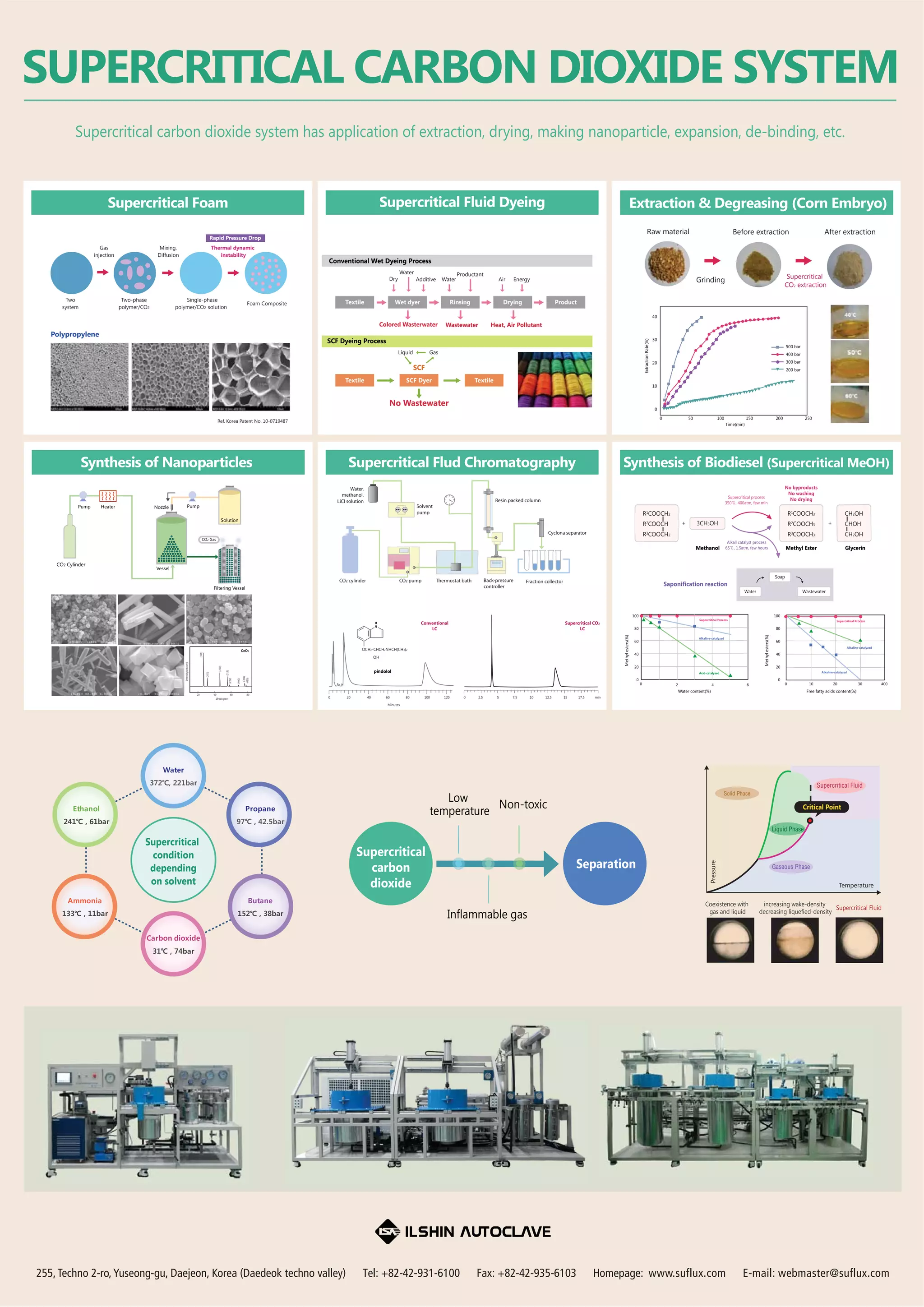

The document discusses the properties and applications of supercritical fluids, particularly supercritical carbon dioxide, highlighting its utility in processes such as extraction, drying, and dyeing. It details the critical points and conditions of various substances used in supercritical processes and mentions specific applications in synthesizing nanoparticles and biodiesel production. Additionally, it addresses environmental benefits like reduced wastewater and pollutants compared to conventional methods.