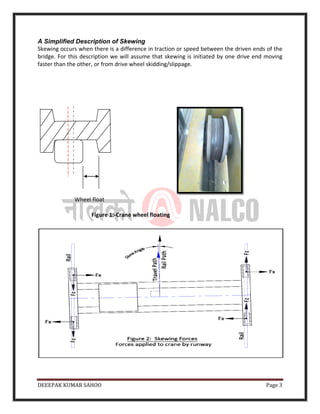

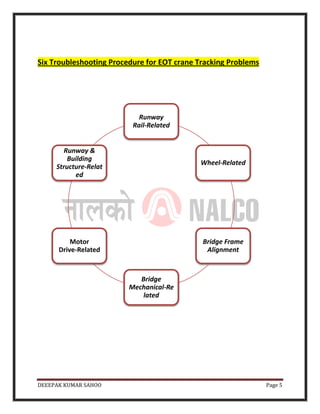

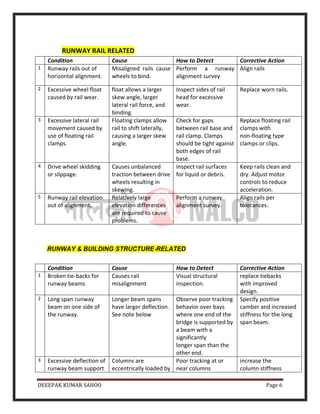

This document discusses the diagnosis and rectification of tracking problems in bridge cranes. It begins by describing common symptoms of tracking issues like frequent wheel replacements and broken tie-backs. It then provides a simplified description of how skewing occurs due to differences in traction between the driven ends of the bridge. The rest of the document outlines six troubleshooting procedures for identifying potential causes of tracking problems related to the runway, wheels, bridge frame alignment, bridge mechanics, motor drives, and runway/building structure. It concludes by describing a specific case of rectifying rail bar span issues on a 10MT EOT crane to address problems with the crane stopping in certain locations.