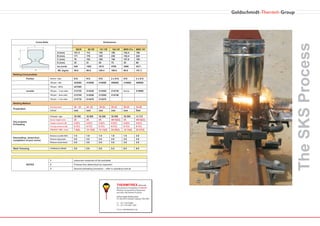

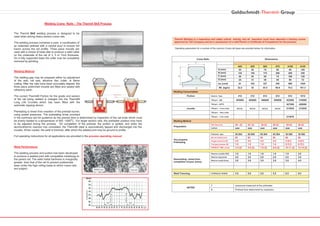

The document provides specifications for welding various sizes of crane rails using the Thermit SkS welding process. This process uses a three-piece preformed mould and extended preheating, followed by a central pour of molten steel, to ensure full fusion across the rail profile. Operating parameters like rail dimensions, welding consumables, preheating times and temperatures, and dismantling times are given for different rail types to achieve welds with compatible metallurgy to the parent rail.