- ASTM is a global organization founded in 1898 that develops voluntary consensus standards through technical expert committees. It has over 30,000 members from 150 countries.

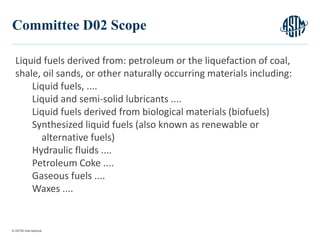

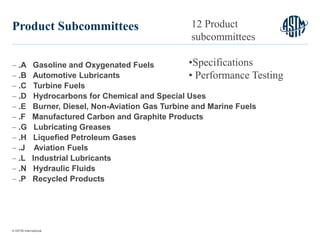

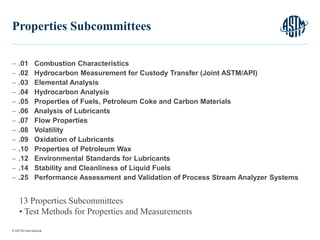

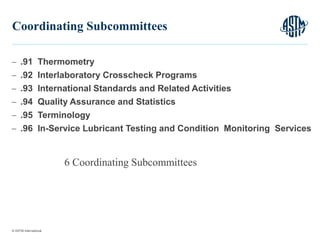

- Committee D02 is ASTM's largest committee, focused on petroleum, liquid fuels, and lubricants. It has over 800 standards developed by a structure of subcommittees and task groups.

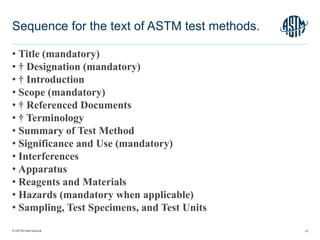

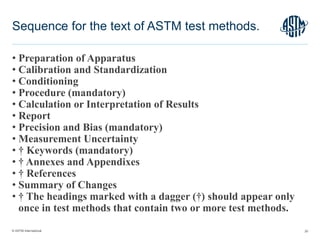

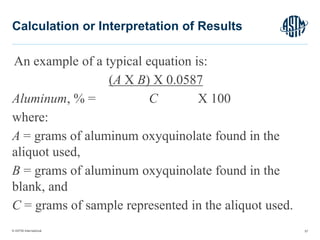

- ASTM test methods are concise procedures for determining material properties and constituents, and provide sufficient detail and precision for their intended uses.