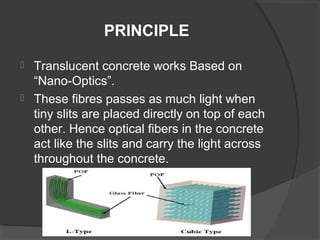

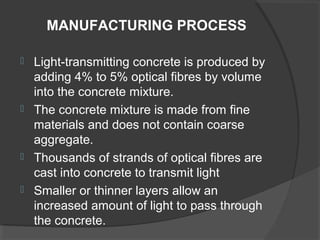

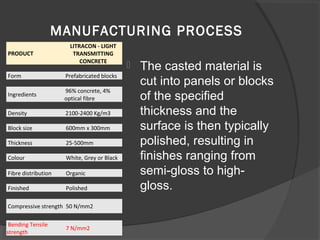

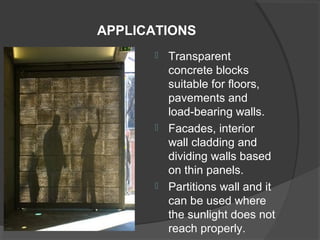

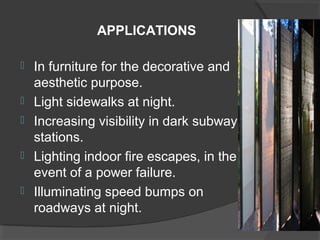

Translucent concrete, also known as transparent concrete or litracon, is a building material that allows light to pass through due to embedded optical fibers. The manufacturing process involves pouring layers of concrete interspersed with optical fibers, resulting in various applications such as facades, load-bearing walls, and decorative furniture. While it offers aesthetic and energy-saving benefits, the material is costly and requires skilled labor for production.