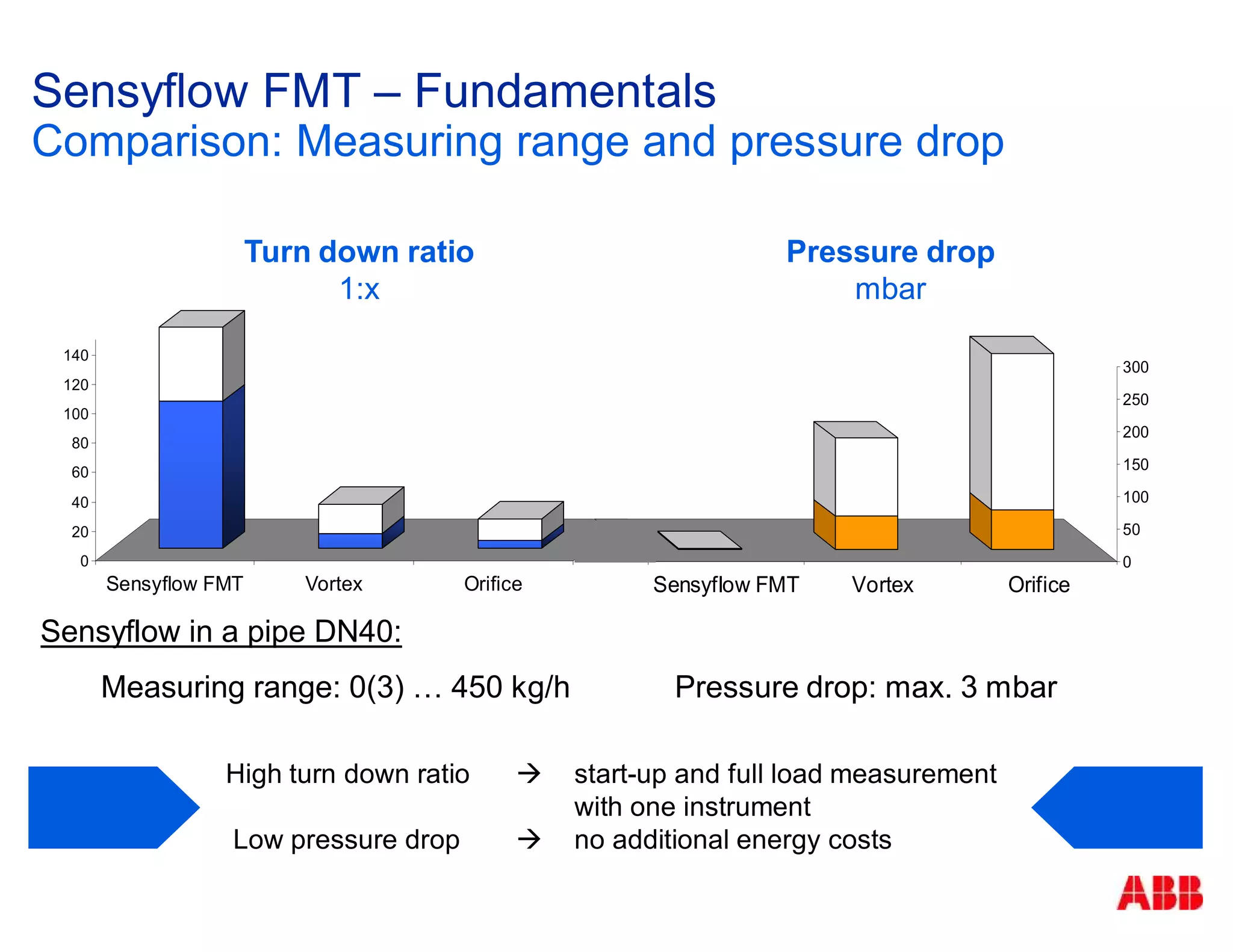

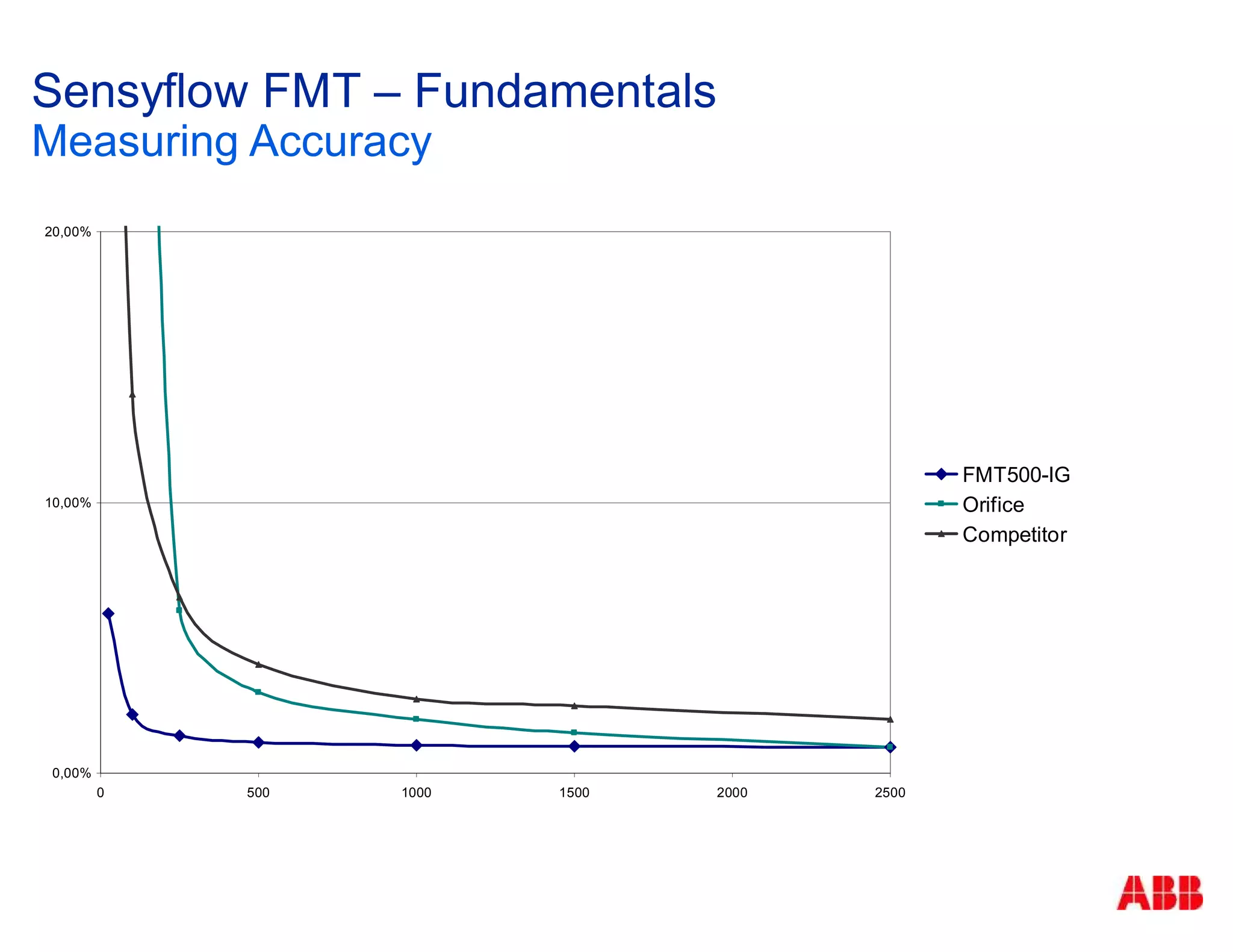

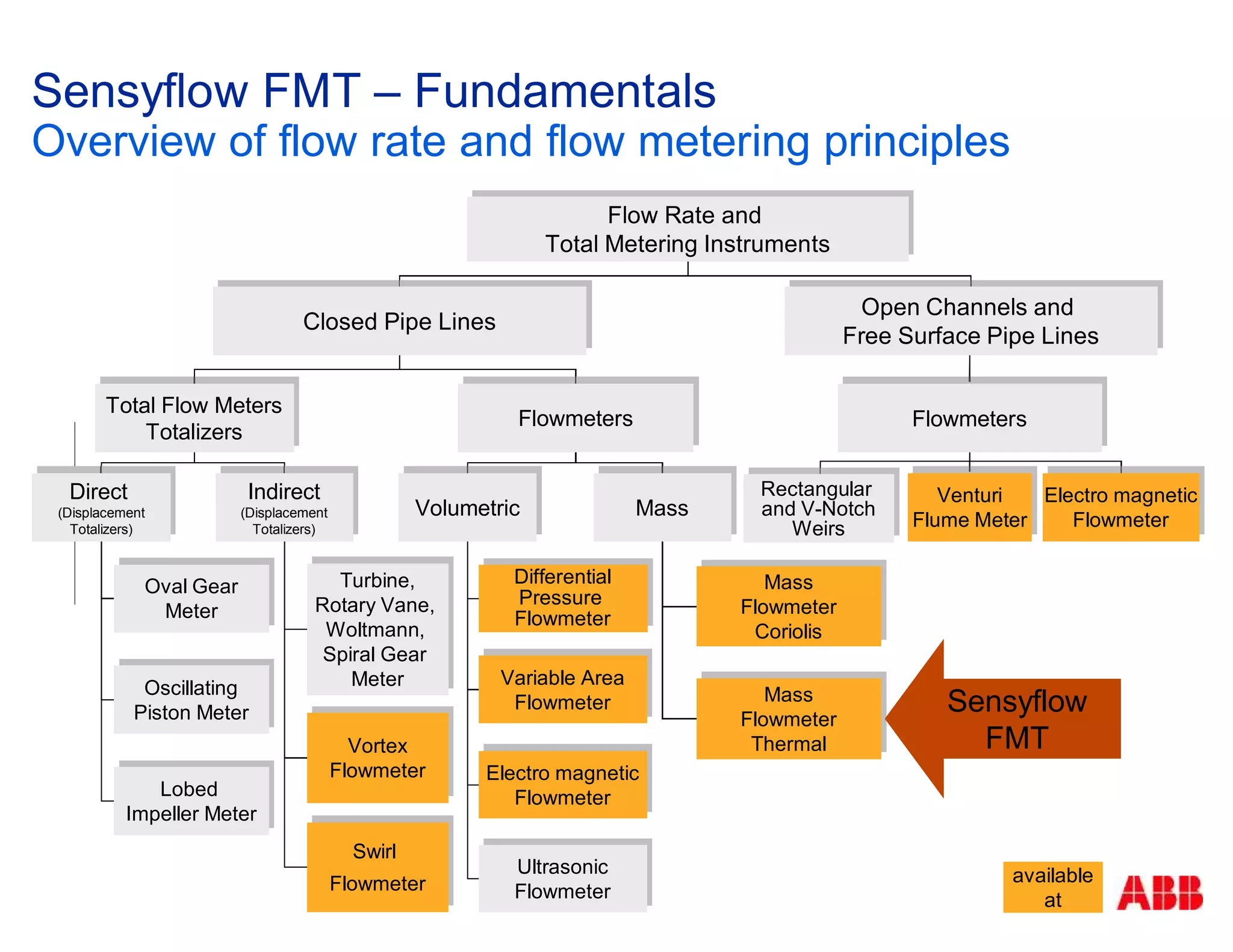

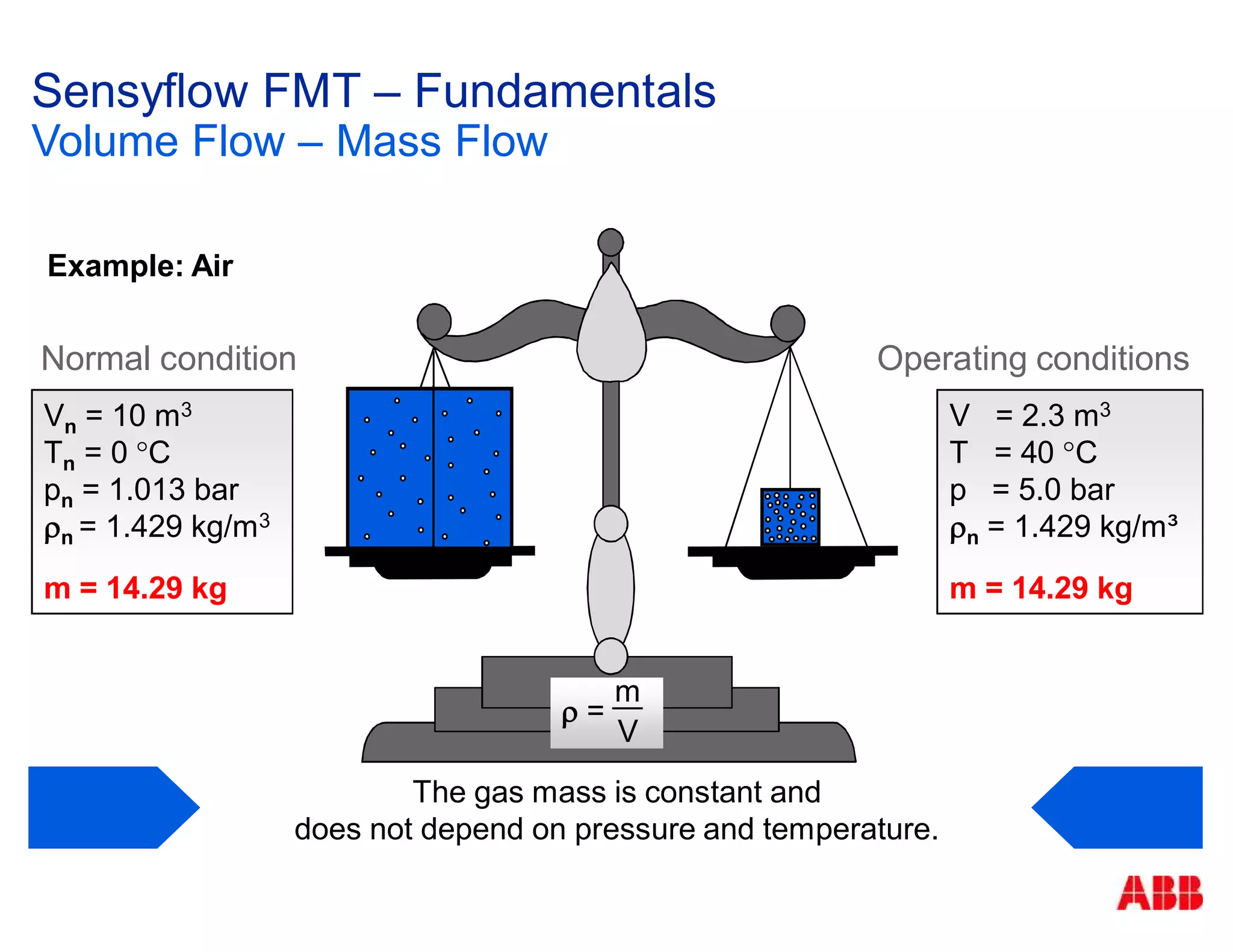

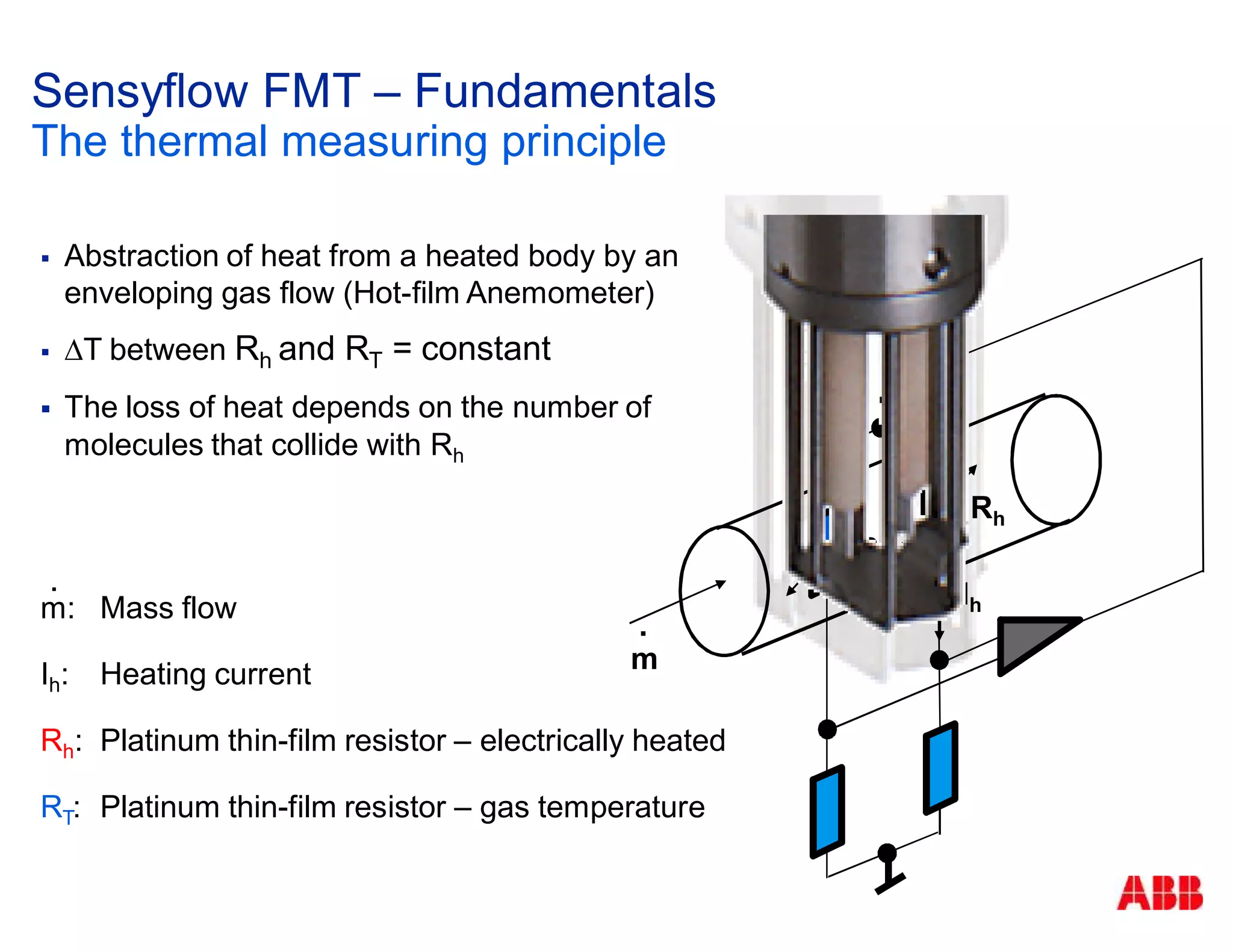

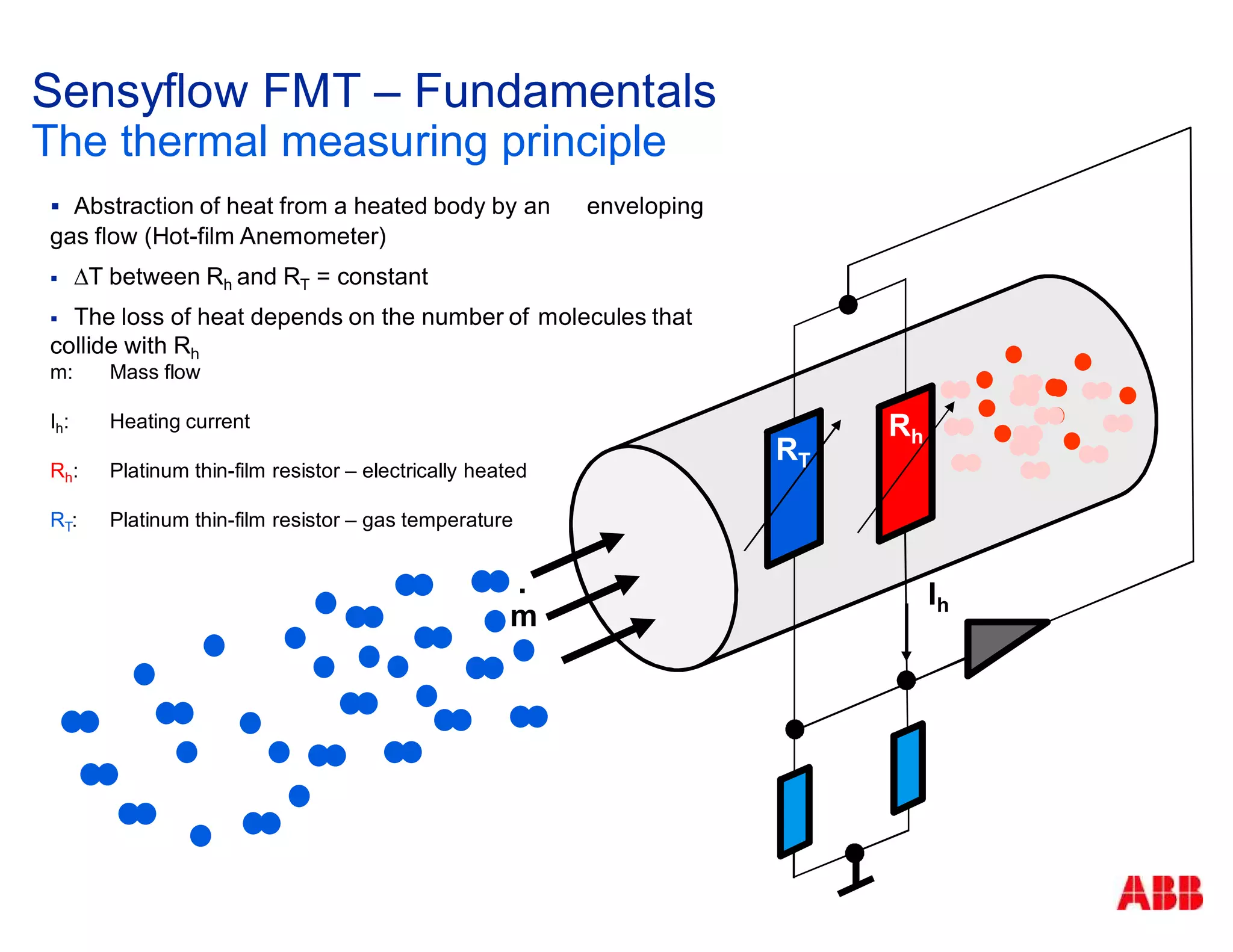

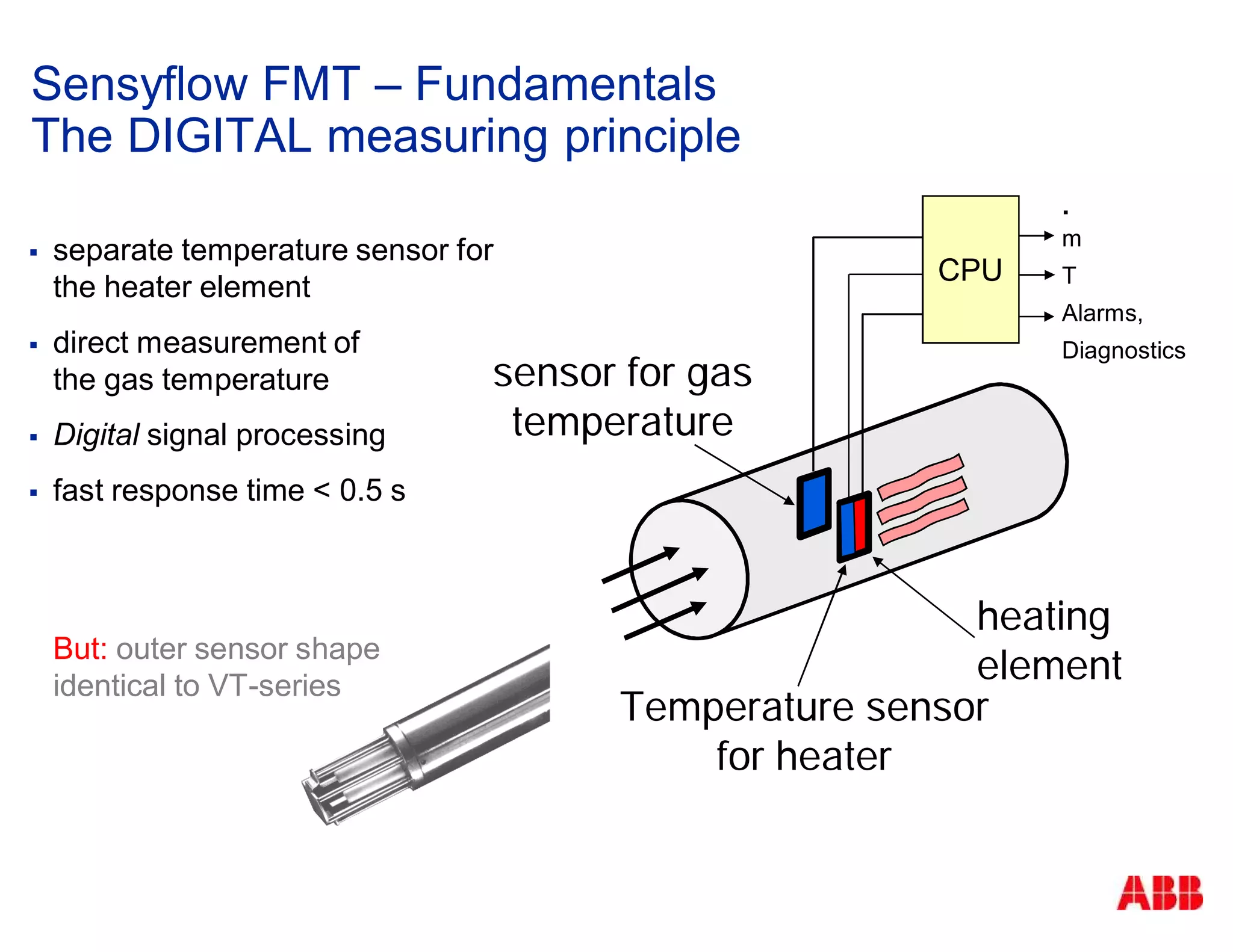

Thermal mass flowmeters like the Sensyflow FMT use the principle of heating a sensor element and measuring the heat loss to determine mass flow. The Sensyflow FMT has a wide measuring range, low pressure drop, and direct measurement of mass flow. It can be used for full load measurement and leakage detection with one instrument.

![100 200 300 400 500

.

m / [kg/h]

Ih / [mA]

300

400

500

410

Sensyflow FMT – Fundamentals

Characteristic curve

.

The heating current Ih is a measure for the mass flow rate m

For ambient air

in a 40 mm pipe

approx.

280 km/h

20 km/h](https://image.slidesharecdn.com/thermischemassadebietmeter-140730125306-phpapp01/75/Thermal-Mass-Flowmeter-ABB-N-V-8-2048.jpg)