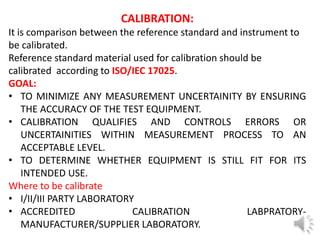

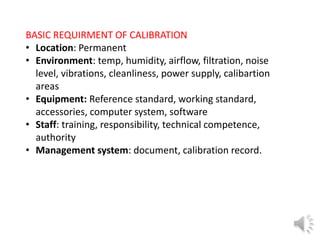

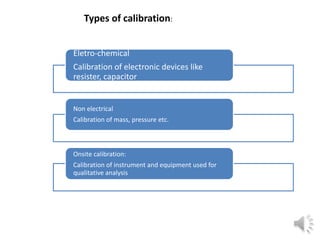

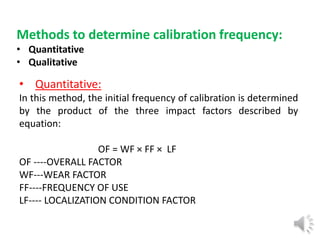

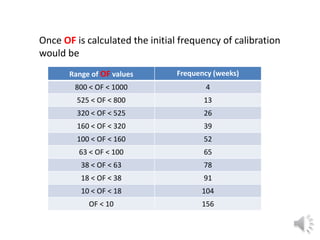

The document outlines the process and importance of calibration, which compares instruments against reference standards to minimize measurement uncertainty. It details the requirements for calibration, types of calibration, and factors influencing the frequency at which calibration should occur. Calibration is crucial for ensuring the accuracy, reliability, and consistency of test equipment, which ultimately supports product integrity and service quality.