@Resume-Pravinkumar sadare@

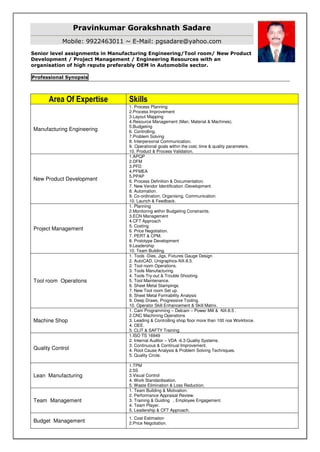

- 1. Pravinkumar Gorakshnath Sadare Mobile: 9922463011 ~ E-Mail: pgsadare@yahoo.com Senior level assignments in Manufacturing Engineering/Tool room/ New Product Development / Project Management / Engineering Resources with an organisation of high repute preferably OEM in Automobile sector. Professional Synopsis Area Of Expertise Skills Manufacturing Engineering 1. Process Planning 2.Process Improvement 3.Layout Mapping 4.Resource Management (Man, Material & Machines). 5.Budgeting 6. Controlling. 7.Problem Solving 8. Interpersonal Communication. 9. Operational goals within the cost, time & quality parameters. 10. Product & Process Validation. New Product Development 1.APQP 2.DFM 3.PFD 4.PFMEA 5.PPAP 6. Process Definition & Documentation. 7. New Vendor Identification /Development. 8. Automation. 9. Co-ordination, Organising, Communication. 10. Launch & Feedback. Project Management 1. Planning 2.Monitoring within Budgeting Constraints. 3.ECN Management 4.CFT Approach 5. Costing. 6. Price Negotiation. 7. PERT & CPM. 8. Prototype Development 9.Leadership 10. Team Building. Tool room Operations 1. Tools -Dies, Jigs, Fixtures Gauge Design 2. AutoCAD, Unigraphics-NX-8.5. 2. Tool room Operations. 3. Tools Manufacturing. 4. Tools Try-out & Trouble Shooting. 5. Tool Maintenance. 6. Sheet Metal Stampings. 7. New Tool room Set up. 8. Sheet Metal Formability Analysis 9. Deep Draws, Progressive Tooling. 10. Operator Skill Enhancement & Skill Matrix. Machine Shop 1. Cam Programming – Delcam – Power Mill & NX-8.5 . 2.CNC Machining Operations 3. Leading & Controlling shop floor more than 100 nos Workforce. 4. OEE. 5. CLIT & SAFTY Training. Quality Control 1.ISO TS 16949 2. Internal Auditor – VDA -6.3 Quality Systems. 3. Continuous & Continual Improvement. 4. Root Cause Analysis & Problem Solving Techniques. 5. Quality Circle. Lean Manufacturing 1.TPM 2.5S 3.Visual Control 4. Work Standardisation. 5. Waste Elimination & Loss Reduction. Team Management 1. Team Building & Motivation. 2. Performance Appraisal Review. 3. Training & Guiding , Employee Engagement. 4. Team Player. 5. Leadership & CFT Approach. Budget Management 1. Cost Estimation 2.Price Negotiation.

- 2. Employment Chronicle 1. Bajaj Auto Ltd., Aurangabad , Maharashtra - Aug’97 to Nov’2012 (15 Yrs -3 Months) Assistant Manager –Planning, Design, Manufacturing Engineering, and Tool room Operations. 2. Setco Automotive Ltd., Vadodara, Gujarat - Nov’2012 to Dec-2015 ( 3 Yrs ) Senior Manager - Tool Engineering Dept. 3. Krupa Technologies, Aurangabad, Maharashtra – Jan’2016 to Till date Senior Manager - Manufacturing Engineering Dept. Manufacturing Engineering – 1> Reengineering process -in case of petrol tank outer for Patina & Boxer Model by developing non- conventional draw process with Polyurethane Punch resulted in 90 Rs saving / Petrol Tank of Boxer 2 Wheeler. (Annually Saving 3Cr +.) 2> VAVE - Redesigning Platina 2 WH Petrol Tank inner draw die for reduction in draw height resulted in Material Saving 20 Rs per Petrol Tank of Platina 2 Wheeler. (Annually Saving 1Cr +.) 3> Process Improvement – For 2 Wh Platina Model Silencer, Auto blanking die successfully introduced to one set blanks of Cone, Body & Baffles resulted in saving near to 1Cr. 4> Quality Improvement – In 3 Wheeler Rickshaw, Windshield Aperture Welding improvement by Reverse engineering of all child components corrected with spring back Analysis & Gap Analysis. 5> PokaYoke & Kaizen - o Error Proofing , Operation combination, Layout Optimisation, Yield improvement and process streamlinsation in 3wh & 2 Wh Chassis Assembly Line . 6>Tool room SAP coordinator for – PP module 7>Budgeting, Price Negotiation in Project – 3 Wh RE Facelift, 4Wheeler. 8>Established machining processes and utilized the latest tooling technologies to reduce lead time and increase throughput efficiency. Design + 3D Modelling & Cam Programming 1>Initiated design of Single Piece petrol tank Outer Draw design 1st time in India. 2>significantly carried out 3D Modelling and Cam Machining Single Piece petrol tank Outer Draw. 3>Ascertained the requirements of development of Dies, jigs & fixtures, GD&T for 2wh, 3wh&4wh new model development. Heavy Duty & Precision CNC Machining Operations 1>Over sawed machining of the Heavy Duty Press Tool Dies, CNC Fixtures for Engine Parts, Pressing Fixtures, and Welding Fixtures & Gauges for 2wh and 3wh. 2>Deft in CNC Machine operations like Droop & Rein Copy CNC milling machine , Boko & Maho CNC milling machine with Fidia Controller as well as precision m/cs like Wire cut , EDM ,Grinding . 3>Steered efforts in strategizing techniques for maximum utilization of manpower/machinery. 4>Managed 70+ employees and 5 Supervisors. Lean Manufacturing :- 1>Provided Leadership & support to implement & sustain TPM, ISO-TS-16949 etc. 2>Applied World class Manufacturing Techniques like Kaizen, Pokayoke, Kanban JIT, Gemba, Muda, PDCA. 3>Leaded & managed a variety of improvement activities which are aimed at removing no- value added activities therefore reducing cost, improving delivery & building customer satisfaction. Project Management :- 1>Conducted DFM of Sheet Metal Parts in CFT along with R&D, ME and Quality. 2>Conducted PFD, PFMEA, Control Charts, and Inspection Standards etc. in CFT. 3>Measured Project Performance using appropriate tools & techniques. 4>Ensured all Projects are delivered on time within scope and the Budget. 5>Performed Risk Management to minimize Project risks. 6> Cost effective Proto parts development for Clutch Disc. Key Result & Notable Highlights in Bajaj Auto Ltd: Key Result & Notable Highlights in Setco Automotive Ltd:

- 3. New Tool room Setup :- 1>Establishment of New Tool room and managing tool room functions in Setco Automotive Ltd. 2>Budgeting, Layout Mapping, Machinery Purchasing, Man power set up. 3>Travelled to China, Taiwan for Buy off, Testing, Inspection of VMC & CNC Wire cut machines. Process Re- Engineering -Converted Gun riveting operations of 280,310,430 clutches cover & Disc assembly into Press tool achieved productivity improvement by 3 times. Productivity Improvement - Converted all cushion segment tools into Progressive on auto coil feeder resulting production ramp up by 4-5 times on high speed 60 spm press. Error proofs - in all types of retainer plate forming tools resulting 100% Error Proofing. New Product Development - Leaded & Developed clutch 170, 280,430 Volvo in Sheet Metal Commodity. Vendor Selection & Up gradation. Certified Internal Auditor for VW group –Quality standard VDA6.3. Reduced repair costs and cycle time by streamlining the repair processes, standardizing operations, and implementing new technology repair processes. Noted Dies & jigs, Fixture related constraints during initial events & planning countermeasures before mass production. PPAP - Co-ordinated production trial runs of fixtures and sheet metal dies as per customer with cross functions. Ensured complete in-process quality control and continuous improvement in process capabilities. (Clutch disc riveting operations, Welding Fixtures with Pokayoke & Sensors). Improved tooling quality by adaptation of world class manufacturing techniques & standardisation. Co-ordination between internal customer for quality issues resolution. Team Management 1>Leading, mentoring & monitoring the performance of team members to ensure efficiency in process operations and meeting of production targets. 2>Creating and sustaining a dynamic environment that fosters development opportunities and motivates high performance amongst team members 3>Controlling & Guiding function, conducting performance appraisal reviews. Head Manufacturing Engineering – Process Planning & Established Process Parameter for Heavy Fabrication for Cattle Farm Products & exported under “MAKE IN INDIA “Campaign. Process Streamlined - Effectively streamlined Stainless steel Fabrication Line by reducing Motion Loss, Minor stoppage, Setting time. Productivity Improvement:-Increased throughput 30% without increasing floor space or manpower through application of Lean, 6σ and employee engagement. On Time Delivery:-Improved on time delivery from 56% in Jan 2016 to 91% December 2016. Process Capability Enhancement by adding Pokayoke ,Correcting Welding Fixture & Control Plan . Developed and implemented engineering team-based design projects. Academia E-MBA from M-Power, B-School, Chennai in 2008. B.Tech. (Mechanical) from Y.C.M.O.U., Nasik in 2008. Diploma in Mechanical Engineering from BTE, Mumbai in 1996. Personal Dossier Date of Birth: 30th November 1976 Permanent Address: Flat No. 302, Kalindi-A, Dishanagari, Near MIT College, Beed Bypass Road- 431001, Aurangabad Languages Known: Marathi, Hindi, Guajarati and English. ------------------------------------------------------------------------------------------------------------------------------------------------- *******************************************END************************************************** Key Result & Notable Highlights in Krupa Technologies: