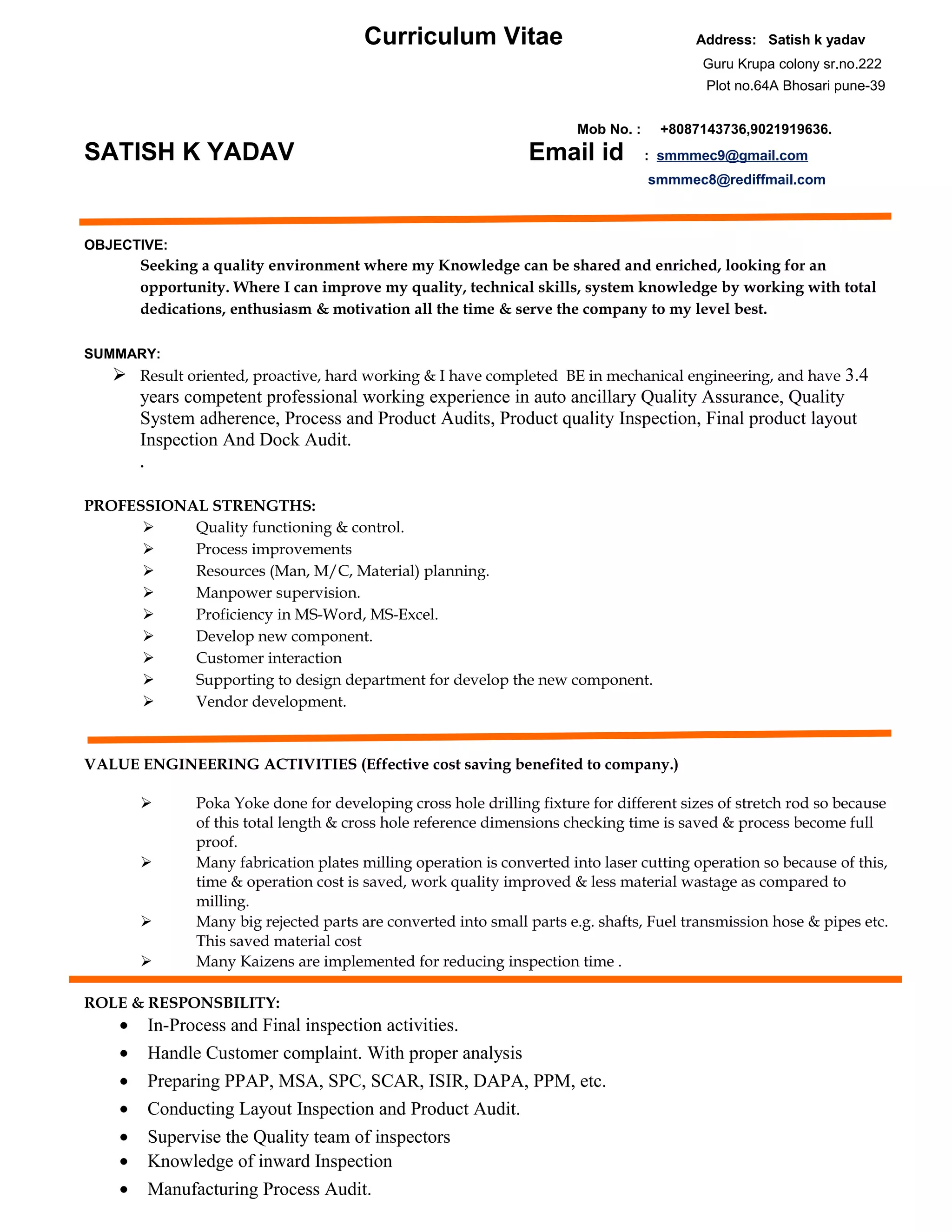

- Satish K Yadav is seeking a quality role where he can utilize his 3.4 years of experience in quality assurance, quality systems, process and product audits, and inspection. He has a Bachelor's degree in Mechanical Engineering.

- His professional strengths include quality control, process improvement, resource planning, supervision, and proficiency in MS Office applications. He has experience in new product development, customer interaction, and vendor development.

- He has worked as a Quality Engineer at Saki Auto Products Pvt Ltd, a manufacturer of automotive components, where he handled tasks like inspection, complaint resolution, documentation, process audits, and vendor management to ensure defect-free quality production.