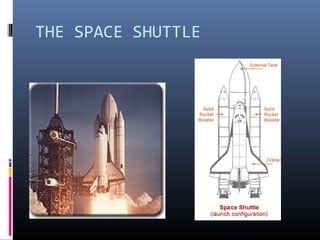

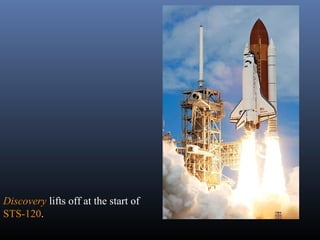

The space shuttle, first launched in April 1981, is the world's only reusable spacecraft designed to transport cargo and astronauts to orbit, and has conducted approximately 100 missions. Key components include the orbiter, external tank, and solid rocket boosters, with the main engines providing significant thrust and advanced technology for space operations. The shuttle has played a crucial role in various scientific and military missions throughout its operational history.

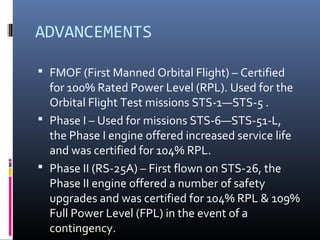

![A Block II RS-25D Main

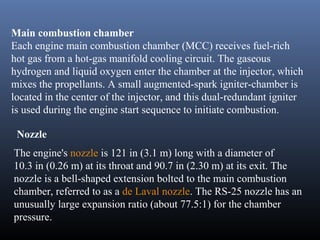

Engine Controller

Each engine is equipped with a

Main Engine Controller (MEC), an

integrated computer which controls

all of the engine's functions

(through the use of valves) and

monitors its performance. Built by

Honeywell Aerospace, each MEC

originally comprised two redundant

Honeywell HDC-601 computers,

[11] later upgraded to a system

composed of two doubly

redundant Motorola 68000

(M68000) processors (for a total of

4 M68000s per controller).](https://image.slidesharecdn.com/spaceshuttlesadvancement-140920094933-phpapp01/85/Space-Shuttles-Advancement-22-320.jpg)