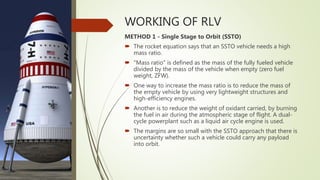

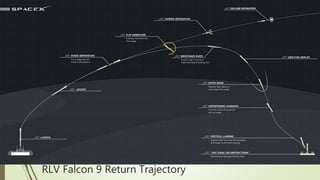

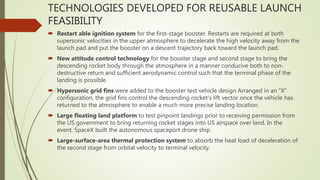

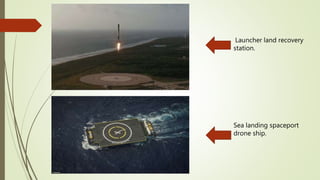

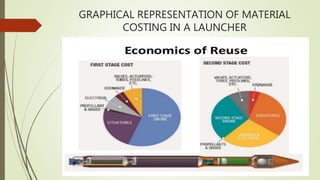

The document discusses the concept of reusable launch vehicles (RLVs), which are designed for multiple missions to reduce the cost of space travel. It outlines the historical development of RLV technology, current advancements by companies like SpaceX, and various methods for achieving reusability such as single-stage and two-stage to orbit designs. The document also addresses the challenges and economics associated with developing RLVs, emphasizing the potential for significant cost reductions in accessing space.