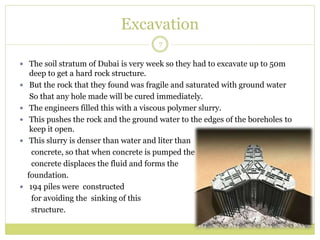

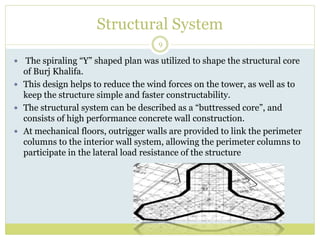

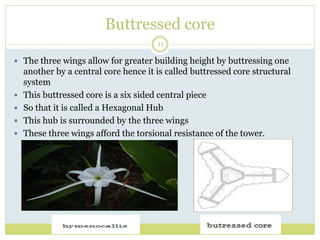

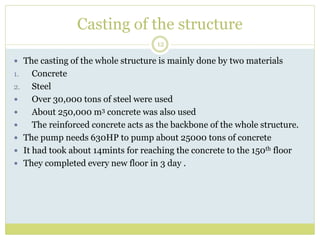

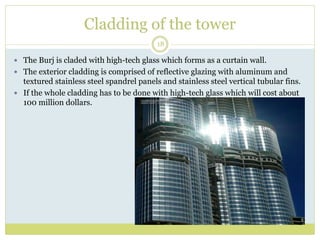

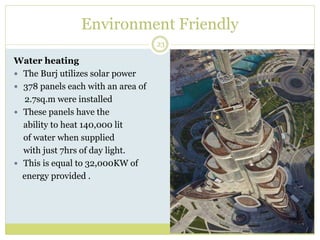

The document provides details about the Burj Khalifa, the tallest man-made structure in the world located in Dubai. It discusses the project details like its height of 828 meters with 162 floors. It outlines the various engineering challenges faced in its construction due to the hot climate and loose soil conditions. It describes the deep foundation system using large concrete piles and the buttressed core structural system used. It also summarizes the concrete and steel quantities used, fast construction methodology, cladding and environmental features of the Burj Khalifa.